Team:Calgary/Project

From 2012.igem.org

| (16 intermediate revisions not shown) | |||

| Line 28: | Line 28: | ||

<body> | <body> | ||

<h2>Toxins In Our Environment</h2> | <h2>Toxins In Our Environment</h2> | ||

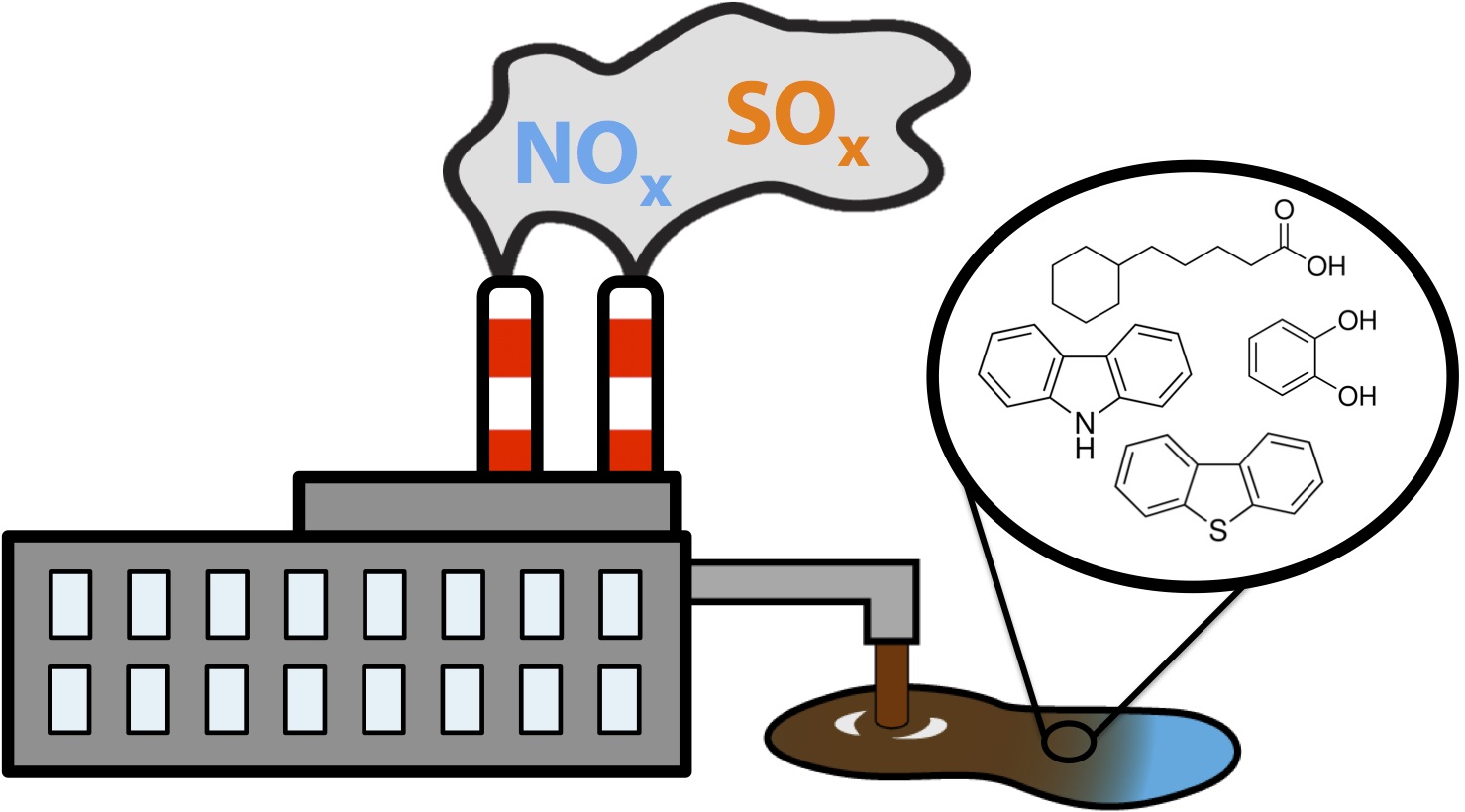

| - | <p>During petroleum extraction and refinement processes, toxic byproducts are produced. These compounds have | + | <p>During petroleum extraction and refinement processes, toxic byproducts are produced. These compounds have an enormous environmental impact, burdening our ecosystems with land, water, and air contamination. |

