Team:Bielefeld-Germany/Sewage treatment plant

From 2012.igem.org

Contents |

Introduction

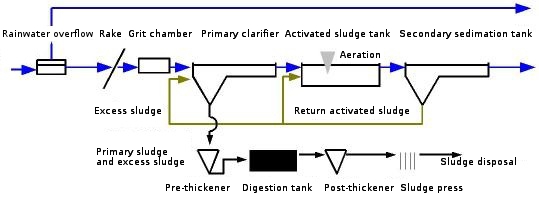

Sewage is generated every day by everyone. Therefore efficient sewage treatment is absolutely necessary to guarantee the quality of surface water, ground water and of course of drinking water. However sewage is often heterogeneous and consists of liquids from toilets, kitchen, sinks as well as liquids from industrial processes and commercial use. Sewage treatment plants have to consist of various treatment stages. The general composition of a large-scale treatment plant is shown in the flow diagram in picture 1.

Functional principle

Schematic

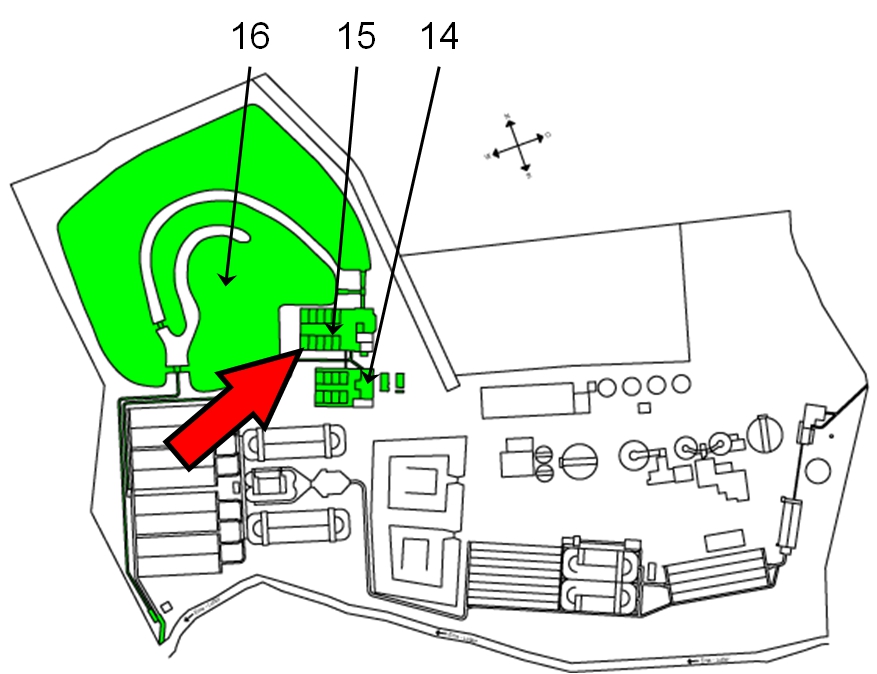

The large-scale sewage treatment plant “Obere Lutter” is located near Gütersloh and is equipped with three sewage stages. The different stages will be explained in the following section.

Primary treatment: mechanical stage

The first step in the sewage treatment ist the retaining of rude solids with rakes. Grates directly behind the rakes hinder swimming solids. The intake pumping station transports the water to the grit chamber and the primary clarifier at a slightly higher level. The grit chamber is also used to remove fat. The trapeziform cross section and aeration with air support the sedimation of sand, although the organic solid remain in the water. The sediment is removed with special movable plates and after washing and drying the sand can be used in road building. The Primary clarifier is the last step in the mechanical cleaning and works with sedimation, too. In modern sewage treatmant plants primary clarifier are rarely used because they lower the concentration of easy biodegradable sustances, which are necessary for denitrification. The mechanical stage is also called primary treatment.

