Team:Bielefeld-Germany/Protocols/Analytics

From 2012.igem.org

Sodium dodecyl sulfate polyacrylamide gel electrophoresis (SDS-PAGE)

This analytical method can be used for separation and identification of proteins according to their electrophoretic mobility. The mobility is a function of length of the molecular weight. Proteins that have identical charge per unit mass due to binding of SDS results in an equal electrophoretic mobility.

Pouring the polyacrylamide gel

- Make a master mix for the stacking and separating gel without adding ammonium persulfate and TEMED.

- Aliquote 6,5 mL for each separating and 2,5 mL for each stacking gel.

- Add ammonium persulfate and TEMED to each separating gel aliquote and pour the solution quickly into your gel casting form. Leave about 2 centimeters below the bottom of the comb for the stacking gel.

- Layer isopropanol on top of the gel.

- Leave the separating gel at room temperature for >60 minutes to polymerize.

- Remove isopropanol and wait until the surface is dry.

- Add ammonium persulfate and TEMED to each separating gel aliquote and pour the solution quickly into your gel casting form.

- Insert comb without getting bubbles stuck underneath

- Leave the gel at room temperature for >60 minutes to polymerize.

- For storage

- Remove sealing and store the gel wrapped in moistened paper towel at 4°C.

Preparing the sample

- Mix your protein mixture 4:1 with Laemmli-buffer (15 µL protein solution + 5 µL Laemmli-buffer)

- Heat for 5 minutes at 95 °C.

Running the gel

- Remove sealing, put the polymerized gel into gel box and pour SDS running buffer into the negative and positive electrode chamber.

- Remove comp without destroying the gel pocket.

- Pipet the sample into the gel pockets, adjusting the volume according to the amount of protein in your sample. Make sure to include a lane with molecular weight standards (5µl PageRuler Prestained Protein Ladder™ (Fa. Fermentas)) to determinate the molecular weight of your sample.

- Connect the power lead and run the stacking gel with 10 mA until the blue dye front enters the separating gel.

- Raise amperage up to 20 mA for running the separating gel.

- When the distance of the lowest molecular weight standard lane to the gel end is down to 0.5 cm stop the electrophoresis by turning off the power supply.

Fairbanks Coomassie staining

Modiefid steining protocol from [http://www.ncbi.nlm.nih.gov/pmc/articles/PMC1161216/pdf/biochemj00457-0254.pdf Fairbanks et al., (1971)].

- After finishing the SDS-PAGE remove gel from gel casting form and tranfer it in to a box with 100 mL of solution A.

- Heat the gel in a microwave for 2 min at 600 W.

- Shake the gel for 5-10 minutes.

- Remove solution A and wash the gel with dH2O.

- Add 100 mL of solution B and heat the gel in a microwave for 2 min at 600 W.

- Shake the gel for 5-10 minutes.

- Remove solution B and wash the gel with dH2O.

- Add 100 mL of solution C and heat the gel in a microwave for 2 min at 600 W.

- Shake the gel for 5-10 minutes.

- Remove solution C and wash the gel with dH2O.

- For bleaching the background add 100 mL of solution D and heat the gel in a microwave for 2 min at 600 W.

- Shake the gel for 5-10 minutes.

- Remove solution D and wash the gel with dH2O. If necessary repeat the last 3 steps with solution D.

Spectrofluorophotometer

This Methode was used to detect the absorption of the degradation product. Since we dont't know anything about what thoose producs are, we decided to measure the excitation/ emission from them.

We measured the UV- excitation/ emission from the following degradation products: Estradiol, Estrone, Ethin estradiol and to detect Diclofenac Extinction/ Emission values since we couldn't find anything about this in the literature.

The measure was done on the [http://www.shimadzu.eu/products/spectro/rf/rf5301/default.aspx Shimadzu Spectroscopy RF5301]

Tryptic digest of gel lanes for analysis with MALDI-TOF

Note:

- Make sure to work under a fume hood.

- Do not work with protective gloves to prevent contamination of your sample with platicizers.