Common forms of air pollutants consist of NO<sub>x</sub> (nitrogen containing compounds) and SO<sub>x</sub> (sulfur containing compounds) which contribute to green house gas accumulation and acid rain (Schneider, 2006; Environmental protection agency, 1999). | Common forms of air pollutants consist of NO<sub>x</sub> (nitrogen containing compounds) and SO<sub>x</sub> (sulfur containing compounds) which contribute to green house gas accumulation and acid rain (Schneider, 2006; Environmental protection agency, 1999). | ||

| - | Similarly, land and water contaminants often consist of complex mixtures including highly toxic phenols and aromatic compounds, toxic and corrosive carboxylic acids (naphthenic acids) as well as sulfur and nitrogen-containing compounds. These often are recalcitrant, having complex structures that are difficult to break down, | + | Similarly, land and water contaminants often consist of complex mixtures including highly toxic phenols and aromatic compounds, toxic and corrosive carboxylic acids (naphthenic acids) as well as sulfur and nitrogen-containing compounds. These often are recalcitrant, having complex structures that are difficult to break down, which causes them to persist in the ecosystem. Classical examples of water contamination include tailings ponds, which contain byproducts from the bitumen extraction process of oil sands. Although the water in tailings ponds is recycled to the extraction process, it is not treated to remove the toxins but kept contained in the ponds. This creates a susceptibility toward contamination of surrounding areas as a result of these toxic compounds leaching into ground water sources, through spills or through the accidental release of waste products into the environment. </p> |

| Line 39: | Line 39: | ||

<h2>Synthetic Biology As A Platform For Remediation</h2> | <h2>Synthetic Biology As A Platform For Remediation</h2> | ||

| - | <p>The removal of these compounds is becoming | + | <p>The removal of these compounds is becoming increasingly important, especially as government bodies start to become more proactive, implementing stricter regulation. Presently, there are a variety of solutions to remove these compounds from the environment by chemical means. These methods involve the use of chemical agents or the physical removal of contaminated soil or water samples and storing these products in contained areas (Scott <i>et al</i>. 2005). There is still however, no efficient, environmentally friendly mechanism for this to occur. The real question is,</p> |

| - | <p><b>What do we need | + | <p><b>What do we need to remediate these toxins from the environment?</b></p> |

| - | <p>We require a method to be able to easily and economically detect where these toxins are and then look to remediating them. Interestingly, microorganisms in the environment have evolved to be able to do both of these functions, responding to compounds in their environment and transforming them into food or other products. Harnessing these natural mechanisms through an engineered synthetic biology | + | <p>We require a method to be able to easily and economically detect where these toxins are and then look to remediating them. Interestingly, microorganisms in the environment have evolved to be able to do both of these functions, responding to compounds in their environment and transforming them into food or other products. Harnessing these natural mechanisms through an engineered synthetic biology thus becomes a viable option.</p> |

<p><b>What if we could detect toxins in our environment using a synthetically engineered organism? What if we could use a second organism to take these compounds and not only <u>degrade</u> them but convert them into <u>useful</u> compounds like hydrocarbons!</b></p> | <p><b>What if we could detect toxins in our environment using a synthetically engineered organism? What if we could use a second organism to take these compounds and not only <u>degrade</u> them but convert them into <u>useful</u> compounds like hydrocarbons!</b></p> | ||

