- Would any of your project ideas raise safety issues in terms of:

- researcher safety,

- public safety, or

- environmental safety?

To answer this question, we thought about how the different elements we use in our experiments could be dangerous separately or together.

The bacteria we use for all of our cloning steps are E.Coli DH5α (originally developed by Prof. Douglas Hanahan, currently head of the Cancer Research Institute at EPFL). They derive from the K-12 E.Coli strain, which has been improved over the years to yield a high number of non-mutated and non-degraded foreign plasmids, but also to stop being virulent. They are no longer able to attach to the human gut and to infect it or form biofilms because they have lost the fimbriae that allowed them to do so. They are classed as safety level 1 according to the WHO.

The mammalian cells we use are CHO (Chinese Hamster Ovary) DG44 cells. Even though this is an “immortalized” cell line, it is established and proven not to be dangerous. Even if the researcher had a cut on his skin which came in contact with the CHO cells, an enormous amount of these would be required for any inoculation potential.

The genes we use work as light-sensitive switches (LovTAP-VP16 and melanopsin) that initiate the transcription of a readout protein. LovTAP is an artificial construct (its Lov domainhas been originally isolated from Avenasativa, the common oat). The melanopsin switch we received from Prof. Martin Fussenegger (ETHZ) is human. The other constructs we work with are readouts (quantifiable common proteins such as dsRed, GFP, SEAP, TNFR…) and the NFAT response element. None of these are hormones, oncogenes, or cytokines. They also have no known toxicity.

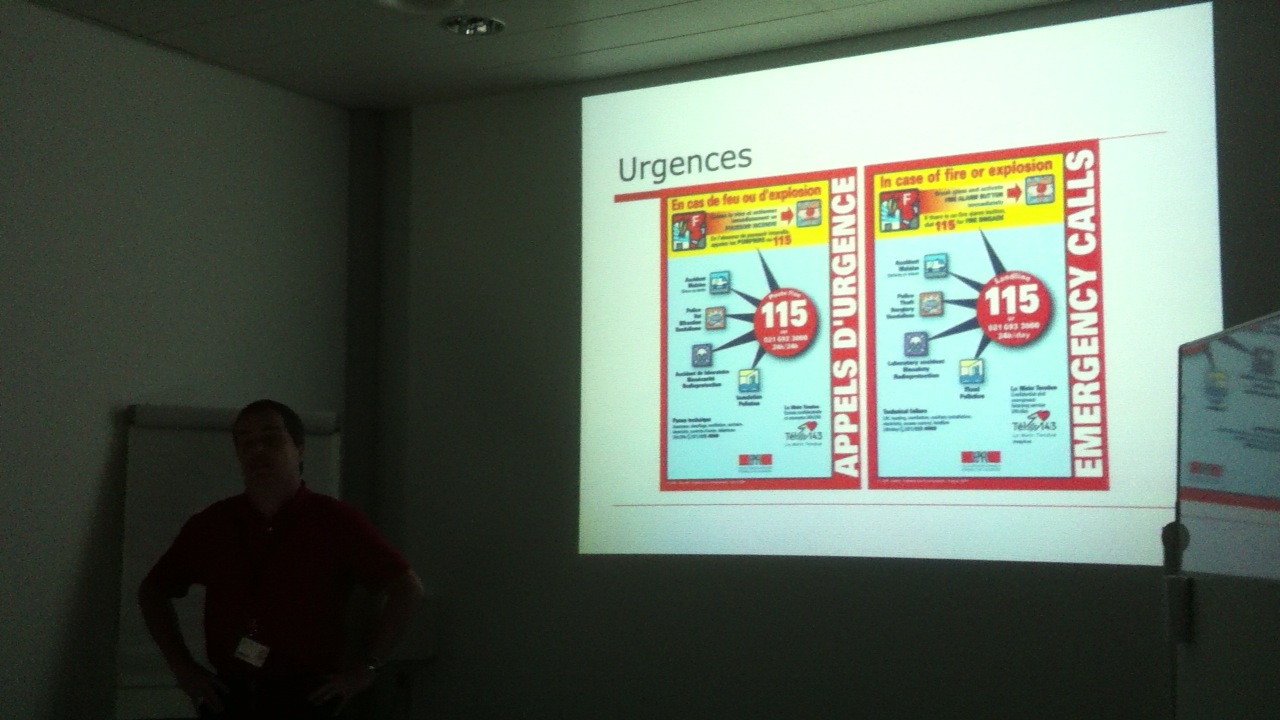

Every team member has taken the Laboratory Safety Course of EPFL, taught by Dr. Stéphane Karlen, and is aware of the potential dangers of laboratory work.

All of the above considerations lead us to the conclusion that researcher risks are minimal. They never exceed safety level 1.

Public safety risks are non-existent, as the genetically modified cells we use would be unable to survive outside of their favourite conditions in a laboratory environment, and as none of the organisms or parts in our experiments are virulent or contagious.

Environmental risks are being taken care of by inactivating and eliminating all of the genetically modified biowaste in accordance with the EPFL guidelines. Such risks are thus also non-existent.

- Do any of the new BioBrick parts (or devices) that you made this year raise any safety issues? If yes,

- did you document these issues in the Registry?

- how did you manage to handle the safety issue?

- How could other teams learn from your experience?

Please refer to question one for more details on the genetic constructs we use. The BioBrick we have the most interest in is LovTAP-VP16. It is a modified version of the protein that has been submitted as a BioBrick in 2009 by the EPFL team. It is now fused to a VP16 domain to allow mammalian expression. Neither the existing protein, neither the changes it has undergone can lead to any known risks. This is a simple system and the DNA binding is controlled by light.

The other BioBricks we submit this year do not raise any safety issues either.

- Is there a local biosafety group, committee, or review board at your institution?

- If yes, what does your local biosafety group think about your project?

- If no, which specific biosafety rules or guidelines do you have to consider in your country?

There is one. We have had a meeting with Dr. Stéphane Karlen, who is the Biosafety Coordinator at EPFL. He has kindly agreed to conduct an assessment of our project.

According to his analysis, no elements of risk group 2 or higher have been identified. The project always remains at a security level one.

The laboratory we mostly work in (LBTC, Prof. Florian Wurm’s group) adheres to the EPFL biosafety requirements, including the management of genetically modified waste (chemical and autoclave). The laboratories are correctly equipped.

Given the above, we can affirm that our project and our working environment respect all of the Swiss biosafety and biosecurity laws and guidelines.

- Do you have any other ideas how to deal with safety issues that could be useful for future iGEM competitions? How could parts, devices and systems be made even safer through biosafety engineering?

Every new iGEM team should be informed about safety issues and guidelines. The basics of secure lab work should be taught to them. The risks are minimized when everyone is aware of the potential dangers of what they are doing, and is prepared to deal with them accordingly.

In our case, depending on the readout protein we use with the LovTAP-VP16 switch, leakage might need to be minimized in order not to waste precious therapeutic proteins and to avoid possible toxic effects on the producing cells. In order to prevent expression without light, we might imagine another “safety switch” that would make sure no protein is produced in the dark state through a feedback loop.

Such biological double checks and controls might be useful in any iGEM project that might involve production of a risky protein.

Safety class 06.06.2012

"

"