Team:Bielefeld-Germany/Results/thermo

From 2012.igem.org

Summary

First some trials of shaking flask cultivations were made with different parameters to define the best conditions for production of the His tagged laccase Ltth from [http://www.dsmz.de/catalogues/details/culture/DSM-7039.html?tx_dsmzreso Thermus thermophilus HB27] named TTHL. Due to inactivity of the enzyme in the cell lysate a purification method was established (using Ni-NTA-His tag resin). Using E. coli KRX containing BioBrick <partinfo>BBa_K863010</partinfo> TTHL could not be detected by SDS-PAGE (molecular weight of 53 kDa) or by activity test. Therefore a new BioBrick <partinfo>BBa_K863012</partinfo> was constructed and expressed in E. coli Rosetta-Gami 2. With this expression system the TTHL could be detected by SDS-PAGE (molecular weight of 53 kDa). It was purified by using a small scale Ni-NTA column. The fractionated samples were tested regarding their activity. Activity in oxidizing ABTS has been detected. After measuring activity of TTHL a scale up was successfully implemented up until 6 L.

Contents |

Cultivation, Purification and SDS-PAGE

Shaking Flask Cultivation

The first trials to produce the Ltth-laccase from [http://www.dsmz.de/catalogues/details/culture/DSM-7039.html?tx_dsmzresources_pi5 Thermo thermophilus HB27] (named TTHL) were performed in shaking flasks with various volumes (from 100 mL to 1 L flasks, with and without baffles) and under different conditions. The used BioBrick was <partinfo>BBa_K863010</partinfo> expressed in E. coli KRX. The screened parameters during the experiments were temperature (27 °C, 30 °C and 37 °C), concentration of chloramphenicol (20-170 µg mL-1), induction strategy (autoinduction and manual induction with 0.1 % rhamnose) and cultivation time (6 to 24 h). Furthermore, E. coliwas cultivated with and without 0.25 mM CuCl2 to provide a sufficient amount of copper, which is needed for the active center of the laccase. Under the screened conditions it could not be shown that E. coli KRX produces active TTHL. Therefore another BioBrick was constructed and another chassi was chosen. For further cultivations the BioBrick <partinfo>BBa_K863012</partinfo> was used, which has a constitutive promoter instead of the T7 promoter system. Additionally, the strain E. coli Rosetta-Gami 2 was chosen, because of its ability to translate rare codons. TTHL was then produced under the following conditions:

- flask design: shaking flask without baffles

- medium: LB-Medium

- antibiotics: 60 µg mL-1 chloramphenicol and 300 µg mL-1 ampicillin

- temperature: 37 °C

- cultivation time: 24 h

The reproducibility of the measured data and results were investigated for the shaking flask cultivation, but not yet for the bioreactor cultivation.

