Team:Cambridge/Biologger/Overview

From 2012.igem.org

(→Electrical) |

|||

| Line 87: | Line 87: | ||

The hardware/software electronic interface was realised using an Arduino microcontroller. The arduino circuitry, as illustrated on the left, is made up of our sensor, the motor, and a PCB or a breadboard (both were during our project). In cases where the motor to be used has too strong a starting torque a second transistor is required. The Bluetooth modem (Bluesmirf Gold) is an extra to be used when communication with mobile devices (e.g. with Android operating system) is required. The LDRs of our sensor sit in a biased potential divider circuit allowing for a direct ratiometric output without further calculations needed to be made in the software (more information, including testing data for our sensor can be found in the design page as well). | The hardware/software electronic interface was realised using an Arduino microcontroller. The arduino circuitry, as illustrated on the left, is made up of our sensor, the motor, and a PCB or a breadboard (both were during our project). In cases where the motor to be used has too strong a starting torque a second transistor is required. The Bluetooth modem (Bluesmirf Gold) is an extra to be used when communication with mobile devices (e.g. with Android operating system) is required. The LDRs of our sensor sit in a biased potential divider circuit allowing for a direct ratiometric output without further calculations needed to be made in the software (more information, including testing data for our sensor can be found in the design page as well). | ||

| - | The circuitry is incorporated into the mechanical chassis for an attractive, ergonomic overall design. The functionality of the system, including the sensitivity of our manually-made sensor setup orientated correctly using our manually-made cuvette holders was tested with success! The results can be seen in our [https://2012.igem.org/Team:Cambridge/ | + | The circuitry is incorporated into the mechanical chassis for an attractive, ergonomic overall design. The functionality of the system, including the sensitivity of our manually-made sensor setup orientated correctly using our manually-made cuvette holders was tested with success! The results can be seen in our [https://2012.igem.org/Team:Cambridge/Biologger/Results<u><span style="color:#000066">Results page.</span></u>] |

The code of the pre-set C++ program for driving the arduino can be found and downloaded in our [https://www.dropbox.com/sh/ol8727rn5o5ir0a/i5-6udXisJ<u><span style="color:#000066">Arduino Code download page.</span></u>]Note that there are two different programs: one for PCs and one for android devices. | The code of the pre-set C++ program for driving the arduino can be found and downloaded in our [https://www.dropbox.com/sh/ol8727rn5o5ir0a/i5-6udXisJ<u><span style="color:#000066">Arduino Code download page.</span></u>]Note that there are two different programs: one for PCs and one for android devices. | ||

Revision as of 01:14, 27 October 2012

Contents |

Judging Form

- Please help the judges by filling out this form. Tell them what medal you think you deserve and why. Tell them which special prizes you should win. Help them find your best parts. Show them how you thought about the safety of your project. Helping the judges will help you too.

- Team: Cambridge

- Region: Europe

- iGEM Year:2012

- Track:Foundational Advance

- Project Name:Parts for a reliable and field ready biosensing platform

- Project Abstract: Implementation of biosensors in real world situations has been made difficult by the unpredictable and non-quantified outputs of existing solutions, as well as a lack of appropriate storage, distribution and utilization systems. This leaves a large gap between a simple, functional sensing mechanism and a fully realised product that can be used in the field.

We aim to bridge this gap at all points by developing a standardised ratiometric luciferase output in a Bacillus chassis. This output can be linked up with prototyped instrumentation and software for obtaining reliable quantified results. Additionally, we have reduced the specialized requirements for the storage and distribution of our bacteria by using Bacillus' sporulation system. To improve the performance of our biosensing platform we have genetically modified Bacillus’ germination speed. Lastly, we demonstrated the robustness of our system by testing it with a new fluoride riboswitch, providing the opportunity to tackle real life problems.

iGEM Medals for non-software teams

- We believe our team deserves the following medal:

- Bronze

- Silver

- √Gold

Because we met the following criteria (check all that apply and provide details where needed)

Requirements for a Bronze Medal

- √Register the team, have a great summer, and plan to have fun at the Regional Jamboree.

- √Successfully complete and submit this iGEM 2012 Judging form.

- √Create and share a Description of the team's project using the iGEM wiki and the team's parts using the Registry of Standard Biological Parts.

