Team:Tokyo Tech/Projects/PHAs/index.htm

From 2012.igem.org

Contents |

Achivement

We made a new biobrick part and succeeded synthesizing Polyhydroixyalkanoates(PHAs). In our project, we designed rose silhouette to enhance the balcony scene of “Romeo and Juliet” by the synthesis of PHAs.

What is PHA?

Polyhydroixyalkanoates(PHAs) are biological polyester synthesized by a wide range of bacteria, and can be produced by fermentation from renewable carbon sources such as sugars and vegetable oils. These polyesters are biodegradable thermoplastics and elastomers, which exhibit interesting material properties. Bacteria produce PHAs for the storage of carbon and energy. When the bacteria can’t get enough nutrients from outside, these PHAs will be degraded and used as energy source. This function is quite similar to the one of lipid in human body. PHAs are also a kind of bio plastics, which can be biodegraded a lot faster than fossil-fuel plastics in the environment. Poly-3-hydroxybutyrate, P(3HB) is the most common type of PHAs. P(3HB) is synthesized by the enzymes coded in the gene of PHA synthesis (phaC1-A-B1) from Ralstonia eutropha H16.

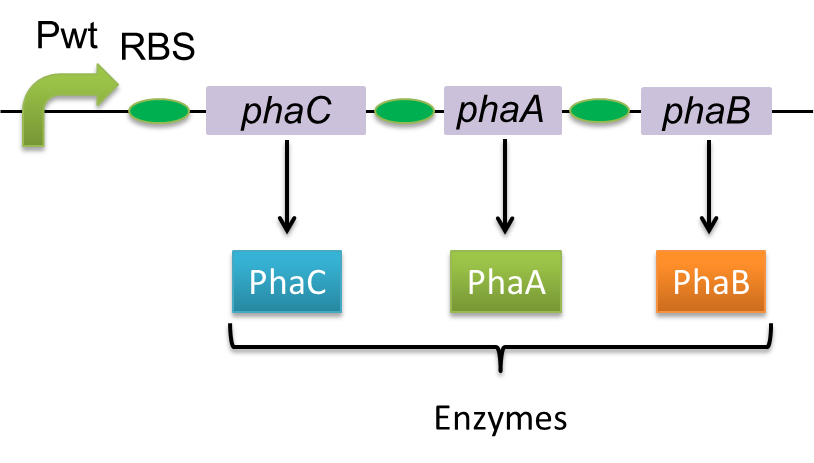

Poly-3-hydroxybutyrate, P(3HB) is synthesized by three enzymes.

The A gene encodes for the 393 amino acids protein, 3-ketothiolase (PhaA) The B gene encodes for the 246 amino acids protein, acetoacetyl-CoA reductase (PhaB) The C gene encodes for the 589 amino acids protein, PHA Synthase (PhaC)

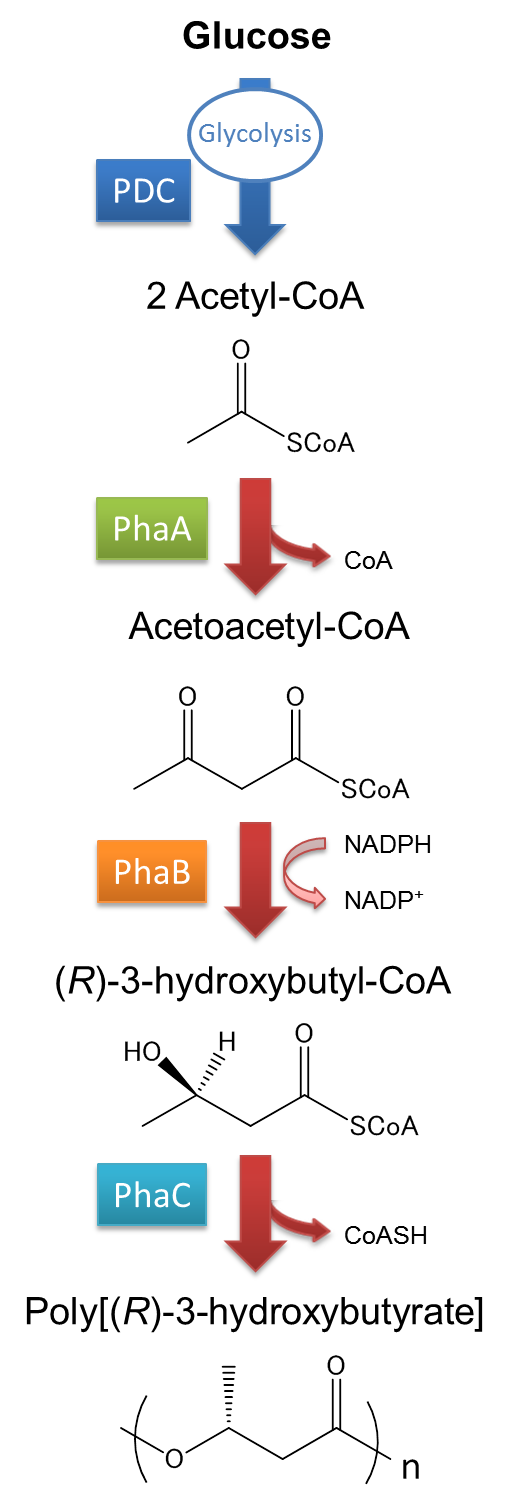

The pathway and regulation of P(3HB) synthesis in Ralstonia eutropha H16 is shown in Fig2. Acetyl CoA is metabolized from glucose by glycolysis and Pyruvate dehydrogenase complex (PDC). At first, two molecules of acetyl-CoA are ligated to one molecule acetoacetyl-CoA by the action of 3-ketothiolase (coded in phaA). Acetoacetyl-CoA is transformed into (R)-3-hydroxybutyl-CoA by NADPH dependent acetoacetyl-CoA reductase(coded in phaB). P(3HB) polymers are then synthesized by the polymerization of (R)-3-hydroxybutyryl-CoA by the action of PHA synthase (PhaC). In most of the cases, PHA synthase determines the characteristic of PHA being synthesized in microorganism.