Fermentation of E. coli KRX with <partinfo>BBa_K863012</partinfo>

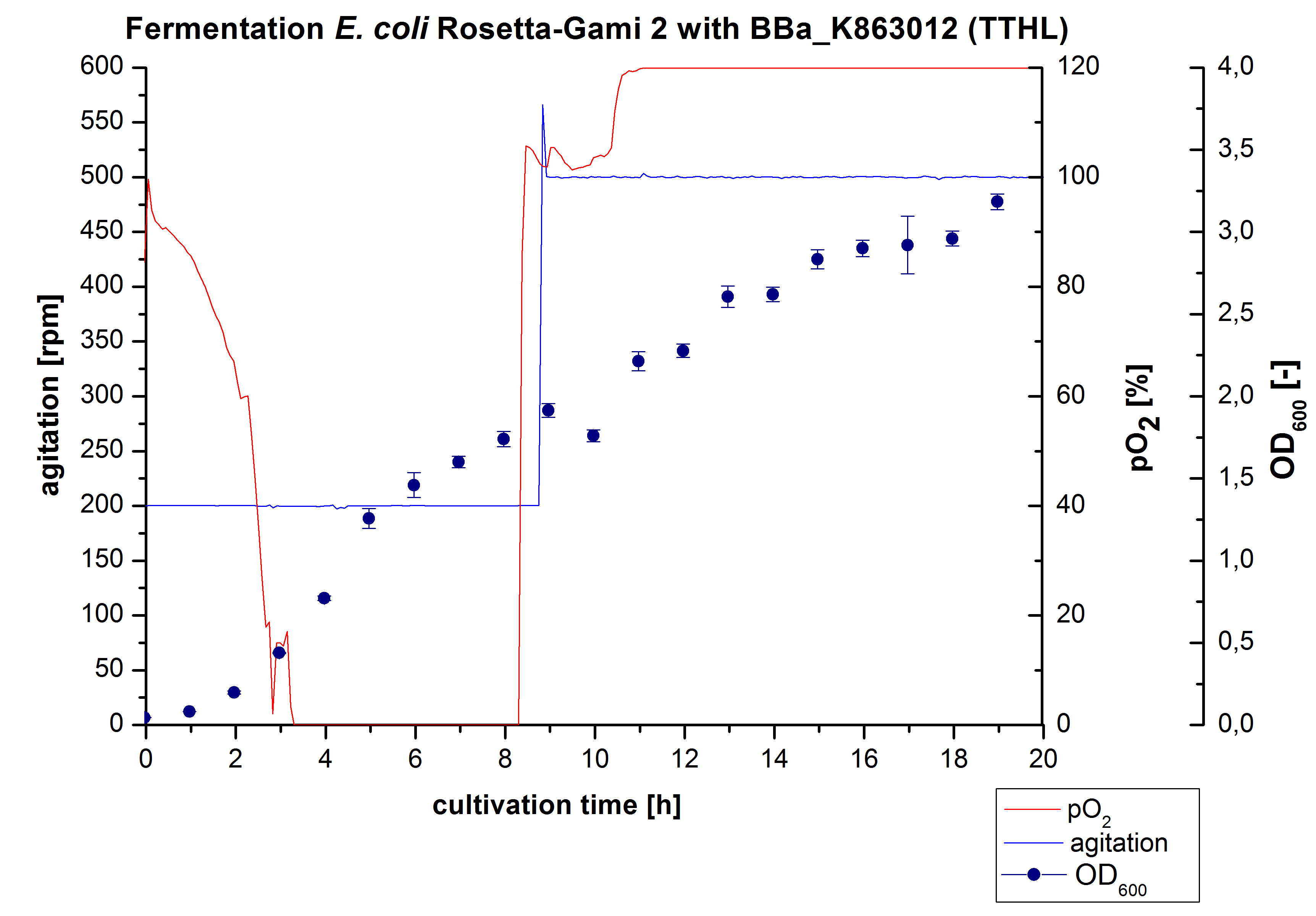

After measuring activity of TTHL we made a scale-up and fermented E. coli Rosetta-Gami 2 with <partinfo>BBa_K863000</partinfo> in a Bioengineering NFL22 with a total volume of 6 L. Agitation speed, pO2 and OD600 were monitored and are illustrated in Figure 1. There is no noticeable lag phase. Due to the cell growth the pO2 decreased to a value of 0 %, which was additionally caused by the breakdown of the control unit. After a cultivation time of 9 hours the agitation speed was increased manually up to 500 rpm, which resulted in a higher pO2 value of more than 100 % for the rest of the cultivation. During the whole process the OD600 increased slower when compared to the fermentation of E. coli KRX with <partinfo>BBa_K863000</partinfo> or <partinfo>BBa_K863005</partinfo>. The maximal OD600 was reached after 19 hours of cultivation time at which point the cells were harvested.

Purification of TTHL

The cells were harvested and resuspended in Ni-NTA-equilibrationbuffer, mechanically lysed by homogenization and centrifuged. After preparing the cell paste the TTHL could not be purificate with the 15 mL column, due to a defect. For this reason a small scale purification (6 mL) of the supernatant of the lysate was made with a 1 mL Ni-NTA-column.

SDS-PAGE of TTHL purification

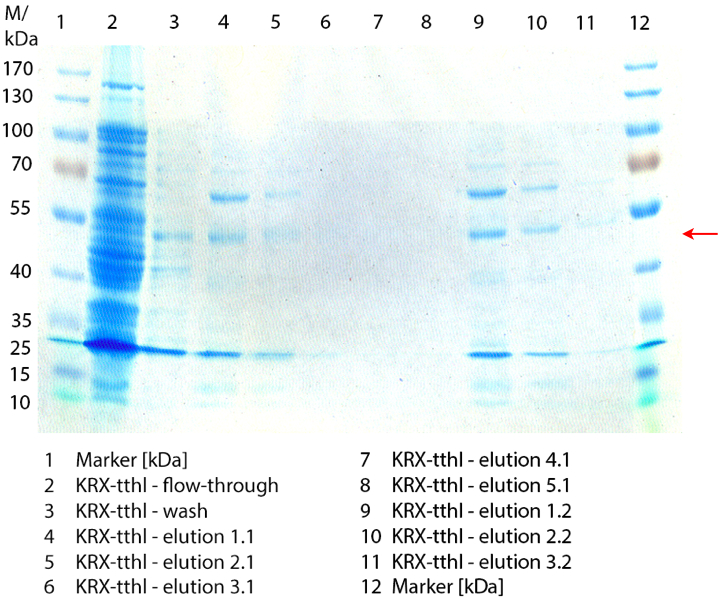

Figure 2 shows the SDS-PAGE of the purified E. coli Rosetta-Gami 2 lysates fermented in 6 L Bioengineering NFL22 including the flow-through, wash and all elution fractions (1 to 5). TTHL has a molecular weight of 53 kDa and the corresponding band was marked with a red arrow. The TTHL band appears in fractions 1 to 3, but not in the other two elution fractions. Furthermore there are some other non-specific bands, which could not be identified. To improve the purification the 15 mL column an ÄKTA method could be implemented.

