Team:UNITN-Trento/Safety

From 2012.igem.org

The Safety Questions, answered.

1. Would any of your project ideas raise safety issues in terms of: researcher safety, public safety, or environmental safety?

For the duration of our project, there was nothing that we did that raised any safety concerns for the public or environment. Nevertheless, we did work with enzymes that produce low levels of hydrogen sulfide, which is a toxic substance. Therefore, without proper precautions, there would have been a risk for us, the researchers. We took several steps, outlined below, to ensure that we always worked in a completely safe environment.

The work was performed in a modern and well equipped teaching laboratory (Biosafety Level 1). The teaching laboratory was monitored by a well trained staff of technicians that ensured the proper use of equipment and that safety rules were followed at all times. In June, we also received some training from Rossella Tomazzoli and Margherita Kos, two of them, in which they explained to us how to use the instrumentation and how to dispose of the chemical and biological waste. All of the chemical and biological waste was kept under the chemical hood in dedicated containers. Waste samples that contained bacteria were treated with bleach prior to disposal. Biological solid waste was kept in special disposable containers. The technicians regularly removed the waste from the laboratory.

The safety aspects of our work benefited from the large amount of space given to us for our work. Therefore, we were able to designate specific benches and biological and chemical hoods for specific purposes. For example, we had a reserved area for the use of ethidium bromide that included one chemical hood and one bench to run agarose gels.

Lab coats and gloves were worn all the time.

We also set an internal team rule for which no student was permitted to work alone in the laboratory.

We worked only with commonly used E.coli strains (DH5a, Novablue, BL21(DE3), NEB10b) which are non pathogenic. We never brought bacteria outside of the lab.

For some aspects of the project, we used small amounts of chemicals that required special handling (HCl, H2SO4, H2SO3, and ninhydrin). All of these chemicals were opened and used under a chemical hood. Researchers using these chemicals always wore goggles. Material safety data sheets were also present close to the chemical hoods.

2. Do any of the new BioBrick parts (or devices) that you made this year raise any safety issues?

Two of our BioBricks (BBa_K731400 and BBa_K731480) encode a Cysteine Desulfhydrase. We realized from the beginning that these parts, when induced, would produce hydrogen sulfide through the activity of the encoded enzyme. Hydrogen sulfide is a colorless gas that can be noticeably smelled by 50% of the human population at a very low concentration (0.0047 ppm). Hydrogen sulfide is flammable and poisonous.

If yes, did you document these issues in the Registry?

We have highlighted the hydrogen sulfide issues on the main page of the Parts that we submitted (BBa_K731400, BBa_K731480, BBa_K731600) and in our Wiki Results section.

How did you manage to handle the safety issue?

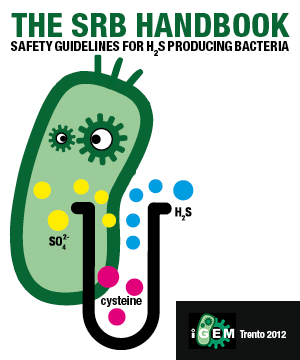

To ensure that we did not encounter problems throughout the course of our work, we consulted a chemistry professor (Graziano Guella) at the University of Trento. We also have consulted with the safety representative of the University (Marzia Filippi). Together we formulated laboratory protocols and safety guidelines for the handling of H2S. In fact, we have written a short pamphlet style document to help others work safely with hydrogen sulfide. We have posted the document in the lab notes section of our wiki page. Some of the specific steps are briefly described below.

A specific, designated chemical hood was used when bacteria producing hydrogen sulfide were used for experiments. Optical density measurements also were made under the chemical hood. A separate waste container was used to dispose of bacteria producing hydrogen sulfide. In other words, the cells were never mixed with other bacterial waste. The waste container was never filled beyond 50% volume. Ultimately, “spent” media and cultures were properly disposed.

We performed gas chromatography measurements to estimate the concentration of H2S produced with the help of Prof. Guella and a technician from the Physics department (our good friend Damiano Avi). Damiano has much experience with H2S and is an expert in gas chromatography. We estimated that the concentration of H2S that our engineered bacteria produced lower than the allowable exposure standards set by OSHA (Occupational Safety & Health Administration). You can read more about this in our results section. Nevertheless, we further sought to minimize our exposure to hydrogen sulfide by using small culture volumes and ensuring that only necessary experiments with the engineered bacteria were performed.

The goal of our work was to build a bioremediation kit for the removal of the black crust from statues and other marble lapidary. For our research, we performed the tests on small statues and pieces of marble exclusively inside of the laboratory. Nevertheless, we are confident that the use of such devices in the future in open spaces should not pose any problems to the public nor to the environment, since the small quantities of H2S produced rapidly diffuses. Non-engineered sulfate reducing bacteria, in fact, have been used in the past for similar applications on outdoor monuments without causing any hazard issues (Capitelli et al, Appl. Envirom. Microbiol. 2007). However, the method should be not applied inside internal courts of buildings, where hydrogen sulfide could be easily accumulated, thus posing a risk for the restorer.

Also, we envision the development of a portable system to clean bigger statues on site. This system could be built with two separate units: a mountable chamber built with a flexible material resistant to H2S, adaptable to the shape and size of the element to be restored, and a second chamber where H2S will be accumulated and precipitated as a metal sulfide.

How could other teams learn from your experience?

This complications posed by hydrogen sulfide is a common problem for teams or other research groups that try to engineer pathways to reduce sulfate. We believe that work with such bacteria or enzymes can be done without creating harm to the workers, the public, or the environment by following standard laboratory guidelines, posing attention to small details that make the work easier and cleaner. To help future teams we wrote a pamphlet style document for the safe handling of H2S producing bacteria. We will make this handbook available in the H2S Section of our Lab Notes. In addition, we have posted the H2S MSDS, so that's easily accessible by everyone.

3. Is there a local biosafety group, committee, or review board at your institution? If yes, what does your local biosafety group think about your project?

The University of Trento has a dedicated office for the Prevention and Protection of workers that has as part of its responsibility the care of biosafety within the University. We spoke with Dr. Marzia Filippi, who is in charge of the biosafety division. She went through the protocols that we developed with a Faculty of the Chemistry department and gave suggestions on a few key points of the protocol.

When we decided to write a brief handout for the use of H2S producing bacteria, we asked for her help in revising the manual. She was extremely helpful and happy to collaborate with us on this topic.

We feel that by explicitly spelling out rules for the handling of H2S and H2S producing bacteria, and by developing the rules with chemistry and safety experts, ensured that our work would proceed in a safe manner. A copy of the document will be deposited by Dr. Marzia Filippi into the University’s safety protocol data bank for future use.

We also spoke with Dr. Matteo Grott, who is in charge of the safety of the teaching labs. He often stopped by the lab during the summer and verified that we had no safety issues and that everything was running according to the safety rules of the University.

4. Do you have any other ideas how to deal with safety issues that could be useful for future iGEM competitions? How could parts, devices and systems be made even safer through biosafety engineering?

It would be helpful to have a short mandatory biosafety training course to be taken online by each team member through the iGEM website prior to starting the projects.

Also, if other teams start creating their own safety protocols for specific topics on their wiki pages it would be helpful, too (e.g. documents similar to our H2S producing bacteria handling document). The safety protocols could be also reviewed by iGEM HQ and added to the Registry, so that everybody could easily find them.

We think it would be wise for the Registry to have direct links from each biological Part page to its safety information and protocols. In this way, those that are interested in using a specific biological Part are immediately made aware of the safety issues, if there are any. Contributors would then be required to provide safety information for each biological Part submitted.

"

"