Team:Bielefeld-Germany/Results/halo

From 2012.igem.org

Summary

First some trials of shaking flask cultivations were made with various parameters to identify the best conditions for production of the His tagged laccase Lbh1 from [http://www.dsmz.de/catalogues/details/culture/DSM-18197.html?tx_dsmzresources_pi5 Bacillus halodurans C-125 ] named BHAL. Due to inactivity of the enzyme in the cell lysate a purification method was established (using Ni-NTA-Histag resin). BHAL could not be detected by SDS-PAGE (theoretical molecular weight of 56 kDa) or activity test by using the BioBrick <partinfo>BBa_K863020</partinfo> and E. coli KRX as expression system. Due to this results the new BioBrick <partinfo>BBa_K863022</partinfo> was constructed and expressed E. coli Rossetta-Gami 2. With this expression system the laccase could be produced and analysed via SDS-PAGE. A small scale Ni-NTA-column was used to purify the laccase. The fractionated samples were tested regarding their activity with ABTS and showed ability in oxidizing ABTS. A scale up was not yet performed.

Contents |

Cultivation, Purification and SDS-PAGE

Cultivation

The first trials to produce the Lbh1 - laccase from Bacillus Halodurans (named BHAL) were performed in shaking flasks with various flask designs (from 100 mL-1 to 1 L flasks, with and without baffles) and under several conditions. The varied parameters in our screening experiments were temperature (27 °C,30 °C and 37 °C), concentration of chloramphenicol (20-170 µg mL-1), induction strategy (autoinduction and manual induction with 0,1 % rhamnose) and cultivation time (6 to 24 h). Furthermore we cultivated with and without 0.25 mM CuCl2 to provide a sufficient amount of copper, which is needed for the active center of the laccase. E.coli KRX was not able to produce active BHAL under the screened conditions, therefore another chassis was chosen. For further cultivations E. coli Rosetta-Gami 2 was transformed with BBa_K863012, because of its ability to translate rare codons. BHAL was produced under the following conditions:

- flask design: shaking flask without baffles

- medium: LB-Medium

- antibiotics: 60 µg mL-1 chloramphenicol and 300 µg mL-1 ampicillin

- temperature: 37 °C

- cultivation time: 24 h

Just a small scale cultivation was performed so far.

Purification

The cells were harvested and resuspended in Ni-NTA-equilibrationbuffer, mechanically lysed by sonification and centrifuged. After preparing the cell paste the BHAL could not be purificate with the 15 mL column, because of its damage. For this reason a small scale purification (6 mL) of the supernatant of the lysate was made with a 1 mL Ni-NTA-column. The elution was collected in 1 mL fractions.

SDS-PAGE

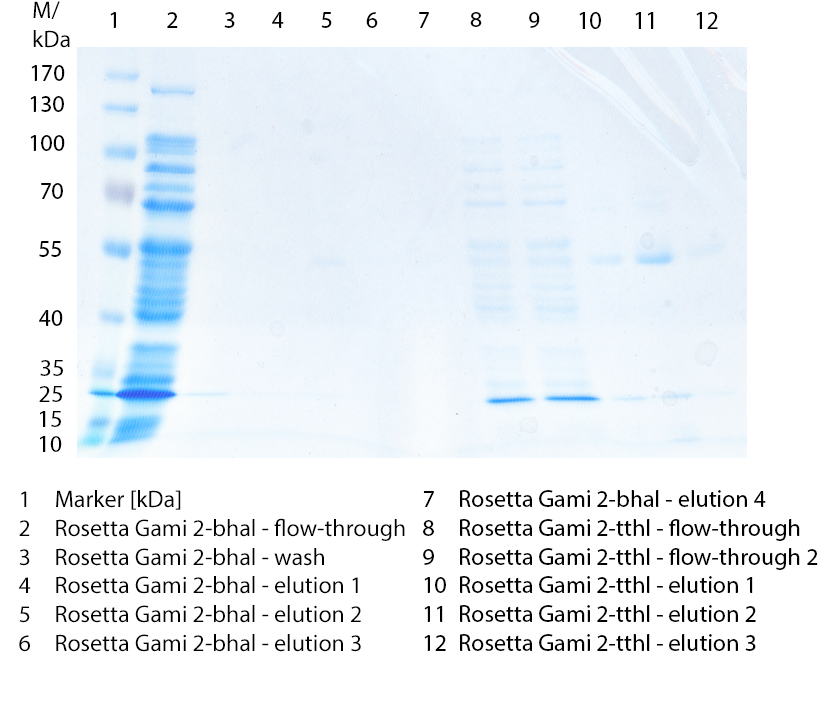

In figure 1 the different fractions of the purified cell lysate of E. coli Rosetta-Gami 2 with <partinfo>BBa_K863022</partinfo> are shown in a SDS-PAGE. BHAL has a molecular weight of 56 kDa. In lane 5, which corresponds to the elution fraction 2, a light band of 56 kDa is visible. Therefore the fractions were further analysed by activity test and MALDI-TOF.