- √Plan to present a Poster and Talk at the iGEM Jamboree.

- √Enter information detailing at least one new standard BioBrick Part or Device in the Registry of Standard Biological Parts. Including:

- √Primary nucleaic acid sequence

- √Description of function

- √Authorship

- Safety notes, if relevant.

- √Acknowedgment of sources and references

- √Submit DNA for at least one new BioBrick Part or Device to the Registry.

Additional Requirements for a Silver Medal

- √Demonstrate that at least one new BioBrick Part or Device of your own design and construction works as expected; characterize the operation of your new part/device.

- √Enter this information and other documentation on the part's 'Main Page' section of the Registry

Part Number(s): [http://partsregistry.org/Part:BBa_K911004 BBa_K911004]

Additional Requirements for a Gold Medal: (one OR more)

- Improve an existing BioBrick Part or Device and enter this information back on the Experience Page of the Registry.

Part Number(s): None - √Help another iGEM team by, for example, characterizing a part, debugging a construct, or modeling or simulating their system.

Link to this information on your wiki. Page name: Team:Cambridge/Outreach/Collaboration - √Outline and detail a new approach to an issue of Human Practice in synthetic biology as it relates to your project, such as safety, security, ethics, or ownership, sharing, and innovation.

Link to this information on your wiki.

Page name: Team:Cambridge/HumanPractices/Overview,Team:Cambridge/HumanPractices/MarketResearch,Team:Cambridge/HumanPractices/FutureDirections

iGEM Prizes

All teams are eligible for special prizes at the Jamborees. more... To help the judges, please indicate if you feel you should be evaluated for any of the following special prizes:

- √Best Human Practice Advance

- √Best Experimental Measurement

- Best Model

Please explain briefly why you should receive any of these special prizes:

Best Human Practice Advance:

We feel that we deserve this prize for three reasons:

- We explored the impacts, *both positive and negative*, of synthetic biology as a solution to real world problems, through interviewing professionals working in a relevant field, namely the impact of arsenic water contamination in Bangladesh.

- We recognized existing problems with the way the current direction of synthetic. On going through the registry we found that most of the characterization data for biosensing parts is often neither comparable nor replicable. We have worked to solve this issue, for example with our ratiometric dual channel output.

- *Our project doesn’t stop here*, in Chanel number 6 (Team:Cambridge/HumanPractices/FutureDirections) we considered the future implications and technological applications of our project, as well as the means by which it could be improved by subsequent users. We feel that the end to an iGEM project should not be the conclusion of an idea, but the start of it.

Best BioBrick Measurement Approach:

It is absolutely vital that a quantitative, numerical, robust, and flexible measurement approach exists to relay information to a user that is an accurate representation of the input processed by a biological device. Working from these principles, the following was done:

- We designed and built Biologger, a *cheap, arduino-based, fully functional automatic rotary device* that has an incorporated ratiolumnometer

- Our project is entirely open-sourced and open-platform. We have published source code for the two applications which serve to operate the device, one for PCs and the other for Android devices, as well as the open source circuit design that provides this ratiometric reading. Furthermore, the Android app is able to receive its data wirelessly, which we feel is a great advance in BioBrick measurement.

- Our dual-channel luciferase reporter was successfully tested with a dilution series of E.coli transformed with the Lux Operon (under pBAD) biobrick (Part BBa_K325909) of the Cambridge iGEM 2010 team. It can detect, with good accuracy, both different light intensities, as well as the percentages of blue or orange frequencies in a sample.

- Our device was successfully tested using artificial light to detect different frequencies (colours) as well.

Having done all the above, we believe that this fully open-sourced instrumentation kit (mechanical) chassis, electronics, software code), estimated at *$35.00* (or $85.00 if a Bluetooth modem is required), is a complete BioBrick measurement solution for any and all BioBricks with a light output.

Team_Parts

To help the judges evaluate your parts, please identify 3 of your parts that you feel are best documented and are of the highest quality.