| Line 53: | Line 53: | ||

<p> | <p> | ||

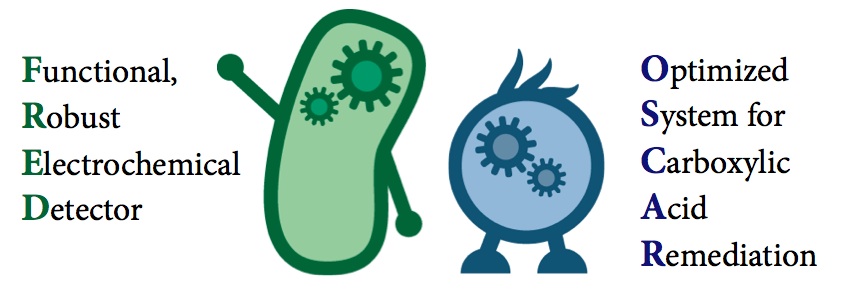

| - | We would like to introduce FRED and OSCAR! Our dynamic biosensor/bioreactor duo designed | + | We would like to introduce FRED and OSCAR! Our dynamic biosensor/bioreactor duo is designed to detect toxic compounds such as the ones illustrated above in liquid waste and contaminated waters and to convert these toxic components into usable hydrocarbons. FRED, the Functional Robust Electrochemical Detector, is capable of detecting various toxic components simultaneously through an electrochemical response. Building on the single output <a class="blue" href="https://2011.igem.org/Team:Calgary">biosensor for NAs</a> that we developed last year, we set out to design a multiple output biosensor. We illustrated how this sensor could work by showing that it has the potential to detect multiple toxins in contaminated water. Additionally, we developed a miniaturized circuit of the potentiostat for the prototype, validated this device in the wetlab, and designed our own software, which we have made available to everyone. |

</p> | </p> | ||

<p> | <p> | ||

| - | OSCAR, the Optimized System for Carboxylic Acid Remediation, is designed specifically to target toxins such as naphthenic acids (carboxylic acid-containing compounds), catechol, and nitrogen and sulfur | + | OSCAR, the Optimized System for Carboxylic Acid Remediation, is designed specifically to target toxins such as naphthenic acids (carboxylic acid-containing compounds), catechol, and nitrogen and sulfur containing heterocyclic compounds. Using the PetroBrick (<a href="http://partsregistry.org/wiki/index.php?title=Part:BBa_K590025">BBa_K590025</a>) we were able to convert various naphthenic acid based compounds into their hydrocarbon analogs. Additionally, we wanted to be able to degrade other toxic components of tailings so we used the <i>xylE</i> gene (<a href="http://partsregistry.org/wiki/index.php?title=Part:BBa_J33204">BBa_J33204</a>) in order to cleave catechol, an abundant intermediate in many toxic areas. Not only did we set out to break down catechol, but we attempted to see if we could further reduce the toxicity of the catechol breakdown product through use of the PetroBrick. When we co-culture these genetic circuits we can selectively produce new compounds from catechol compared to with <i>xylE</i> alone, suggesting that the Petrobrick may be used to create new hydrocarbon based compounds! Lastly we wanted to remove sulfur and nitrogen from heterocycles using the <i>dsz</i> and <i>carA</i> operons respectively. Not only would this improve the quality of fuel produced, but also prevent the production of NO<sub>x</sub> and SO<sub>x</sub> during combustion, reducing the amount of air pollution produced from burning fuel. </p> |

<h2>Taking A Step Back - Human Practices Inspired Our Project!</h2> | <h2>Taking A Step Back - Human Practices Inspired Our Project!</h2> | ||

<img src="https://static.igem.org/mediawiki/2012/1/17/UCalgary2012_FRED_and_OSCAR_HP.png" style="float: right; width: 200px; padding: 10px;"></img> | <img src="https://static.igem.org/mediawiki/2012/1/17/UCalgary2012_FRED_and_OSCAR_HP.png" style="float: right; width: 200px; padding: 10px;"></img> | ||

| - | <p>Before starting our project, the Calgary iGEM team felt it would be important to <a href="https://2012.igem.org/Team:Calgary/Project/HumanPractices">answer a few questions</a> about how FRED and OSCAR could be applied | + | <p>Before starting our project, the Calgary iGEM team felt it would be important to <a href="https://2012.igem.org/Team:Calgary/Project/HumanPractices">answer a few questions</a> about how FRED and OSCAR could be applied in the oil and gas sector.</p> |

| - | <p><b>Would oilsands industry be interested in a biosensor and bioreactor for remediation purposes?</b> Yes! | + | <p><b>Would oilsands industry be interested in a biosensor and bioreactor for remediation purposes?</b> Yes! Our meeting with the Oilsands Leadership Initiative (OSLI) has affirmed that industry is interested in potentially using synthetic biology for remediation of toxins.</p> |