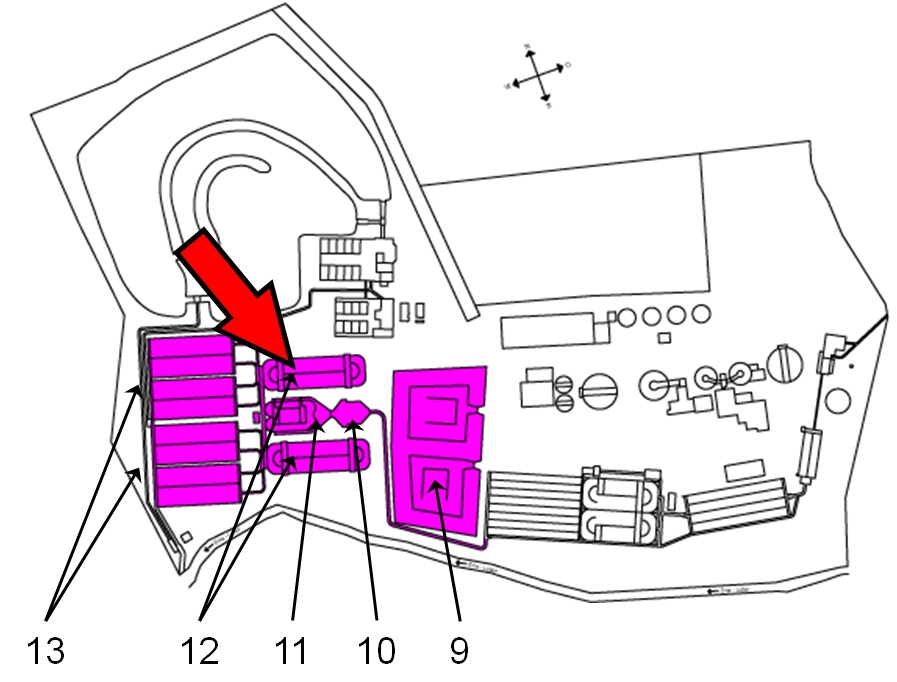

Secondary treatment: first biological stage

In the first biological stage, the so called secondary treatment, the organical content of the sewage is considerably reduced by the use of microorganisms. Most organical content are carbon, nitrogen or phosphorous compounds. Depending on tank number and design nitrification and denitrification can take place simultaneously or intermittent. The intermediate clarifier is used to remove the activated sludge with the help of return sludge pumps. For phosphorus removal chemical precipitation can be used through addition of iron salts. Also salts can be added if pH adjustment is necessary.

Secondary treatment: second biological stage

In the second biological stage compensation tanks are used to retent surplus water if the flow rate gets too large. Before the waste water is directed into another denitrification tank it gets lifted by a pump station. So the water can flow in a free gradient through the second biological stage. The second denitrification upstream to the actived sludge tank works with microorganism to further degrade nitrate compounds to elementary nitrogen. The operation procedure of the second activated sludge tank is similar to the sludge tanks used in the primary biological stage, but the tanks differ in size and flow rate. Therefore dimensions of the surface aeration are adjusted. Calcium carbonate may be added to adjust the pH.

