Team:Bielefeld-Germany/Safety

From 2012.igem.org

1. Would any of your project ideas raise safety issues in terms of

- researcher safety,

- public safety, or

- environmental safety?

The listed organisms we use (or from which we use parts) are all part of the basic biosafety level 1:

- Pichia pastoris WT X33 [3]

- Pichia pastoris GS115 [3]

- Aequeora victoria [1]

- Cellulomonas fimi ATCC 484 [2]

- Clostridium cellulovorans [1]

- Escherichia coli BL21 (DE3)

- Thermus thermophilus HB27 [1]

- Bacillus halodurans C-125 [1]

- Bacillus pumilus DSM 27 (ATCC7061) [1]

- Xanthomonas campestris pv. campestris B100 [1]

- Streptomyces lavendulae REN-7

- Streptomyces griseus IFO 13350 [3]

- Arabidopsis thaliana Col-0

- Trametes versicolor [1]

For assuring safety of the researchers every team member has to take part in special lab safety training. This training includes theoretical and practical parts where the team members learn how to handle (harmful) chemicals, rules for handling the setups and general safety regulations which have to be considered in the lab, amongst others where we can find the material safety data sheets, how to handle the database with all the chemicals used in our lab and manuals for the devices.

Furthermore everyone is required to be informed in detail about the properties of every used chemical reagent. This implies that everyone has to read the R/S phrases and consider the recommended safety regulations.

To protect the researcher every person in the lab is required to wear safety clothes which implies long pants, closed shoes, a lab coat, safety glasses and when necessary gloves.

