Team:Columbia-Cooper-NYC/Overview

From 2012.igem.org

(→Overview) |

MChowdhury (Talk | contribs) |

||

| Line 144: | Line 144: | ||

<div id="m7" onmouseover="mcancelclosetime()" onmouseout="mclosetime()"> | <div id="m7" onmouseover="mcancelclosetime()" onmouseout="mclosetime()"> | ||

<a href="https://2012.igem.org/Team:Columbia-Cooper-NYC/Safety">Safety</a> | <a href="https://2012.igem.org/Team:Columbia-Cooper-NYC/Safety">Safety</a> | ||

| - | |||

</div> | </div> | ||

</li> | </li> | ||

Latest revision as of 03:26, 4 October 2012

Overview

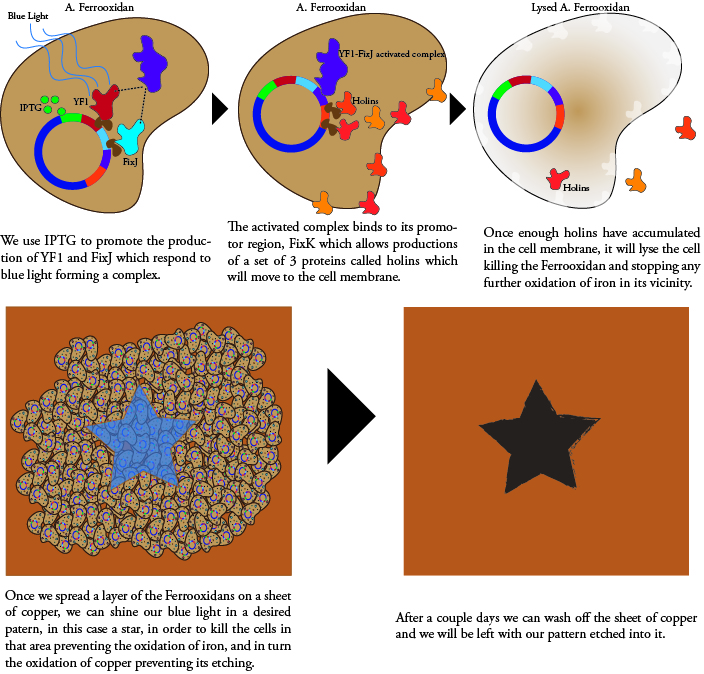

In deciding on a project to work on for iGEM, Cooper Union and Columbia University students looked for something that was both relevant in the modern world and environmentally friendly, while minimizing safety concerns regarding any proposed ideas. It was brought to the team’s attention that current electronics manufacturing processes are harmful to the environment (1). With this in mind, the team came up with a synthetic biology approach to etch copper in order to redefine the manufacturing of printed circuit boards.

While brainstorming ideas, we came across Acidithiobacillus ferrooxidans, an acidophilic prokaryote that oxidizes Fe2+ to Fe3+. The oxidized iron can then oxidize the copper. When copper is oxidized, it becomes soluble. This means that circuit boards can be printed provided the ability to exert spatial control over these chemical reactions.

The following question ensued: what would provide the ability to exert spatial control over copper oxidation on a circuit board? Light is non-intrusive, cheap, and widely available. Furthermore, light can be manipulated easily in terms of wavelength and resolution. By inserting a light-activated mechanism, the bacteria could etch in the desired pattern by turning a gene on or off.

What gene would allow controlled etching? If light activated a gene that induced cell death through lysis, the bacteria that survived would continue to etch away at the copper while the dead bacteria would stop etching. This would achieve what was desired: spatially controlled etching.

(1)Yale iGEM Team 2010 https://2010.igem.org/Team:Yale/Our_Project/Applications

"

"