Activity Analysis of [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863022 BHAL]

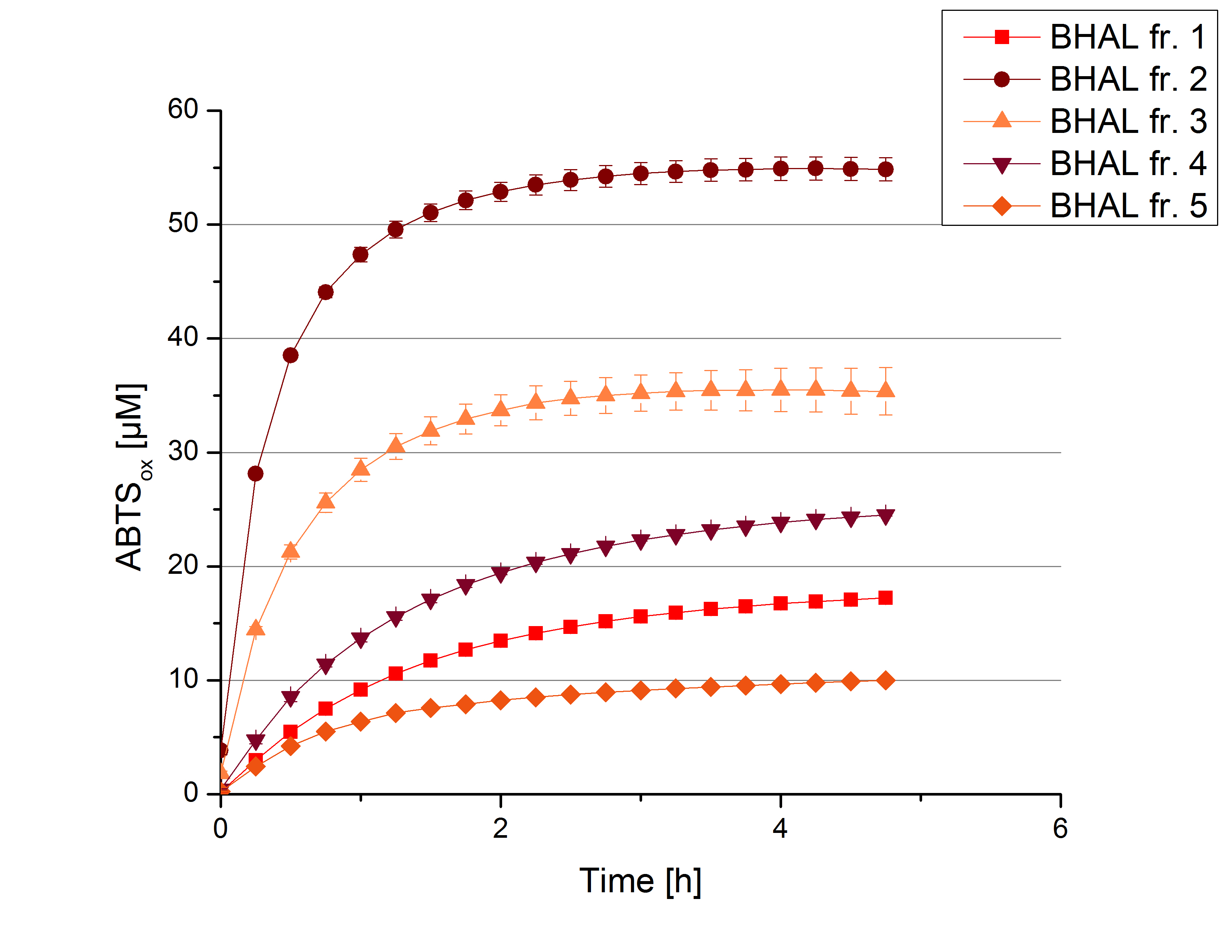

The resulting fractions of the cultivation and pruification of [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863022 BHAL] (fraction 1 to 5) were analysed with activity tests. After rebuffering into deionized H2O and icubation with 0.4 mM CuCl2 for 2 hours, the samples were measured with 100 mM sodium acetate buffer, 140 µL sample, 0.1 mM ABTS, ad 200 µL deionized H2O. The change in optical density was measured at 420 nm, reporting the oxidization of ABTS through laccases for 5 hours at 25°C. An increase in ABTSox can be seen (figure 2), indicating produced [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863022 BHAL] laccase in each fraction. Fraction 2 shows the highest amount of ABTSox (55%) after reaching its saturation after 3 hours. Compared to [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863000 BPUL] laccases [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863022 BHAL] is capable to reach a saturation after 3 hours with approximately oxidizing 55% of used ABTS. Therefore [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863022 BHAL] is a interesting laccase for the project and is going to be characterized further.

| 55px | | | | | | | | | | |

"

"