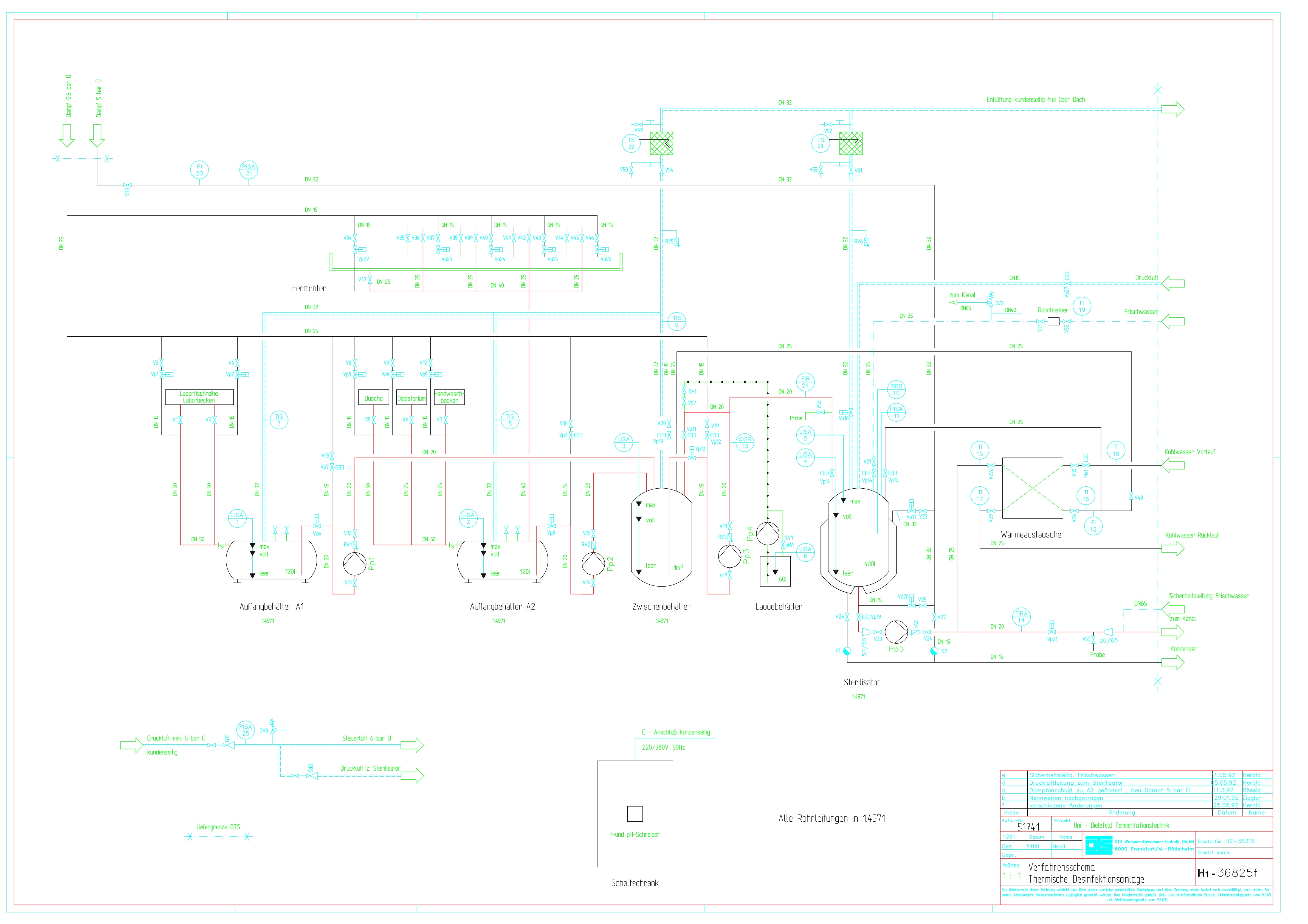

Other students and people without the authority and training do not have access to our iGEM lab. We take care that no organisms which are biological modified leave the lab. In the case that samples, chemicals or something else need to be transferred to another lab in order to continue an experiment we use special containers. For example, solvents are carried in buckets and samples in closed containers. Our project does not include the work with infectious organisms. Cell material is collected in glass bottles, which can be autoclaved or they can be disposed in a special sink, which is connected to a thermal disinfection system from EnviroDTS.

In our project we have to work with harmful chemicals. To avoid exposure we have to take special care, for example using gloves or breathing masks if necessary. The most harmful chemicals are listed below with the material safety data sheet (chemdb.de):

- Ethidium bromide for staining the DNA-gel

- Acrylamide in the SDS-PAGE

- Copper chloride in the culture medium for the fermentation

To characterize our produced enzymes we chose different substrates. Among the substrate are some harmful compounds:

- Estradiol: toxic

- Estrone: toxic

- Ethinylestradiol: toxic

- Diclofenac: toxic

- Ibuprofen: harmful to health

- Naproxen: harmful to health

- Naphthalene: harmful to health and dangerous to environment

- Acenaphthene: dangerous to environment

- Phenanthrene: dangerous to environment

- Anthracene: irritant and dangerous to environment

- Lindane: toxic and dangerous to environment

These chemicals are stored in the lab taking into account the pertaining safety regulations. Therefore, solvents are stored in explosion protected lockers and toxic chemicals are locked away separately. Of course all chemicals are adequately labeled. Work with harmful chemicals, especially the handling of solvents, is done under a fume hood. Process steps which require the protection from contaminations are carried out under a clean bench.

Some experiments are carried out in special areas in the lab. One example is ethidium bromide which we use for staining our gels. We only use the chemical in a special marked area of our lab and have separate equipment to prevent exposure abd transfer.

As already mentioned above, we also care about the environment. Therefore, all chemicals are disposed regarding their properties such as toxicity and explosiveness. All chemicals and chemically contaminated trash is disposed by the chemical disposal department. The department is also able to recycle solvents, such as ethanol and acetone (requires only a low grade of contamination). In this case we can get the distilled solvents, labeled as technical solvents, back and can use them for experiments or applications where the pureness is not a crucial factor.

Laccases are known to have a broad spectrum of activity. One is the possible degradation of estrogen or other chemical compounds to degradation products with unknown effects. To eliminate the occurrence of toxic degradation products the laccases will be characterized with a broad range of substrates and the degradation products will be analyzed with improved substrate analytics.

In a future application our laccases could be detached from the immobilization material for example if the CBD (cellulose binding domain) is not strong enough. If they are washed out into the drinking water there is the possibility of public exposure. Usage of laccases in the food industry[4] suggests that there is no issue with the consumption of laccases. But not knowing which degradation products will be generated, it is a critical issue we have to observe. The plan is, to detemine flow rates at which the laccases will not be detached and compare them with the typical flow rates of a wastewater treatment plant we got from the sewage treatment plant Schloß-Holte. For further tests we will use the lab-scale sewage-treatment plant

In summary, we take care about the safety of ourselves, try to work as cleanly as possible and take care to cause no harm to the environment. The rules and safety measures we consider are standard at the Bielefeld University as well as in Germany.

2. Do any of the new BioBrick parts (or devices) that you made this year raise any safety issues? If yes,

- did you document these issues in the Registry?