- Best new BioBrick part (natural)

- [http://partsregistry.org/Part:BBa_K911003 BBa_K911003]

- Best new BioBrick part (engineered)

- [http://partsregistry.org/Part:BBa_K911004 BBa_K911004]

- Best improved part(s): None

List any other parts you would like the judges to examine:[http://partsregistry.org/Part:BBa_K911001 BBa_K911001], [http://partsregistry.org/Part:BBa_K911008 BBa_K911009], [http://partsregistry.org/Part:BBa_K911008 BBa_K911008]

Please explain briefly why the judges should examine these other parts:

- Magnesium Sensitive Riboswitch [http://partsregistry.org/Part:BBa_K911001 BBa_K911001]

As a riboswitch sensing construct, this part is an entirely new type of biosensor (along with the fluoride construct) that could potentially change the way we think about designing input genetic circuits. Unlike the fluoride riboswitch, it is a derepression system and therefore serves to demonstrate the principle that riboswitches can be used regardless of whether they turn on or off their reporter. - Fluorescent ratiometric construct for standardizing promoter output [http://partsregistry.org/Part:BBa_K911009 BBa_K911009]

Fluorescence is a major cornerstone for biosensors in the registry, however, most parts do not involve the use of a ratiometric output, which has been shown in the literature to provide much more reliable and meaningful data. This part not only furthers the development of ratiometric measurements in molecular biology but due to the choice of promoters and terminators it can be used to characterize the difference in activity between E. coli and B. Subtilis - Fast Germination (B. subtilis) [http://partsregistry.org/Part:BBa_K911008 BBa_K911008]

This part is entirely novel for the registry and fully utilizes the recombination machinery inherent in the Bacillus chassis. Have spores that can germinate at a faster rate is certainly a worthy achievement and could help with experiments with B. Subtilis that any future iGEM teams may wish to perform.

iGEM Safety

For iGEM 2012 teams are asked to detail how they approached any issues of biological safety associated with their projects.

The iGEM judges expect that you have answered the four safety questions Safety page on your iGEM 2012 wiki.

Please provide the link to that page: Page name: Team:Cambridge/Safety

Attribution and Contributions

For iGEM 2012 the description of each project must clearly attribute work done by the team and distinguish it from work done by others, including the host labs, advisors, and instructors.

Please provide the link to that page, or comments in the box below: Page name: Team:Cambridge/Attributions

Comments

If there is any other information about your project you would like to highlight for the judges, please provide a link to your wiki page here: Team:Cambridge/Overview/DesignProcess

Biologger Overview

Instrumentation (Biologger) was a vital aspect of our project in the development of the biosensing kit. The term instrumentation includes all the mechanical, electrical and software components which allow the incorporation of our multiple independent modules into a working and field-ready kit. The design process as well as the first experiments done that enabled the development of this kit can be seen at our Design process page. The Design page also includes further improvements that could be done on our Biologger kit. The results obtained after the testing of the instrumentation with biological samples as well as videos of our instrumentation in action can be seen in our Results page.

Mechanical

The mechanical chassis prototype, as can be seen from the image on the left, was made using two materials: foam and aluminium. Foam was chosen due to its easy manipulation and aluminium due to its excellent strength to weight ratio. The prototype includes a rotary mechanism (a central metal axon connected to the cuvette holder cylinder), which can be driven in steps by a DC electric motor (and a suitable code). It should be noted at this point that this is merely one possible implementation of suitable instrumentation and in particular it was one that could be developed as a prototype, always within the constraints of this project. We do not wish to claim that this is an ideal solution!

The purpose is that our self-developed sensor, which was made using two light dependent resistors (as can be seen in the design page), an orange and a blue theatrical filter, takes multiple readings from different biosensors, each found in a different cuvette. It should be noted that each cuvette holder is coated on the inside with highly reflective mylar film (image on the right). In this way, most of the light produced by the bacteria is concentrated for more accurate sensor measurements.

