Team:TU Munich/Project/Brewing

From 2012.igem.org

(→The Brewing Process) |

(→The Brewing Process) |

||

| Line 24: | Line 24: | ||

=== Preparation of the Mash === | === Preparation of the Mash === | ||

| - | '''(A)''' We start by | + | '''(A)''' We start by filling 20L water in a pot and heating it to about 50°C and then add 4-5kg of shredded malt. If you are in possession of a special bag for mash, a so called "Maischesack", you can fill the malt in the bag and hang it into the pot. Mind that the bag should not touch the bottom of the pot, as this could lead to burning of the bag and result in a slightly burned taste. |

| - | + | ||

| + | '''(B)''' We keep up the temperature of 50°C and continuously stir the mixture for 30 minutes. During these 30 minutes proteaeses will decompose proteins contained in the shredded malt. After those 30 minutes we heat the mixture to 63°C and keep up this temperature for 60 minutes. Subsequently we heat to 73°C and keep stirring continuously. | ||

| + | |||

| + | '''(C)''' The next step is the iodine test, to we verify whether starch was completely converted to sugar. We remove a small sample of mash and add iodine. A resulting blue-violet coloring indicates that there is still some leftover starch so the temperature of 73°C is kept up and this step is repeated until no staining is visible. | ||

The next step is to raise to 76 °C, after one hour the mash is ready and can be removed from the pot, and filtered. The fluid is put into the cleaned pot again and slowly heated up to 100 °C after 10 minutes the hop is added. This is now the Gyle, which boils now for about an hour. | The next step is to raise to 76 °C, after one hour the mash is ready and can be removed from the pot, and filtered. The fluid is put into the cleaned pot again and slowly heated up to 100 °C after 10 minutes the hop is added. This is now the Gyle, which boils now for about an hour. | ||

