Team:Calgary/Project/Synergy

From 2012.igem.org

| Line 73: | Line 73: | ||

TITLE=Synergy: Putting it all Together|CONTENT= | TITLE=Synergy: Putting it all Together|CONTENT= | ||

<html> | <html> | ||

| - | <img src="https://static.igem.org/mediawiki/2012/0/03/UCalgary2012_FRED_and_OSCAR_Synergy.png" style="padding: 10px; float: right;"></img> | + | <img src="https://static.igem.org/mediawiki/2012/0/03/UCalgary2012_FRED_and_OSCAR_Synergy.png" style="padding: 10px; width: 280px; float: right;"></img> |

<h2>Incorporating human practices in the design of our system </h2> | <h2>Incorporating human practices in the design of our system </h2> | ||

<p>In the earlier stages of our project, we realized that in order to give our project the best chance of being implemented, we needed to do it in a way that was in line with both industry’s wants and needs. To ensure that we did this, we established a dialogue with several experts in order to get their opinions on how we should approach our project. This led to an <b>informed design</b> of our system, in which we emphasized the need for both physical and genetic containment devices. </p> | <p>In the earlier stages of our project, we realized that in order to give our project the best chance of being implemented, we needed to do it in a way that was in line with both industry’s wants and needs. To ensure that we did this, we established a dialogue with several experts in order to get their opinions on how we should approach our project. This led to an <b>informed design</b> of our system, in which we emphasized the need for both physical and genetic containment devices. </p> | ||

Revision as of 00:15, 27 October 2012

Hello! iGEM Calgary's wiki functions best with Javascript enabled, especially for mobile devices. We recommend that you enable Javascript on your device for the best wiki-viewing experience. Thanks!

Synergy: Putting it all Together

Incorporating human practices in the design of our system

In the earlier stages of our project, we realized that in order to give our project the best chance of being implemented, we needed to do it in a way that was in line with both industry’s wants and needs. To ensure that we did this, we established a dialogue with several experts in order to get their opinions on how we should approach our project. This led to an informed design of our system, in which we emphasized the need for both physical and genetic containment devices.

Have we accomplished our goal?

Nearing the end of our project however, we wanted to see if we had accomplished what we set out to do. So we decided to go back to the experts, this time taking the progress we’ve made on our project with us. We got a variety of different perspectives from suggestions on the...... The results of all of these can be found on our Interviews page. One major concern was scale-up. One expert wanted to know how feasible this system would actually be. We have some FRED components, we have OSCAR components, and we have some killswitch components, but how functional are some of these parts, and how do they work together. So our next major goal was to establish synergy: try to put some of these pieces together in order to assess how far we’d actually gotten.