Reaction tubes have to be cleaned with 60 % (v/v) CH3CN, 0,1 % (v/v) TFA. Afterwards the solution has to be removed completely followed by evaporation of the tubes under a fume hood. For the probes microtiter plates from Greiner® (REF 650161) can be used without washing.

- Cut out the protein lanes of a Coomassie-stained SDS-PAGE using a clean scalpel. Gel parts are transferred to the washed reaction microtiter plate. If necessary cut the parts to smaller slices.

- Gel slices should be washed two times. Therefore add 200 µL 30 % (v/v) acetonitrile in 0,1 M ammonium hydrogen carbonate each time and shake lightly for 10 minutes. Remove supernatant and discard to special waste.

- Dry gel slices at least 30 minutes in a Speedvac.

- Rehydrate gel slices in 15 µL Trypsin-solution. The Trypsin-solution contains 1 µL Trypsin and 14 µL 10 mM NH4HCO3

- Gel slices have to be incubated 30 minutes at 4 °C, followed by incubation at 37 °C over night.

- Dry gel slices at least 30 minutes in a Speedvac.

- Samples can be used for MALDI measurement or stored at -20 °C.

Preparation and Spotting for analysis of peptides on Bruker AnchorChips

- Add 15 µL 50 % (v/v) ACN / 0,1 % (v/v) TFA to the dry gel slices.

- Spot 1 µL sample aliquot

- after the sample aliquot desiccated a little 1 µL HCCA matrix solution could bee added to the spotted sample aliquots. Pipet up and down approximately five times to obtain a sufficient mixing. Be careful not to contact the AnchorChip.

Note: Most of the sample solvent needs to be gone in order to achieve a sufficiently low water content. When the matrix solution is added to the previously spotted sample aliquot at a too high water content in the mixture, it will result in undesired crystallization of the matrix outside the anchor spot area.

- Dry the prepared spots at room temperature

- Spot external calibrants on the adjacent calibrant spot positions. Use the calibrant stock solution (Bruker’s “Peptide Calibration Standard II”, Part number #222570), add 125 µL of 0.1% TFA (v/v) in 30% ACN to the vial. Vortex and sonicate the vial.

- Mix the calibrant stock solution in a 1:200 ratio with HCCA matrix and deposit 1 µL of the mixture onto the calibrant spots.

Substrate analysis

Stock solutions

The estradiol, estrone, ethinyl estradiol, diclofenac, ibuprofenand naproxn where dissolved in methanol in a concentration of 1 mg mL-1 and stored at -20 °C in glas bottles. Naphthalene, acenaphthen, phenanthren and anthracen where dissolved in acetonitrile in a concentration of 1 mg mL-1 and stored at -20 °C in glas bottles.

Sample preparation

For the degradation of our substrates we used following standard reaction:

| Material | Volume | concentration |

|---|---|---|

| Robinson Buffer | 1275 µL | |

| Substrates | 75 µL | 10 µg mL-1 |

| [http://www.sigmaaldrich.com/catalog/product/sigma/53739?lang=de®ion=DE Laccase] | 150 µL | 0.1 U |

| (ABTS | 15 µL | 0.1 mM) |

Aliquots of 200 µl per reactiontube where stopped over a span of 12 houres, for reactions without ABTS. With redox mediator we mesured over a span of 30 minutes. The reactions was stoped with 80% Methanol. This changed the substrate concentration to 2 µg mL-1. If we used the samples directly after the degradation the samples were transered into HPLC vials. Otherwise we stored them at -20 °C.

HPLC

High performance liquid chromatography (HPLC), a sort of liquid chromatography, is an analytical method in chemistry, not only to separate substances, but also to identify and quantify these substances using internal standards.