Other teams

In this study, we constructed a part containing pha-C1-A-B1 in Biobrick format. We introduce some attempts in the past iGEM to show how great our work is in iGEM. There is no Biobrick part which worked as expected though some teams had tried to synthesize PHA in the past.

| iGEM10_Caltech |

| iGEM10_INSA-Lyon |

| iGEM09_Duke |

| iGEM08_Utah State |

| iGEM08_tsinghua |

| iGEM08_Hawaii |

| iGEM08_Virginia |

| Part number | Description | States | experience |

| [http://partsregistry.org/wiki/index.php?title=Part:BBa_K338003 BBa_K338003] | PHA Synthase Composite, Part 1/2 | planning | |

| [http://partsregistry.org/wiki/index.php?title=Part:BBa_K338004 BBa_K338004] | PHA Synthase Composite, Part 1/2 | Available |

They couldn’t prove that their engineered bacteria produced PHB according to the team wiki.

Production of PHAs by E.coli

Construction of pha-C1-A-B1 in Biobrick format

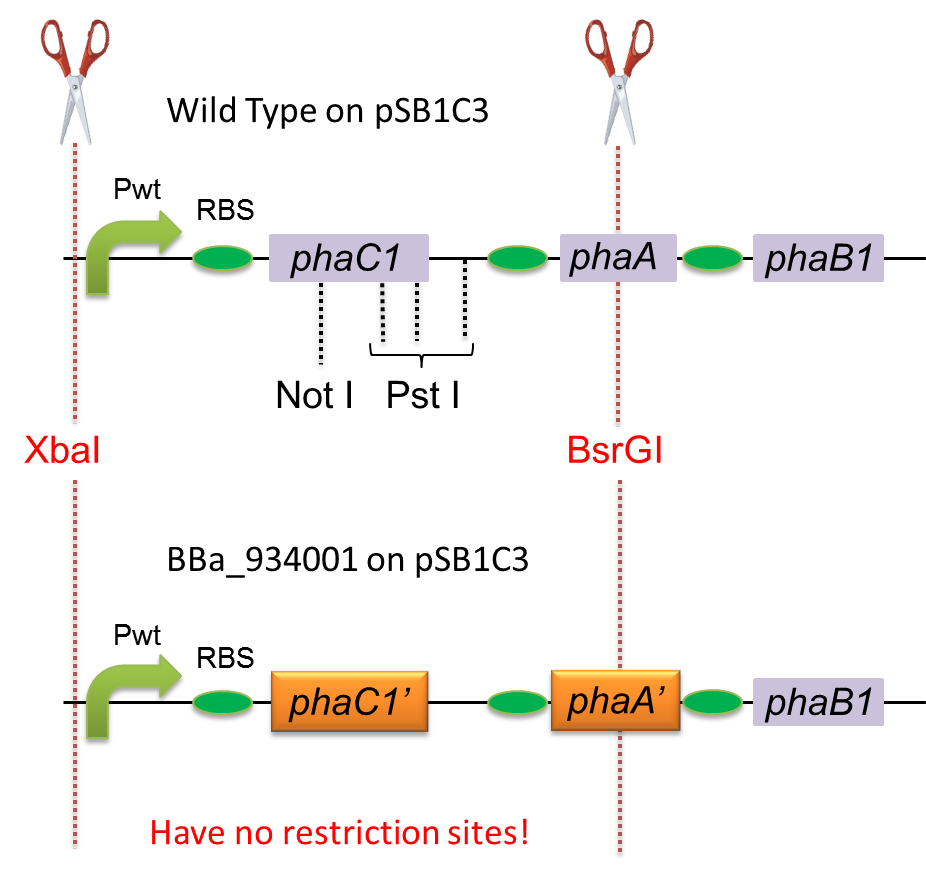

To construct a part that meets Biobrick format, we have modified the pha-C1-A-B1 operon not to contain forbidden restriction enzyme sites. First, we cloned the wild type gene pha-C1-A-B1 from R.eutropha H16 by using PCR and inserted the gene into pSB1C3. However, wild type pha-C1-A-B1 gene sequence contains one NotI and three PstI recognition sites that are not allowed in Biobrick format. To get pha-C1-A-B1 sequence without these recognition sites, we ordered the chemically synthesized DNA from IDT/MBL. In this chemically synthesized DNA, coding is optimized for E.coli. That is to say, we got PHB synthesizing gene in Biobrick format([http://partsregistry.org/wiki/index.php?title=Part:BBa_K934001 BBa_K934001]).

(1)Nile Red

Text

(2)Nile Blue

Text

Perspective

Text

"

"