Team:Bielefeld-Germany/Protocols/Production

From 2012.igem.org

(Difference between revisions)

KevinJarosch (Talk | contribs) (→Production) |

m (→Production) |

||

| Line 74: | Line 74: | ||

* if the purification should start the next day store the cell pellet at 4°C !(the laccase must not be frozen!) | * if the purification should start the next day store the cell pellet at 4°C !(the laccase must not be frozen!) | ||

* Resuspend the pellet in 5 mL binding buffer (His-tag affinity chromatography) for each gramm of cell paste | * Resuspend the pellet in 5 mL binding buffer (His-tag affinity chromatography) for each gramm of cell paste | ||

| + | |||

| + | <center> | ||

| + | ==Solubilization of inclusion bodies== | ||

| + | </center> | ||

| + | |||

| + | * centrifugation of the celllysate at 40,000 g for 30 minutes | ||

| + | * resuspend the pellet of the lysate in 1 mL 6M Urea solution, incubation for 1 hour | ||

| + | * centrifugation for 10 minutes at 10,000 rpm | ||

| + | * resuspend the pellet in SDS running buffer | ||

<center> | <center> | ||

Revision as of 14:33, 22 September 2012

Contents |

Production

Here all our methods according to cultivation and purification are listed.

Pre-Cultivation

Precultivation of E.Coli KRX (with or without BioBrick)

- 50 mL LB-medium, if nessassary with 20-60 mg L-1 chloramphenicol or with 100-300 mg L-1 ampicillin, in 300 mL shaking flask with baffles (Schott) with silicon plugs

- 1 mL Glycerinculture or 1 colony

- Cultivation temperature: 37 °C

- Shaking at 140 rpm

Precultivation of E.Coli Rosetta Gami 2(with or without BioBrick)

- 50 mL LB-medium with 60 mg L-1 chloramphenicol and with 300 mg L-1 ampicillin, in 300 mL shaking flask with baffles (Schott) with silicon plugs

- 1 mL Glycerinculture or 1 colony

- Cultivation temperature: 37 °C

- Shaking at 140 rpm

Precultivation of Pichia Pastoris GS115 (complex-medium)

- 50 mL YPD-medium in 300 mL shaking flask with baffles (Schott) with silicon plugs

- 1 mL Glycerinculture or 1 colony

- Cultivation temperature: 37 °C

- Shaking at 140 rpm

Precultivation of Pichia Pastoris GS115 (minimal-medium)

- 50 mL Minimal Yeast-medium in 300 mL shaking flask with baffles (Schott) with silicon plugs

- 1 mL Glycerinculture or 1 colony

- Cultivation temperature: 37 °C

- Shaking at 140 rpm

Cultivation

Expression of Laccase

- Chassis: Promega's E.Coli KRX

- Medium: Autoinduction-Medium supplemented with Chloramphenicol (final concentration 60 μg mL-1)

Cultivation with E. coli KRX in shaking flask(with baffles):

- 200 mL culture in 1000 mL shaking flask with baffles (Schott) with silicon plugs

- Cultivation temperature: 37 °C

- Autoinduction-medium with 20-60 mg L-1 chloramphenicol and if nessassary with 100-300 mg L-1 ampicillin

- Shaking at 140 rpm

- for characterizations: automatic sampling every 30 min

Bioreactor cultivations with E. coli KRX

To obtain higher amounts and concentration of proteins we cultivated and expressed in a bioreactor. It is possible to cultivate several liters and to control temperature, pH and pO_2.

- Bioreactor: Braun Biostat B Bioreactor (3L), Infors Labfors Bioreactor (3L), Bioengineering NLF22 Bioreactor (7 L),

- Autoinduction-medium with 60 mg L-1 chloramphenicol

- Culture volume: 3,0-6,0 L

- Starting OD600: 0.1 - 0.2

- Airflow: 5 NL/min

- pO2-Control: 30 % airsaturation (controlled with stirrer cascade starting with 200 rpm)

- pO2=100% calibration with 300rpm

- pH: 7.0 (controlled with 2M phosphoric acid and 2 M NaOH)

- Antifoam: BASF pluronic PE-8100

- Harvest after 12-13 h

Cell Harvesting

- Harvest cells by centrifugation at 10,000 g for 10 min at 4 °C

- if the purification should start the next day store the cell pellet at 4°C !(the laccase must not be frozen!)

- Resuspend the pellet in 5 mL binding buffer (His-tag affinity chromatography) for each gramm of cell paste

Solubilization of inclusion bodies

- centrifugation of the celllysate at 40,000 g for 30 minutes

- resuspend the pellet of the lysate in 1 mL 6M Urea solution, incubation for 1 hour

- centrifugation for 10 minutes at 10,000 rpm

- resuspend the pellet in SDS running buffer

Mechanical lysis

The method of choice to disrupt the cells depends on the amount of biomass.