The examined substance, together with a mobile phase, is pumped through a separation column, the stationary phase. You can classify an HPLC according to the principle of separation in normal phase (NP), reverse phase (RP), ion exchange (IEC), size exclusion (SEC) and chiral chromatography. The substance to be tested is injected into the stream of the mobile phase in small amounts. The movement of the sample through the column depends on the nature of the sample on the one hand and the stationary phase on the other hand. If one component of the tested substance interacts strongly with the stationary phase, it remains on the column relatively long. If the interaction of a substance is weak, its velocity to leave the column is higher. The time at which a specific substance elutes is called retention time and is suitable for identification under particular conditions.

Our HPLC specifications:

- C18 reverse phase column

- Isocratic method: 60 % Acetonitrile

- Flow = 0.5 mL min-1

- Fluorescence-detection

- Column:

- Eurospher II 100-3 C18p by [http://www.knauer.net/ Knauer]

- Type of column: Vertex Plus Column

- Precolum

- Oven temperature 30 °C

- Software:

- Clarity (Version 4.0.0.681) by [http://www.dataapex.com/ Data Apex]

- Autosampler:

- Midas by [http://www.spark.nl/ Spark Holland]

- Tray cooling: 4 °C

- Pump:

- L-6200A Intelligent Pump by [http://www.hitachi.com/ Hitachi]

- Fluorescence-Detector:

- RF-551 by [http://www.shimadzu.de/ Shimadzu]

Protocol to regenerate the RP-packings:

- Flush the column with 20 volumes of water

- Flush the column with 20 volumes of acetonitrile

- Flush the column with 5 volumes of isopropanol

- Flush the column with 20 volumes of heptane

- Flush the column with 5 volumes of isopropanol

- Flush the column with 20 volumes of acetonitrile

Liquid chromatography–mass spectrometry

This method can be used to seperate analyts to analyzed with mass-spectrometry. We used this technique to identify degradation products after the Laccase treatment to our Substrates.

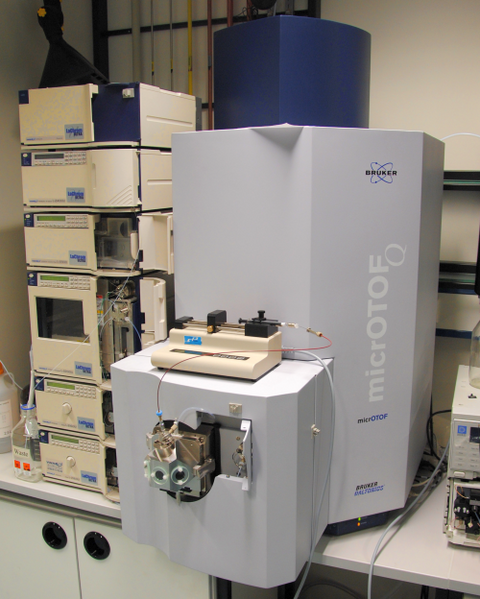

For the LC-ESI-qTOF-MS we had the [http://www.bdal.com/products/lc-ms/o-tof/microtof-q-ii/overview.html micrOTOF-Q II™] by Bruker Daltonics available.

We used this Methode to analyze degradation products of Estradiol, Estron, Ethinyl estradiol and Anthracen.

SPE-Column purification

To remove unwanted analytes from the samples we used [http://www.phenomenex.com/Products/SPDetail/Strata/C18-E?returnURL=/Products/Search/SPE C18E-SPE-Columns]. Since we don't know anything about the degradation products the columns were used to make a proof of concept. Therefor following steps were necessary to regenerate the column and solve the products from the column:

- 2 ml (8:2 v/v) water-aceton,

- 2 ml Methanol,

- 2 ml Water,

- pipett Sample to the column,

- 2 ml Water,

- 2 ml (8:2 v/v) water-aceton

- and the elution with 1 ml Methanol

after each step we centrigufed the column in 800g.

