Team:TU Darmstadt/Project/Material Science

From 2012.igem.org

(→Material Science) |

|||

| (26 intermediate revisions not shown) | |||

| Line 25: | Line 25: | ||

<li><a href="/Team:TU_Darmstadt/Protocols" title="Protocols">Protocols</a></li> | <li><a href="/Team:TU_Darmstadt/Protocols" title="Protocols">Protocols</a></li> | ||

<li><a href="/Team:TU_Darmstadt/Materials" title="Materials">Materials</a></li> | <li><a href="/Team:TU_Darmstadt/Materials" title="Materials">Materials</a></li> | ||

| - | <li><a href="/Team:TU_Darmstadt/ | + | <li><a href="/Team:TU_Darmstadt/Modeling" title="Modeling">Modeling</a></li> |

<li><a href="/Team:TU_Darmstadt/Safety" title="Safety">Safety</a></li> | <li><a href="/Team:TU_Darmstadt/Safety" title="Safety">Safety</a></li> | ||

<li><a href="/Team:TU_Darmstadt/Downloads" title="Downloads">Downloads</a></li></ul></li> | <li><a href="/Team:TU_Darmstadt/Downloads" title="Downloads">Downloads</a></li></ul></li> | ||

| - | <li><a href="/Team:TU_Darmstadt/Human_Practice" title="Human Practice">Human Practice</a | + | <li><a href="/Team:TU_Darmstadt/Human_Practice" title="Human Practice">Human Practice</a></li> |

| - | + | ||

| - | + | ||

| - | + | ||

<li><a href="/Team:TU_Darmstadt/Sponsors" title="Sponsors">Sponsors</a><ul> | <li><a href="/Team:TU_Darmstadt/Sponsors" title="Sponsors">Sponsors</a><ul> | ||

<li><a href="/Team:TU_Darmstadt/Sponsors" title="Sponsors">Overview</a></li> | <li><a href="/Team:TU_Darmstadt/Sponsors" title="Sponsors">Overview</a></li> | ||

| Line 40: | Line 37: | ||

<!-- end #menu --> | <!-- end #menu --> | ||

</html> | </html> | ||

| - | |||

== Material Science == | == Material Science == | ||

| + | The [https://2012.igem.org/Team:TU_Darmstadt/Team#Material_Science material science group] main focus is the synthesis of [http://en.wikipedia.org/wiki/Polyethylene_terephthalate polyethylene terephthalate] ([http://en.wikipedia.org/wiki/Polyethylene_terephthalate PET]) and structural analoga for the study of the [https://2012.igem.org/Team:TU_Darmstadt/Project/Degradation degradation] mechanism. To accomplish this challenging task we work with a spectra of methods ranging from organic synthesis to atomic force microscopy. The interaction of the synthetic ([http://en.wikipedia.org/wiki/Polyethylene_terephthalate PET]) and the biological polymer (enzyme) was a matter of particular interests. | ||

| + | |||

| + | Our group is the intermediator between the theoretic [https://2012.igem.org/Team:TU_Darmstadt/Project/Simulation simulation] and applied [https://2012.igem.org/Team:TU_Darmstadt/Project/Degradation degradation] group. With our investigation of surface interactions of the degradation enzymes on different surface structures of PET we are able to supply data to both teams. Using [http://en.wikipedia.org/wiki/Atomic_force_microscopy atomic force microscopy] (AFM) the [https://2012.igem.org/Team:TU_Darmstadt/Labjournal/Material_Science resulting data] we provide, will contain information about the enzymes activity and how the degradation mechanism depends on different PET modifications. This [https://2012.igem.org/Team:TU_Darmstadt/Labjournal/Material_Science data] is essential feedback to both the simulation and degradation department for it poses a chance to verify the [https://2012.igem.org/Team:TU_Darmstadt/Modeling simulated models] and the choice of enzyme for [https://2012.igem.org/Team:TU_Darmstadt/Project/Degradation PET degradation]. | ||

| + | |||

| + | [[File:Material_science_project.png|850px]] | ||

| + | |||

| + | Due to the crystalline nature of [http://en.wikipedia.org/wiki/Polyethylene_terephthalate PET] a huge variety of PET structures with different characteristics may exist. We try to explain how the crystallinity, the surface character of the PET and the additives (crystal nucleus, plasticizers) effect the degradation process. | ||