- how did you manage to handle the safety issue?

- How could other teams learn from your experience?

No, none of the new BioBrick parts that we constructed this year raise any safety issues. Although we are working with a plant pathogen organism (Xanthomonas campestris pv. campestris B100), the laccase we are using is a harmless enzyme. Moreover the enzyme laccase of Trametes versicolor is intended for use in the food-processing industry, for example for bakery products and drinks. Furthermore the organisms we used to isolate laccases and our production strain Escherichia coli KRX are S1 organisms, which are not able to survive outside the lab conditions. This is a requirement for S1 organisms (list of these organisms) defined by the German genetic engineering security act (GenTSV):

Biosecurity stage 1 Organisms

- are not human, phyto or animal pathogenic

- do not contain or release organisms of a higher risk stage

- are approved by experiments or long term evaluation or do not proliferate in the environment because of biological implanted boundaries.

3. Is there a local biosafety group, committee, or review board at your institution?

- If yes, what does your local biosafety group think about your project?

- If no, which specific biosafety rules or guidelines do you have to consider in your country?

There is no Biosafety Committee at our university, only a bio-safety officer. Nevertheless, we have an iGEM instructor, Dr. Jörn Kalinowski, who is being informed about the project progress regularly and is responsible for the bio-safety of our project. Due to this fact he held a safety instruction seminar prior to our work. Also, our university has implemented a number of teams who take care of waste management and fire safety.

The general rule at our university is that before every lab course every student has to take part in specific safety training for the course. Further, once a year, depending on the field of study and research, every member of a lab is required to take a refreshment course in lab safety, bio safety, fire safety, waste management, handling gas cylinders and working with hazardous materials. All safety classes include a presentation and a practical part. For example in fire safety every student practices how to use the different types of fire distinguisher.

Before we (the iGEM team) started our lab work we took part at a general lab safety training course. Also, we had specific training for working with genetically modified organisms (GMOs) which is regulated in Germany by a number of laws like the law of genetic engineering. The work with GMOs has to be documented carefully. Handling, decontamination and disposal of GMOs is strictly regulated. According to the guidelines genetically modified organisms and contaminated materials can only leave the lab after decontamination via autoclavation. We make sure that all of our work is done considering the relevant rules and regulations.

The Federal office of consumer protection and safety (Federal office of consumer protection and safety in English) is the institution responsible for biosafety at universities, institutions etc. All laws, regulations and guidelines can be found here:

- National German laws and regulations

- European regulations and guidelines

- International contracts and agreements

The Federal office of consumer protection and safety appoints a team of experts (ZKBS, Zentrale Kommission für die Biologische Sicherheit) who determine the risks of GMOs for humans, animals and the environment. Based on their results they can suggest rules and regulations for handling GMOs.

ZKBS in English

4. Do you have any other ideas how to deal with safety issues that could be useful for future iGEM competitions? How could parts, devices and systems be made even safer through biosafety engineering?

During brainstorming to realize our project we got the idea to build a symbiosis reactor. We imagined that both organisms could not survive without each other outside the reactor. This idea could pose a greater biosafety in the lab for the researcher himself, for the public and the environment. Although it could have been a further step for better saftey application we decided not to follow this idea.

Further, everyone should be aware that we are not able to estimate the effects of releasing genetically modified organisms in the environment. That is why we work with a cell free system. Probably, it would be much easier to immobilize the organism itself directly in the filter but we decided to isolate the enzymes due to environmental safety.

References

[1] Einstufung von Bakterien in Risikogruppen, Bundesarbeitsblatt 10/2002

[2] COLECCIÓN ESPAÑOLA DE CULTIVOS TIPO, www.cect.org/english/vbac.php?cect=4283&lan=en, on www.cect.org, Aug 30, 2012

[3] Bundesamt für Verbraucherschutz und Lebensmittelsicherheit, www.bvl.bund.de/DE/06_Gentechnik/03_Antragsteller/06_Institutionen_fuer_biologische_Sicherheit/01_ZKBS/03_Organismenliste/gentechnik_zkbs_organismenliste_node, on www.bvl.bund.de, Sep 5, 2012

[4] Johann F. Osma, José L. Toca-Herrera, Susana Rodriguez-Couto (2010), Uses of Laccases in the Food Industry, Enzyme Research 2010:1-8

| 55px | | | | | | | | | | |

"

"