Revision as of 17:33, 25 September 2012

Brewing

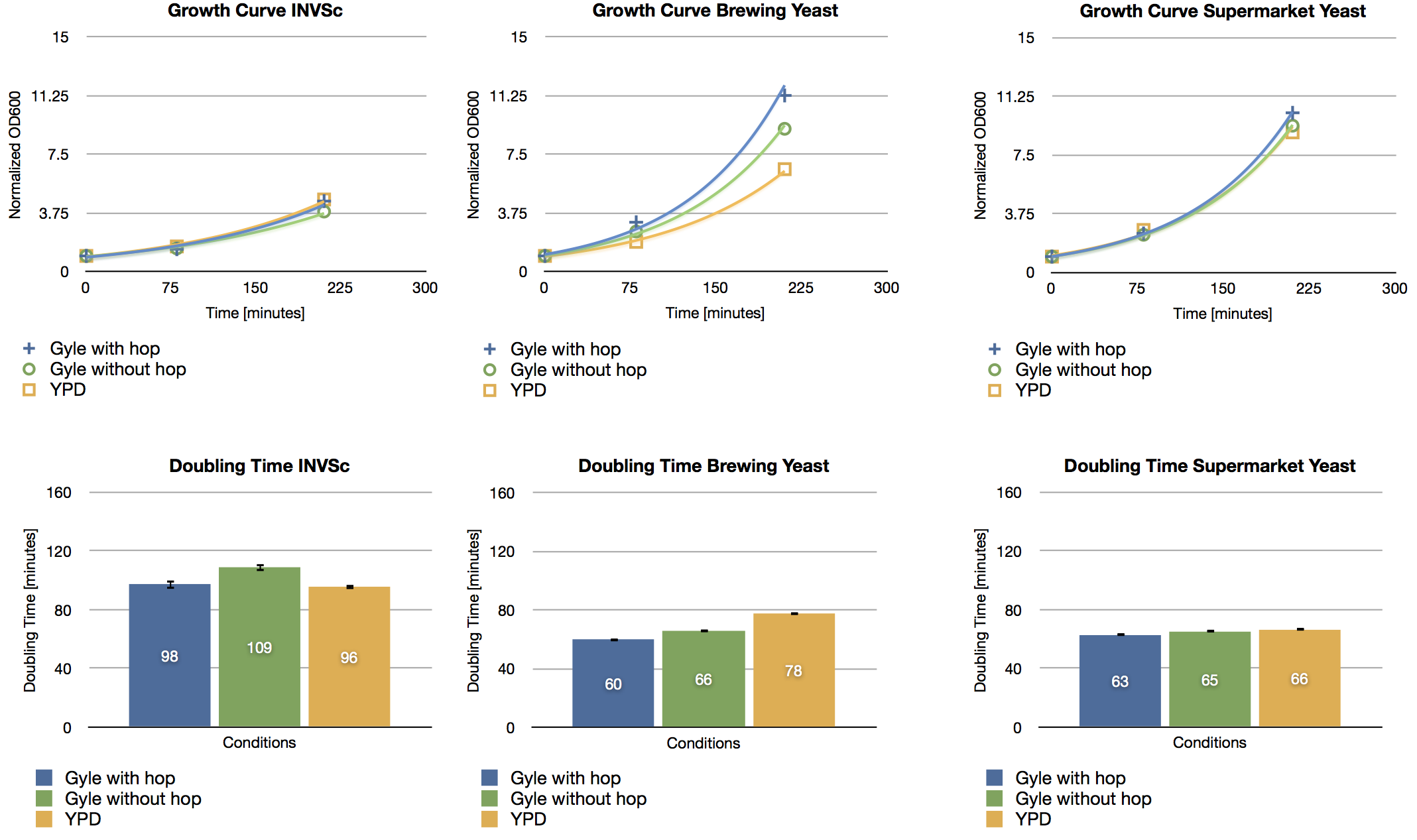

Contrary to popular opinion, the chief ingredient of beer is not YPD but gyle, a carefully prepared mixture of malt, hop, barley and water. Although the name S. cerevisiae suggests that it is used in the beer brewing process, in fact the yeast employed in brewing have strongly adapted to gyle, as they are reutilized in every succeeding brewing cycle. Hence some investigation on how our yeast performs in gyle was necessary.

Description idea.

- Does our laboratory streain of yeast survive the conditions of "the brewing-media"

- Are the substances that shall be produced by the yeast toxic and where is the toxic concentration.

- Try a brew with yeast having the expression cassetts on transient transfected vector.

- Try a brew with yeast having the expression cassetts stabely integrated in the genome.