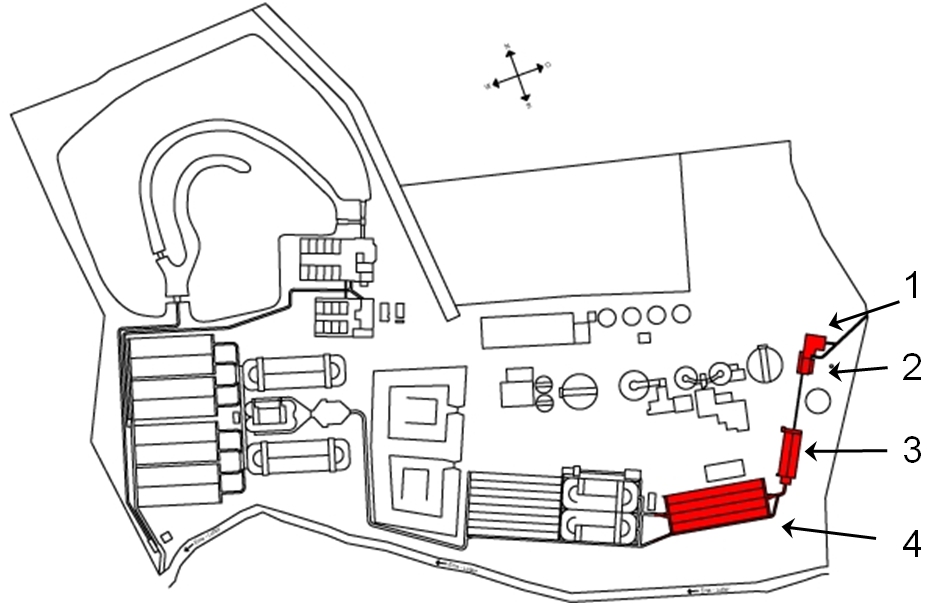

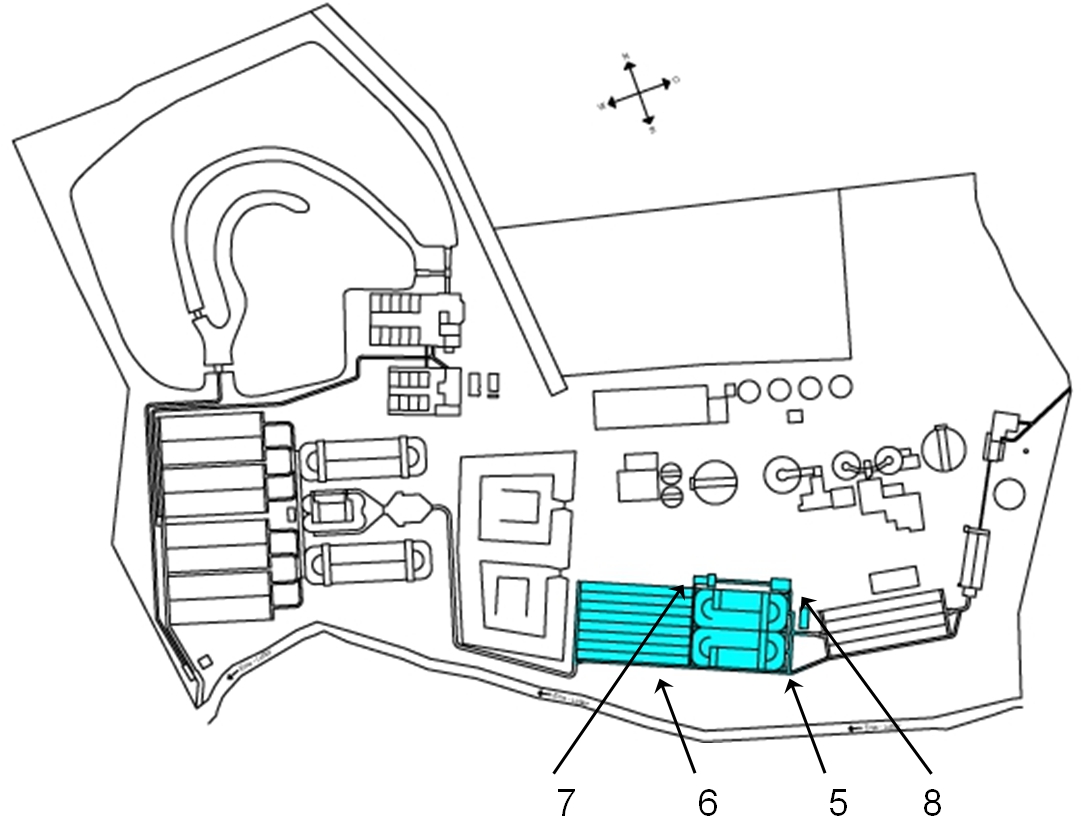

Tertiary treament: fourth purification stage

The fourth purification stage or so called tertiary treatment provides a further improvement of the effluent quality. After having passed the maturation pond the water is discharged into the environment, for example in the sea, in rivers, lakes, ground, etc.) The fixed bed dentrification lowers the concentration of nitrogen compounds with the use of biological elimination. The fixed bed works as a artificial surface for microorganisms to grow. As carbon source methanol may be added. The fixed bed consists of expanded clay, for example. Supporting flint layer provide the stability.

Floccation filtration is used to eliminate soluble phosphate based compounds. Upstream addition of iron salts causes precipitation of the phosphates as insoluble compounds. The filtration is aerated, air and wastewater flow co-current through the filter. Attached microorganisms and aeration cause nitrification, but aeration is also needed to eliminate the added methanol.

The new innovation: Immobilized Laccases

Expert evaluation

Sewage treatment plant: Schloß Holte-Stukenbrock

| 55px | | | | | | | | | | |

"

"