Mechanical lysis of the (shaking flask) cultivation

- Sonification of the re-suspended pellet on ice

- cycle number depends on the volume of the re-suspended cells (e.g. 3 mL means 3 cycles)

- one cycle means sonification treatment for 1,5 min with Sonifier 450 by Branson, max. 50 %, cooled on ice, make sure not to heat the cells too much

Mechanical lysis of the (bio-reactor) cultivation

Cell disruption with a high-pressure homogenizer:

- high-pressure homogenisation with a Rannie Homogenizer:

- disruption of the cells by 3 cycles with cooling phases between the cycles, pressure = 1200 bar, make sure not to heat the cells too much

Purification

His-tag affinity chromatography

- For buffers see here

Syringe method

- Column: 1 mL HisTrap FF crude by GE Healthcare

- Equilibrate with binding buffer(10mL)

- Load sample onto column(max. 6 mL)

- Wash with 10 mL binding buffer

- Elute with 5 mL of elution buffer

- Collect the eluate in 1 mL fractions, the purified protein is most likely in the first or second fraction

- Re-equilibrate the column with binding buffer

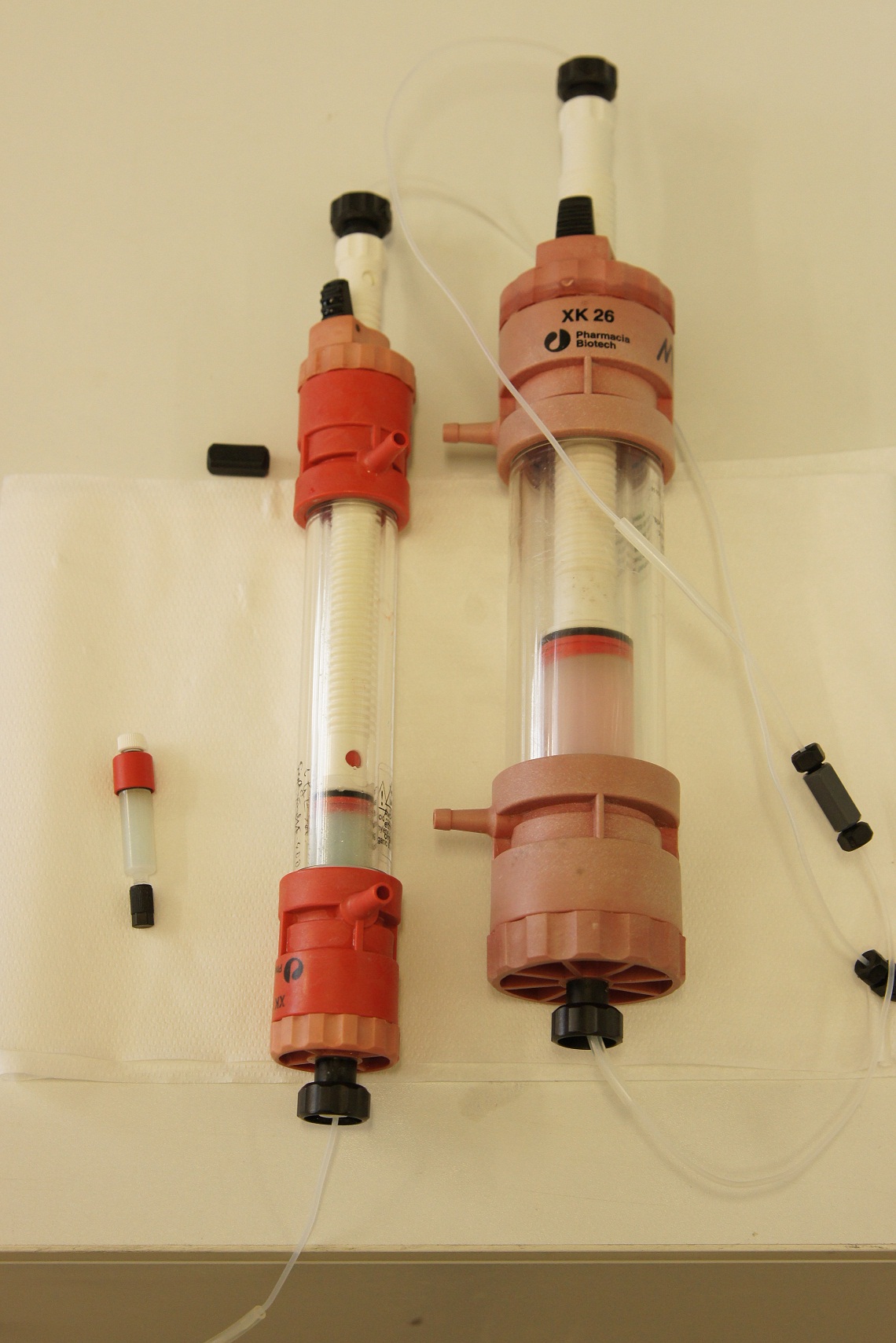

ÄKTA method

- Columns:

- 15 mL HisTrap FF crude by GE Healthcare

- 50 mL TALON-Histag-Purification Resin by Clonetech

Column preparation

- If Column is not loaded with Ni-ions /Cobalt-ions:

- Wash column with 5 - 8 Columnvolumes (CV) of deionized water

- Load column with metal-ions(4 CV)

- For HisTrap FF crude: 1,4% NiSO4-Solution

- For TALON-Histag-Purification Resin: CoCl2-Solution

Chromatography protocol for the Äkta-system

- Wash column with 10 CV of deionized water

- Equilibrate column with 10 CV of binding buffer

- Load column with supernatant of the lysed cells (Collect the Flow through for SDS-PAGE analysis)

- Wash Column with 10 CV of binding buffer (Collect the Flow through for SDS-PAGE analysis)

- Elute Protein with an increasing elutionbuffer ratio (gradient 0%-100%, length 200mL)

- Collect the eluate in 10 mL fractions

- Elute remaining proteins with 100% Elutionbuffer (4 CV)

"

"