Team:Bielefeld-Germany/Labjournal/week19

From 2012.igem.org

Contents |

Week 19 (09/03 - 09/09/12)

Monday September 3rd

- Team Cultivation & Purification:

- Made one half of the SDS-Pages of the flask cultivation from 08/30.

- Work on culture of E.coli KRX containing [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863000 BBa_K863000] (08/31) was continued and we performed the cell disruption by high-pressure homogeniser in 3 cycles. Then it was purificated by using a TALON column. The product was given to the activity team for analysis.

- Fermentation of E.coli KRX with His-tagged GFP for the cellulose binding team

- --> Settings: fermenter: Braun, autoinduction medium, 60µg/mL chloramphenicol, 3L, 37°C, stirrer on cascade to hold a pO2 of 50%, airflow: 2NF/m. This time we cultivated only for 9 hours and then decreased the temperature at 20°C for a better folding of the protein for 1 hour. We had some problems with cascade at the end of the fermentation.

- Cells of today's fermentation of His-tagged GFP were disrupted via high-pressure homogeniser and laccase was purified by using the Talon column. The flow-through fluoresced very strong, so that not that much of the protein had bound to the column. Conclusion: The column had to be reloaded.

- Fermentation of E.coli KRX containing [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863000 BBa_K863000].

- --> Settings: fermenter: Braun, autoinduction medium, 60µg/mL chloramphenicol, 3L, 37°C, stirrer on cascade to hold a pO2 of 50%, airflow: 2NF/m, 9 hours. We only cultivated 9 hours, because we saw that a great amount of our cells already died.

- Made precultures of E.coli KRX containing [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863000 BBa_K863000], [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863005 BBa_K863005] and one containing a plasmid with a fusion protein of cellulose binding domain and His-tagged GFP.

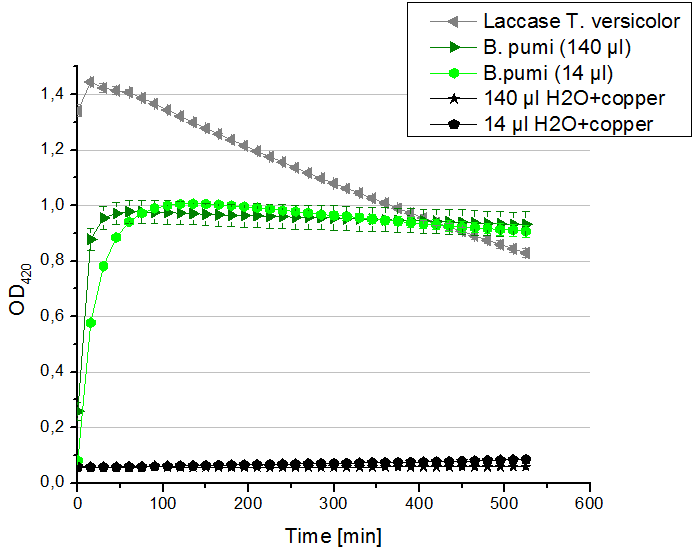

- Team Activity Tests: Today our hard-working Team Cultivation offered us some laccases from B. pumi. After fermentation and TALON purification the laccase was still hanging around in imidazole buffer, so we rebuffered it into nanopure water. We incubated the sample with copper and considered to measure the protein concentration before running the activity tests. Using the protocol for determining the protein concentration via Bradford (standards were 1 mg/ml, 1.5 mg/ml and 2 mg/ml BSA) we got a final B. pumi laccase concentration of 0.22 mg/ml. With this information we designed the following activity test different as usual. As a positive control we took 140 µl of our bought laccase from T. versicolor with a concentration of 0,021 mg/ml. Accordingly to this concentration we applied 14 µl of the B. pumi laccase to get approximately the same amount of laccase into each well. Additionally we tested 140 µl of the B. pumi laccase to make sure that we will definitely see any activity. After measuring the samples the whole night we got our results in the morning. It turned out, that our store bought laccase was rapidly active as seen before in our activity tests. The B. pumi laccase was also active. Using 140 µl of it led to the maximal state of oxidation of ABTS after 45 minutes. With the reduced amount of 14 µl of laccase this optimum was reached after 90 minutes. For our following activity tests we want to include the protein concentration again.

Tuesday September 4th

- We signed in for our tracks today! Our first choice is the 'Environment' track since it is obvious that we want to clean up drinking water and therefore help our environment. The second choice is the 'New Application' track. We are hoping our filter system can be applied in wastewater treatment plants and establishes a new area of water purification.

- Team Cultivation & Purification:

- Second half of the SDS-Pages of the flask cultivation from 08/30 was made.

- We reloaded our TALON column.

- After reloading we repeated the purification of BPUL produced by fermentation on 08/31. Therefore the flowthrough and the washing fraction were used. The different fractions should be tested by the activity team.

- A new fermentation of E.coli KRX containing [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863005 BBa_K863005] was started

- --> Settings: fermenter: Infors, autoinduction medium, 60µg/mL chloramphenicol, 3L, 37°C, stirrer on cascade to hold a pO2 of 50%, airflow: 2NF/m, 9 hours. We shorten the time, because the effect should be similar to the production of BPUL.

- The fermentation of E.coli KRX containing [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863000 BBa_K863000] and the one containing [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863005 BBa_K863005] were harvested and after centrifugation stored at 4°C, because our high-pressure homogeniser is out of work.