Running Methode and Mass-spectrometry

- Running Sample

- Flow Rate 0,3 ml/min

- Flowing medium A: Water + 0,1% Formic acid

- Flowing medium B: Acetonitril + 0,1% Formic acid

- Column: Bluespher 100 x 2 mm C18 by [http://www.knauer.net/ Knauer]

- Column temp. 40°C

- UV-light 230 nm

0 min 60% A and 40% B

2 min 60% A and 40% B

8 min 10% A and 90% B

10 min 10% A and 90% B

regeneration 15 min

- Mass spectrometry

- Dry Gas Temp. 180°C

- Nebulizer 2.0 Bar

- Dry Gas 8l/min

- Mass range 100 - 1000

- Capillary Voltage 4500V

Activity measurements

Determination of protein concentration via Bradford assay

- Prepare a mastermix containing 158 µL H2O and 40 µL BioRad solution for each sample.

- For creating a standard use 1, 1.5 and 2 mg/mL BSA.

- Allocate 198 µL of the mastermix in each well.

- Add 2 µL of the sample or standard.

- Use 3 replicats for each sample/standard.

- Measure the absorbency at 595 nm.

Determination of protein concentration via Nanoquant assay

Rebuffering samples via [http://www.sigmaaldrich.com/content/dam/sigma-aldrich/docs/Supelco/Product_Information_Sheet/4774.pdf HiTrap Desalting Columns]

- Equilibrate the column by giving 25 mL of the desired buffer on the column.

- Apply the buffer with a syringe to let it insert completely.

- As well with a syinge, add 1.5 mL of the sample to the column and let it insert completely.

- Add 2 mL of the desired buffer and let it insert completely while collecting the first 2 mL eluted through the column.

- Clean column by rinsing it with 25 mL of 20% EtOH, as well applied with a syringe.

- Store column filled with 20% EtOH in the refrigerator.

General setup of enzyme activity measurements

For the measurements [http://www.sigmaaldrich.com/catalog/product/sigma/m0312?lang=de®ion=DE 96-well flat bottom multiwell plates] were used. Each well contained a total sample volume of 200 µL respectively. The sample setup was pipetted as follows:

| component | concentration |

|---|---|

| buffer: | 100 mM |

| Laccase | 0,1 U |

| [http://www.sigmaaldrich.com/catalog/product/sigma/a1888?lang=de®ion=DE ABTS] | 0,1 mM |

| H2O | ad 200 µL |

The [http://www.sigmaaldrich.com/catalog/product/sigma/53739?lang=de®ion=DE Laccase of T. versicolor] we bought for standardization was diluted in water so that 140 µL would contain 0,1 U meaning 72 x 10-5 g of the enzyme. Please check the labjournal if Sodium-Acetate or Briton Robinson Buffer was used, respectively. The ABTS and laccase concentration optimum for a traceable reaction during standardization was determined during several experiments. Check the labjournal for further information. If activity of heterologous expressed laccases was going to be determined a pre-incubation with 0.4 mM CuCl2 for 2 hours on ice was necessary.

Setup for activity measurements at different temperatures

The setup for temperature measurements was conducted in the same sample composition as in the general setup. Each reaction contained 0,003 mg/mL laccase, 100 mM sodium acetate buffer (pH 5), 0,1 mM ABTS to a final volume of 1.4 mL (n=3). For a time frame of three or more hours three 1.5 mL reaction tubes are necessary. To measure the reaction at the desired temperatures heating blocks were used. Each 15 minutes after insertion of ABTS samples of 200 µL are taken and quickly loaded in a 96-Well flat bottom plate to measure with the TecanReader at OD420. Measurements are taken out for up to 5 hours. As a blank the reaction setup without ABTS is used. The negative control is measured without addition of laccase.

Carbon source measurement with HPLC

During the cultivation of the different strains of E. coli to produce our laccases, the concentration of the carbon source was measured using HPLC. For the fermentations with HSG medium with measured the change of the initial glycerine concentration. The same method can also be used for the detection of glucose, ethanol and methanol.

- Centrifuge 2 mL of cultivation supernatant for 15 min x 15000 rpm.

- Transfer at least 800 µL of the cleared centrifugation supernatant into a HPLC vial.

- Add 2 µL of 100 g L-1 sodium azide

- External standards are different concentrations of glycerine (

| 55px | | | | | | | | | | |

"

"