Putting FRED together

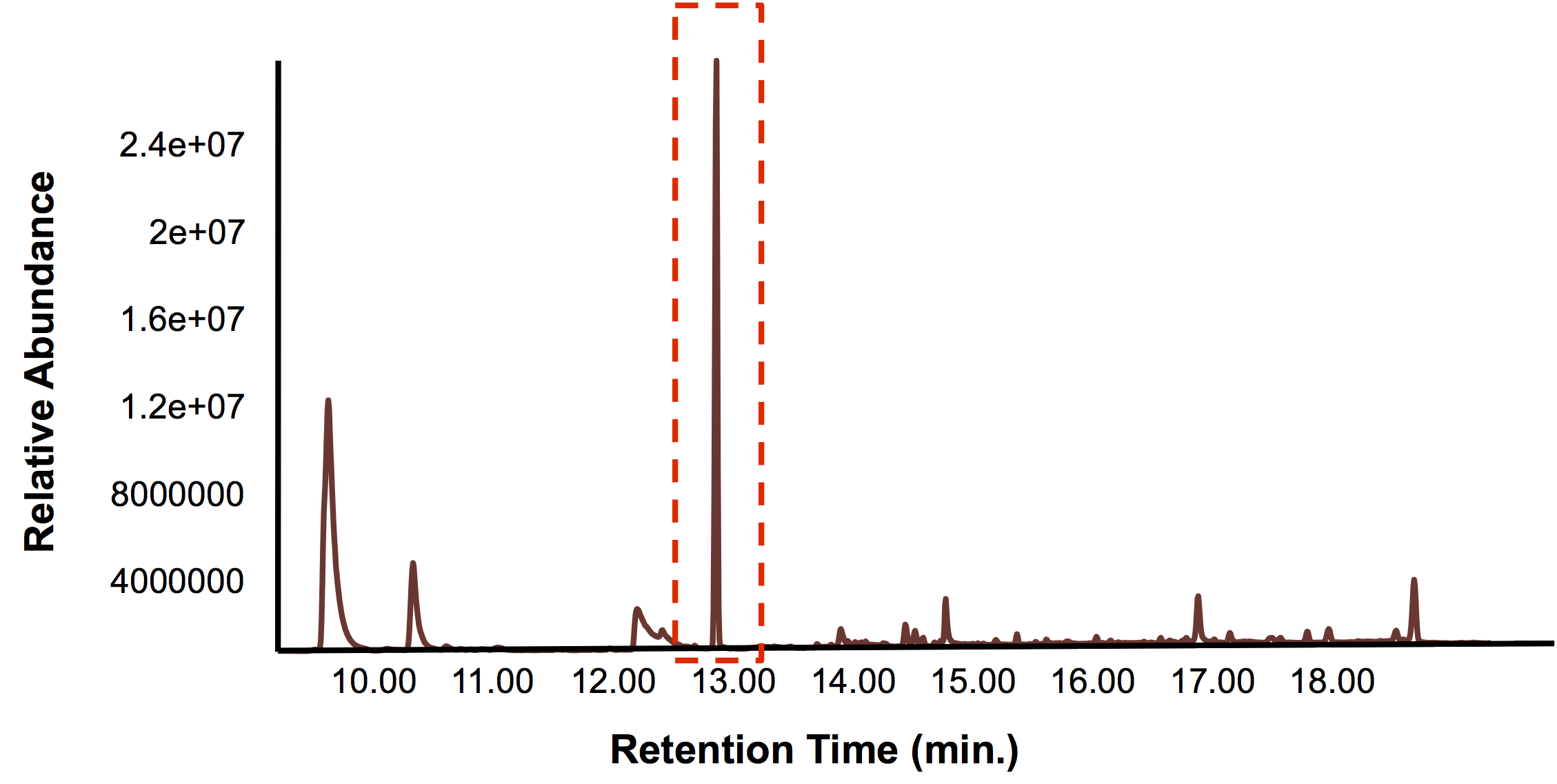

Now that we’ve been able to show that we can indeed sense three compounds electrochemically and simultaneously using our hydrolase system, our next goal was to actually try to sense toxins. Despite the fact that we have encountered significant difficulty in trying to sequence our transposon clones, given hat

Can we sense toxins in tailings ponds?

Putting together our killswitches

Our flux-based analysis allowed us to realize the potential for glycine to be used not only as a way to increase the yield of OSCAR, but also as an auxotrophic killswitch. This allowed our model to be used not only to inform our wetlab, but also our human practices. We wanted to see how this auxotrophic marker system could work with one of our inducible killswitch constructs. So we transformed our rhamnose inducible killswitch construct containing S7 (BBa_K902084) into our glycine knockout strain and attempted to characterize cell death over a variety of conditions.

Putting our Killswitch into OSCAR

The next thing we wanted to validate was that our glycine knockout strain would in fact work as we wanted it to in OSCAR. Namely, we wanted to know if putting the PetroBrick into our glycine knockout strain and growing it in the presence of glycine would still give us the same increased hydrocarbon production that we saw when validating our model. We transformed the PetroBrick into the knockout strain and repeated the PetroBrick validation assay protocol. Our results are shown below:

Taking FRED out to the field!

Once we knew that FRED could actually detect toxins found in tailings ponds within a laboratory setting, the next challenge would be to take FRED out to a tailings pond to out him to the test. Unfortunately, there are very strict regulations surrounding tailings ponds, and the publication of information pertaining to their contents. As such, obtaining permissions for a tailing pond field test was not possible within the time frame of our project. We still felt that testing FRED out in the real world, demonstrating that our prototype was easy to use and functional outside of a lab environment was extremely important. As such, we decided to do a field test of a body of water in our own city. The first thing we worried about though, was if there was any regulation surrounding water sampling, or performing a field test with a genetically modified organism (GMO). So we did a literature search to look for any regulations that might exist. We couldn’t find anything that pertained to our province, so we looked to Ontario and the United States. We looked at the concise guide to U.S. federal guidelines, rules and regulations for synthetic biology. In this guide, rules pertaining to field tests are covered. In cases where organisms are going to be released into the environment, the EPA (environmental protection agency) requires a TSCA (Toxic Substances Control Act) Experimental Release Application (TERA) to be completed 60 days before the trial begins and the APHIS (Animal and Plant Health Inspection Service) requires a permit or notification.

Putting OSCAR in action!

Once we had tested FRED and showed that he is not only able to , we wanted to put OSCAR into action and who that the design of our bioreactor was capable of doing what we wanted it to. By the end of the summer, we had a lab scale prototype and design for our bioreactor. To help us move forward with this portion of the project we interviewed Kelly Roberge, a consultant for oil sands specializing in tailings ponds. This interview gave us much to think about and helped us form ideas on how to improve the overall design of our bioreactor. In particular, Kelly’s advice and questions surrounded scaling up our bioreactor to industrial size. There are many things to consider when going from lab scale to industrial scale, and very little can be correlated linearly when moving from lab scale to industrial size (1000L+ tanks). To start, we would have to consider the amount of naphthenic acids needed to provide steady throughput in our system, and how much hydrocarbon can be produced in a full cycle of our system. To help provide theoretical solutions to these issues, we could determine the hydrocarbon output of our lab scale experiments once they are up and running to get an idea of what kind of numbers we are dealing with. In addition, we will have to take into consideration the composition of tailings pond solution, especially the sludge and bitumen content. This sludge could be harmful to our bioreactor and reduce the efficiency as well. One way we could solve this problem is by utilizing current NFT drying techniques used to help degrade tailings ponds. A sludge reduced water runoff is the result of this process. This water runoff could be the input to our system, which still contains large quantities of naphthenic acids. This would help increase the efficiency of our bioreactor and even allow scale up to be possible.

"

"