Activity analysis of [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863012 TTHL]

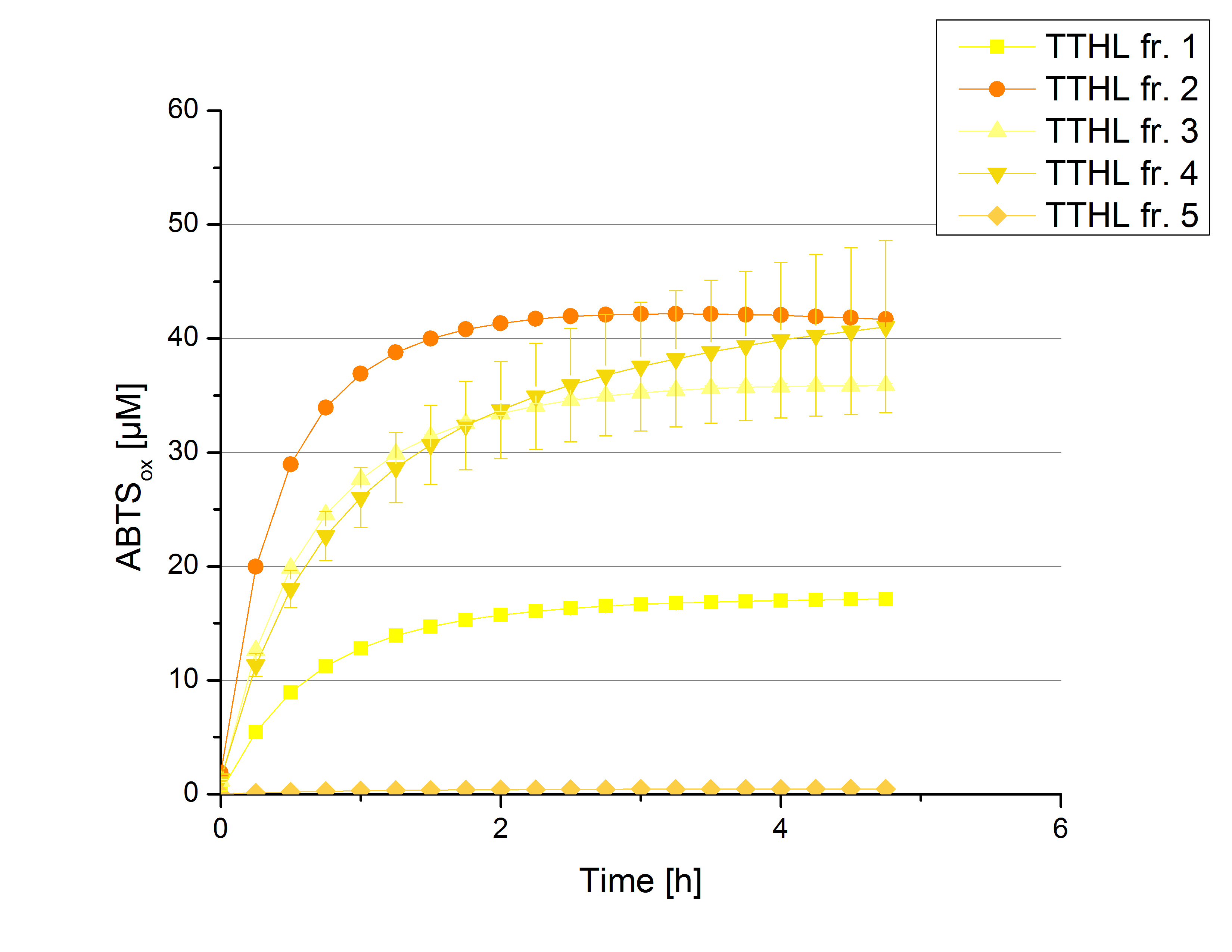

There was no activity measurable after cultivation and purification of [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863010 TTHL] under the control of a T7 promoter. Activity tests of [http://partsregistry.org/wiki/index.php?title=Part:BBa_K863012 TTHL] under a constitutive promoter did reveal TTHL laccases capable of oxidizing ABTS. Fractions 1 to 5 of the purification above were rebuffered with deionized H2O and incubated with 0.4 mM CuCl2 for 2 hours. Activity measurements were performed using 100 mM sodium acetate buffer, 140 µL sample, 0.1 mM ABTS, ad 200 µL deionized H2O. The change in optical density at 420 nm was detected, reporting the oxidization of ABTS through laccases. Fractions 2 to 5 show activity (Figure 3). Fraction 2 seems to contain most of TTHL showing the highest activity compared to the other fractions: 40% of the used ABTS has been oxidized after 2 hours. Based on these results protein concentrations have to be determined and the activity of the TTHL laccase can be characterized in further experiments including pH optimum and activity in regard of temperature shifts.

| 55px | | | | | | | | | | |

"

"