| - | <p><b>What would people think about using synthetic biology<img src="https://static.igem.org/mediawiki/2012/e/e8/UCalgary2012_FRED_and_OSCAR_Interviews_Low-Res.png" style="float: right; padding: 10px; width: 200px;"></img> in the oilsands? Do they have any concerns about its implementation?</b> We consulted with two professionals working in biotechnology and ecological development in Alberta. Both of them | + | <p><b>What would people think about using synthetic biology<img src="https://static.igem.org/mediawiki/2012/e/e8/UCalgary2012_FRED_and_OSCAR_Interviews_Low-Res.png" style="float: right; padding: 10px; width: 200px;"></img> in the oilsands? Do they have any concerns about its implementation?</b> We consulted with two professionals working in biotechnology and ecological development in Alberta. Both of them emphasized that while the concept sounds great, it is important that we keep in mind the safety and ethics of our project.</p> |

| - | <p><b>How can OSCAR and FRED be designed with safety in mind?</b> From our various conversations our team looked | + | <p><b>How can OSCAR and FRED be designed with safety in mind?</b> From our various conversations our team looked toward both physical <img src="https://static.igem.org/mediawiki/2012/c/c3/UCalgary2012_FRED_and_OSCAR_Design.png" style="float: right; padding: 10px; width: 200px;"></img>and genetic design considerations to ensure that from the outset, both FRED and OSCAR were designed in a safe and functional way. This involved incorporating physical containment features in the biosensor and bioreactor designs and employing biological kill switch mechanisms.</p> |

| - | <p><b>How can we teach people more about FRED, OSCAR, and Synthetic Biology?</b> From our interviews it was clear that not many people knew | + | <p><b>How can we teach people more about FRED, OSCAR, and Synthetic Biology?</b> From our interviews it was clear that not many people knew about synthetic biology or its applications in the oil and gas sector. For this we partnered with the Telus Spark Centre, the local Science Centre in Calgary, to help communicate synthetic biology to them. We also developed a video game that had its debut at the centre and educated adults and kids on synthetic biology in a fun way! </p> |

<h2>Learn More About FRED and OSCAR</h2> | <h2>Learn More About FRED and OSCAR</h2> | ||

Latest revision as of 01:51, 27 October 2012

Hello! iGEM Calgary's wiki functions best with Javascript enabled, especially for mobile devices. We recommend that you enable Javascript on your device for the best wiki-viewing experience. Thanks!

Project Overview

Toxins In Our Environment

During petroleum extraction and refinement processes, toxic byproducts are produced. These compounds have an enormous environmental impact, burdening our ecosystems with land, water, and air contamination. Common forms of air pollutants consist of NOx (nitrogen containing compounds) and SOx (sulfur containing compounds) which contribute to green house gas accumulation and acid rain (Schneider, 2006; Environmental protection agency, 1999). Similarly, land and water contaminants often consist of complex mixtures including highly toxic phenols and aromatic compounds, toxic and corrosive carboxylic acids (naphthenic acids) as well as sulfur and nitrogen-containing compounds. These often are recalcitrant, having complex structures that are difficult to break down, which causes them to persist in the ecosystem. Classical examples of water contamination include tailings ponds, which contain byproducts from the bitumen extraction process of oil sands. Although the water in tailings ponds is recycled to the extraction process, it is not treated to remove the toxins but kept contained in the ponds. This creates a susceptibility toward contamination of surrounding areas as a result of these toxic compounds leaching into ground water sources, through spills or through the accidental release of waste products into the environment.

Synthetic Biology As A Platform For Remediation

The removal of these compounds is becoming increasingly important, especially as government bodies start to become more proactive, implementing stricter regulation. Presently, there are a variety of solutions to remove these compounds from the environment by chemical means. These methods involve the use of chemical agents or the physical removal of contaminated soil or water samples and storing these products in contained areas (Scott et al. 2005). There is still however, no efficient, environmentally friendly mechanism for this to occur. The real question is,

What do we need to remediate these toxins from the environment?