The Brewing Process

Preparation of the Mash

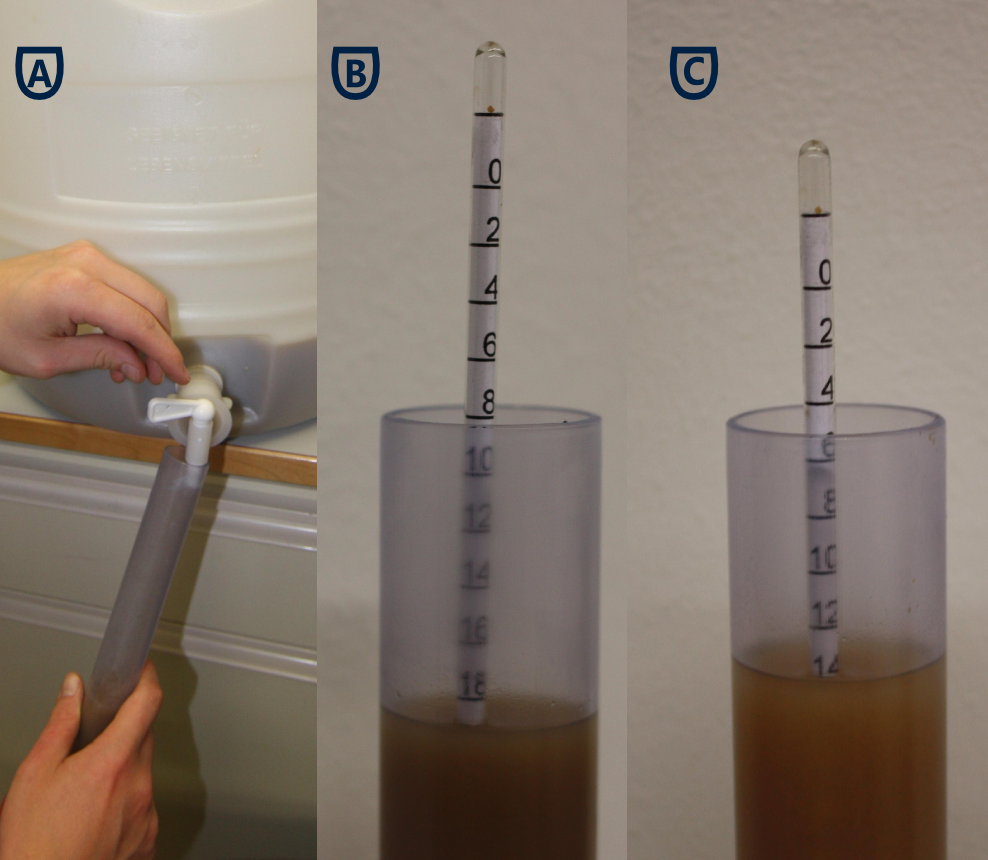

(A) We start by filling 20L water in a pot and heating it to about 50°C and then add 4-5kg of shredded malt. If you are in possession of a special bag for mash, a so called "Maischesack", you can fill the malt in the bag and hang it into the pot. Mind that the bag should not touch the bottom of the pot, as this could lead to burning of the bag and result in a slightly burned taste.

(B) We keep up the temperature of 50°C and continuously stir the mixture for 30 minutes. During these 30 minutes proteaeses will decompose proteins contained in the shredded malt. After those 30 minutes we heat the mixture to 63°C and keep up this temperature for 60 minutes. Subsequently we heat to 73°C and keep stirring continuously.

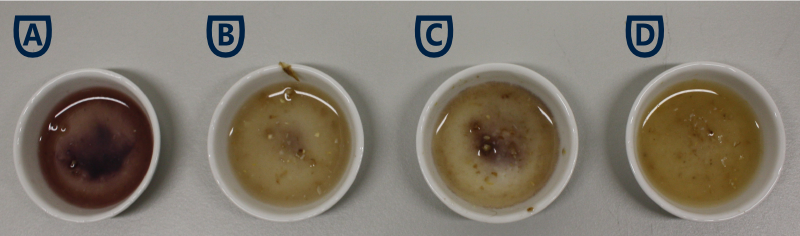

(C) The next step is the iodine test, to we verify whether starch was completely converted to sugar. We remove a small sample of mash and add iodine. A resulting blue-violet coloring indicates that there is still some leftover starch so the temperature of 73°C is kept up and this step is repeated until no staining is visible.

The next step is to raise to 76 °C, after one hour the mash is ready and can be removed from the pot, and filtered. The fluid is put into the cleaned pot again and slowly heated up to 100 °C after 10 minutes the hop is added. This is now the Gyle, which boils now for about an hour.

Next is another filtration into the final bucket, this has to be sterilized before. This bucket is closed and put into a cold room. When the temperature has fallen to 24 °Celsius or less, the yeast is added, a special covering put on the bucket (it has a hole for the CO2) and the bucket is left alone for 6 days at a temperature of 21 °C. Now the fermentation starts and the alcohol is produced by the yeast.

In the end iGEM's first and finest is finished!

Results

Experiment 1: Survival and growth of different yeast strains under various conditions

Experiment 2: Toxic concentration of the substances to be produced

Experiment 3: Experiments with expression cassetts on a transient transfected vector

Experiment 4: Expression cassetts stabely integrated in the genome

"

"