| + | |||

| + | First we characterize the PET with light microscope detection. For exact analysis of different PET modifications it is necessary to know their specific compositions. Therefore our group will synthesise pure PET and serveral analogs. The analogs are used for characterizing the enzyme function and kinetics with UV-VIS-detection. | ||

| + | |||

| + | With diparanitrophenyl succinate and paranitrophenyl dihydrocinnamate we successfully synthesized two PET analoga. These were degraded by the [https://2012.igem.org/Team:TU_Darmstadt/Project/Degradation degradation team] using [http://partsregistry.org/wiki/index.php?title=Part:BBa_K808026 pNB-Est13]<sup>[https://2012.igem.org/Team:TU_Darmstadt/Labjournal/Degradation#CW38]</sup>. Furthermore we could demonstrate enzymatic activity on PET surfaces using atomic force microscopy<sup>[https://2012.igem.org/Team:TU_Darmstadt/Labjournal/Material_Science#Surface_analysis_of_polyethylene_terephthalate_with_atomic_force_microscopy_.28AFM.29]</sup>. | ||

| - | continue to [https://2012.igem.org/Team:TU_Darmstadt/Project/Simulation 5. Simulation] | + | Check out or labbook for the details: [https://2012.igem.org/Team:TU_Darmstadt/Labjournal/Material_Science Labjournal Material Science] or continue to section [https://2012.igem.org/Team:TU_Darmstadt/Project/Simulation 5. Simulation]. <!--for more details about our [https://2012.igem.org/Main_Page iGEM] contribution.--> |

Latest revision as of 01:42, 27 September 2012

Material Science

The material science group main focus is the synthesis of [http://en.wikipedia.org/wiki/Polyethylene_terephthalate polyethylene terephthalate] ([http://en.wikipedia.org/wiki/Polyethylene_terephthalate PET]) and structural analoga for the study of the degradation mechanism. To accomplish this challenging task we work with a spectra of methods ranging from organic synthesis to atomic force microscopy. The interaction of the synthetic ([http://en.wikipedia.org/wiki/Polyethylene_terephthalate PET]) and the biological polymer (enzyme) was a matter of particular interests.

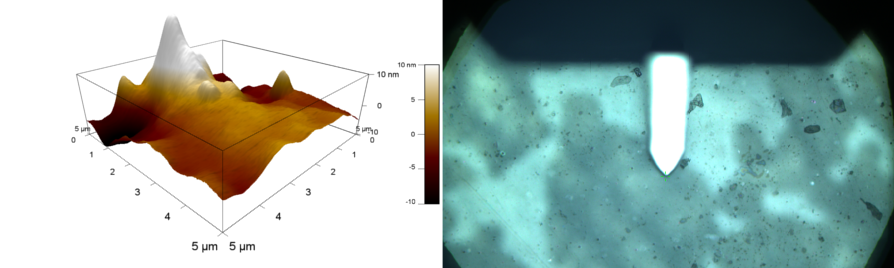

Our group is the intermediator between the theoretic simulation and applied degradation group. With our investigation of surface interactions of the degradation enzymes on different surface structures of PET we are able to supply data to both teams. Using [http://en.wikipedia.org/wiki/Atomic_force_microscopy atomic force microscopy] (AFM) the resulting data we provide, will contain information about the enzymes activity and how the degradation mechanism depends on different PET modifications. This data is essential feedback to both the simulation and degradation department for it poses a chance to verify the simulated models and the choice of enzyme for PET degradation.

Due to the crystalline nature of [http://en.wikipedia.org/wiki/Polyethylene_terephthalate PET] a huge variety of PET structures with different characteristics may exist. We try to explain how the crystallinity, the surface character of the PET and the additives (crystal nucleus, plasticizers) effect the degradation process.

First we characterize the PET with light microscope detection. For exact analysis of different PET modifications it is necessary to know their specific compositions. Therefore our group will synthesise pure PET and serveral analogs. The analogs are used for characterizing the enzyme function and kinetics with UV-VIS-detection.

With diparanitrophenyl succinate and paranitrophenyl dihydrocinnamate we successfully synthesized two PET analoga. These were degraded by the degradation team using [http://partsregistry.org/wiki/index.php?title=Part:BBa_K808026 pNB-Est13][1]. Furthermore we could demonstrate enzymatic activity on PET surfaces using atomic force microscopy[2].

Check out or labbook for the details: Labjournal Material Science or continue to section 5. Simulation.

"

"