We require a method to be able to easily and economically detect where these toxins are and then look to remediating them. Interestingly, microorganisms in the environment have evolved to be able to do both of these functions, responding to compounds in their environment and transforming them into food or other products. Harnessing these natural mechanisms through an engineered synthetic biology thus becomes a viable option.

What if we could detect toxins in our environment using a synthetically engineered organism? What if we could use a second organism to take these compounds and not only degrade them but convert them into useful compounds like hydrocarbons!

Introducing...

We would like to introduce FRED and OSCAR! Our dynamic biosensor/bioreactor duo is designed to detect toxic compounds such as the ones illustrated above in liquid waste and contaminated waters and to convert these toxic components into usable hydrocarbons. FRED, the Functional Robust Electrochemical Detector, is capable of detecting various toxic components simultaneously through an electrochemical response. Building on the single output biosensor for NAs that we developed last year, we set out to design a multiple output biosensor. We illustrated how this sensor could work by showing that it has the potential to detect multiple toxins in contaminated water. Additionally, we developed a miniaturized circuit of the potentiostat for the prototype, validated this device in the wetlab, and designed our own software, which we have made available to everyone.

OSCAR, the Optimized System for Carboxylic Acid Remediation, is designed specifically to target toxins such as naphthenic acids (carboxylic acid-containing compounds), catechol, and nitrogen and sulfur containing heterocyclic compounds. Using the PetroBrick (BBa_K590025) we were able to convert various naphthenic acid based compounds into their hydrocarbon analogs. Additionally, we wanted to be able to degrade other toxic components of tailings so we used the xylE gene (BBa_J33204) in order to cleave catechol, an abundant intermediate in many toxic areas. Not only did we set out to break down catechol, but we attempted to see if we could further reduce the toxicity of the catechol breakdown product through use of the PetroBrick. When we co-culture these genetic circuits we can selectively produce new compounds from catechol compared to with xylE alone, suggesting that the Petrobrick may be used to create new hydrocarbon based compounds! Lastly we wanted to remove sulfur and nitrogen from heterocycles using the dsz and carA operons respectively. Not only would this improve the quality of fuel produced, but also prevent the production of NOx and SOx during combustion, reducing the amount of air pollution produced from burning fuel.

Taking A Step Back - Human Practices Inspired Our Project!

Before starting our project, the Calgary iGEM team felt it would be important to answer a few questions about how FRED and OSCAR could be applied in the oil and gas sector.

Would oilsands industry be interested in a biosensor and bioreactor for remediation purposes? Yes! Our meeting with the Oilsands Leadership Initiative (OSLI) has affirmed that industry is interested in potentially using synthetic biology for remediation of toxins.

What would people think about using synthetic biology in the oilsands? Do they have any concerns about its implementation? We consulted with two professionals working in biotechnology and ecological development in Alberta. Both of them emphasized that while the concept sounds great, it is important that we keep in mind the safety and ethics of our project.

in the oilsands? Do they have any concerns about its implementation? We consulted with two professionals working in biotechnology and ecological development in Alberta. Both of them emphasized that while the concept sounds great, it is important that we keep in mind the safety and ethics of our project.

How can OSCAR and FRED be designed with safety in mind? From our various conversations our team looked toward both physical  and genetic design considerations to ensure that from the outset, both FRED and OSCAR were designed in a safe and functional way. This involved incorporating physical containment features in the biosensor and bioreactor designs and employing biological kill switch mechanisms.

and genetic design considerations to ensure that from the outset, both FRED and OSCAR were designed in a safe and functional way. This involved incorporating physical containment features in the biosensor and bioreactor designs and employing biological kill switch mechanisms.

How can we teach people more about FRED, OSCAR, and Synthetic Biology? From our interviews it was clear that not many people knew about synthetic biology or its applications in the oil and gas sector. For this we partnered with the Telus Spark Centre, the local Science Centre in Calgary, to help communicate synthetic biology to them. We also developed a video game that had its debut at the centre and educated adults and kids on synthetic biology in a fun way!

Learn More About FRED and OSCAR

To learn more about our team see the data page, or the FRED and OSCAR overview pages below.

"

"