- Made a flask cultivation for the cellulose binding team: cultivation of E.coli KRX containing a plasmid with cellulose binding domain (CBD) fused to His-tagged GFP.

- -->Settings: 1L flask with baffles, autoinduction medium, 60µg/mL chloramphenicol, final volume: 250mL, 37°C, 120rpm, 9 hours. We made a three-fold determination, but did not get fluorescing cultures. The problem is to purify this product, because it might be impossible to remove the protein from the column. If it binds via CBD and not via His-tag.

- Made precultures of E.coli KRX containing plasmids with laccases from E.coli, B.pumilus and [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863012 BBa_K863012] behind a constitutive promoter as well as one containing [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863000 BBa_K863000]

Wednesday September 5th

- Team Cultivation & Purification:

- Performed the cell disruption of yesterday's flask cultivation to produce CBD-GFP+His fusion protein via sonification and made a SDS-Page of it. The problem is to purify this product, because it might be impossible to remove the protein from the column. If it binds via CBD and not via His-tag.

- Made a flask cultivation of E.coli KRX containing new BioBricks: Laccase from E.coli, B.pumilus and [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863012 BBa_K863012] behind a constitutive promoter.

- -->Settings: 100mL flask without baffles, autoinduction medium, 60µg/mL chloramphenicol, final volume: 60mL, 37°C, 120rpm, 12 hours, double determination.

- We repeated the purification of His-tagged GFP by using the flow-through and the washing fraction, but it did not work. Then we got to know that it could not work, because the sequencing showed us that the GFP was not tagged to His.

- Made a SDS-Page of the fractions of purified B.pumilus laccase produced at 09/03.

- Starting of another fermentation of [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863000 BBa_K863000]

to get a growth kinetics.

- -->Settings: fermenter: Braun, autoinduction medium, 60µg/mL chloramphenicol, 3L, 37°C, stirrer on cascade to hold a pO2 of 50%, airflow: 2NF/m, 6 hours. Found out that we got a maximal optical density after 4 hours, after which the cells start to die. Therefore we harvested the cells after 6 hours.

- Made preculture of E.coli KRX containing [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863005 BBa_K863005]

Thursday September 6th

- Team Cultivation & Purification:

- Fermentation of E.coli KRX containing [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863005 BBa_K863005] to get a growth kinetics

- -->Settings: fermenter: Infors, autoinduction medium, 60µg/mL chloramphenicol, 3L, 37°C, stirrer on cascade to hold a pO2 of 50%, airflow: 2NF/m.

- Preparation of the bigger fermenter (7L) for the first time

- Performing the cell disruption via sonification and the purification via HisTrap column supported by Äkta of the flask cultivation from 09/05.

- We got to know that the working group of physical chemistry has another homogeniser, that we could use. We performed the cell disruption via high-pressure homogeniser of fermentations from 09/03, 04 and 05.

- Made preculture of E.coli KRX containing [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863005 BBa_K863005]

Friday September 7th

- Team Cultivation & Purification:

- Today we performed lots of purifications. This time we used a Ni-NTA column, because it seemed to work better than the TALON column. Therefore it was reloaded newly before starting the purifications. The purified samples were: laccase B.pumilus produced on 09/03 and 09/05 as well as laccase E.coli produced on 09/04.

??MORE??

The results were not that promising, so maybe we harvested the cells too early. They start dying more or less when we expect them to produce our (toxic) protein. So we think we had to let some of them die, so that the rest will produce our protein. The next fermentations should endure at least 12 hours.

- Fermentation of E.coli KRX containing [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863005 BBa_K863005] within the big fermenter

- -->Settings: fermenter: Biostat NFL 3 (7L), autoinduction medium, 60µg/mL chloramphenicol, final volume: 6L, 37°C, stirrer increased 2% if the pO2 got below 30%, airflow: 5NF/m, 12 hours.

Saturday September 8th

- Team Cultivation & Purification:

- Harvesting and centrifugation of fermentation of 09/07. Pellet stored at 4°C.

MORE?

- Made precultures of E.coli KRX containing [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863005 BBa_K863005], [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863000 BBa_K863000] and of EcN012 cells? containing [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863012 BBa_K863012] and laccase from B.halodurans.

Sunday September 9th

- Team Cultivation & Purification:

- Fermentation of E.coli KRX containing [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863005 BBa_K863005] (fermenter: Infors) or containing [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863000 BBa_K863000] (fermenter: Braun) to get a growth kinetics

- --> Settings: autoinduction medium, 60µg/mL chloramphenicol, final volume: 3 L, 37 °C, stirrer on cascade to hold a pO2 of 50 %, airflow: 2 NF/m, 12 hours.

- Harvesting and centrifugation of today's 3L fermentations.

- Fermentation of E.coli KRX containing [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863000 BBa_K863000]

- --> Settings: fermenter: Biostat NFL3 (7L), autoinduction medium, final volume: 6L, 37°C, pH 7 stirrer increased 2% if the pO2 got below 30%, airflow: 5NF/m, 12 hours.

- Flask cultivation of EcN012 cells containing [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863012 BBa_K863012] and laccase from B.halodurans behind a constitutive promotor.

- --> Settings: flask without baffles, XXXX (medium, scale), 60µg/mL chloramphenicol, 37°C, 120 rpm. We cultivated for 24 hours and stored the culture then overnight at 4°C.

...

| 55px | | | | | | | | | | |

"

"