Electrical

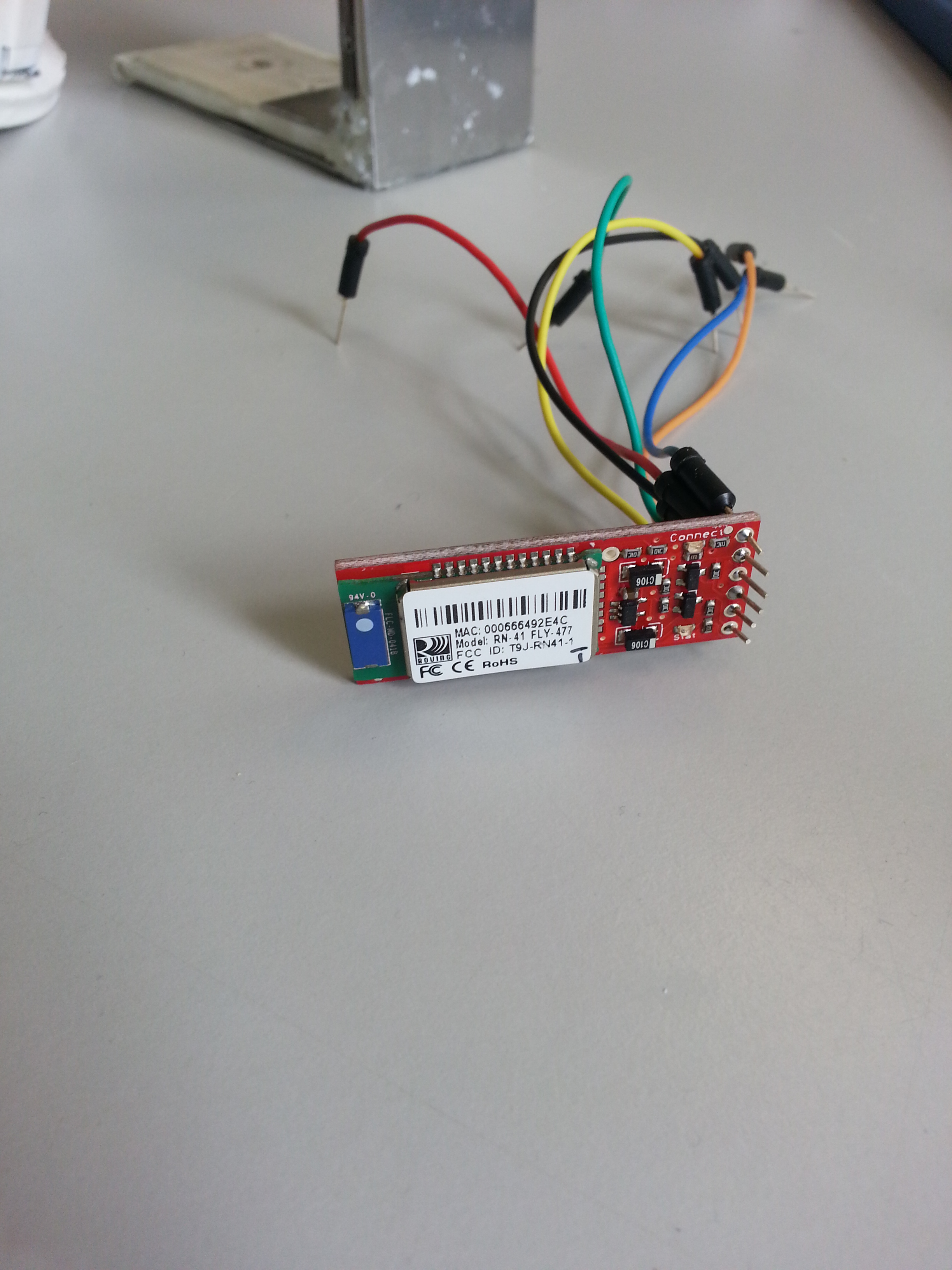

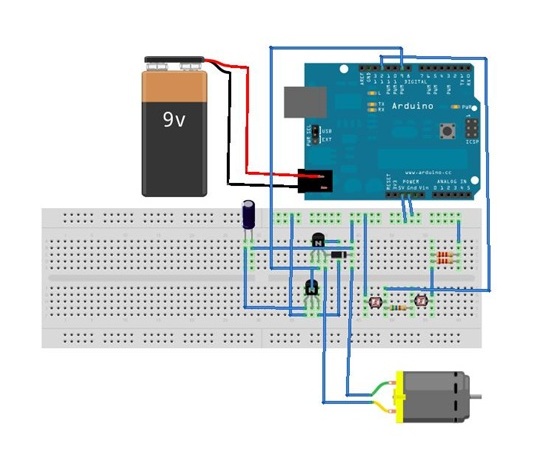

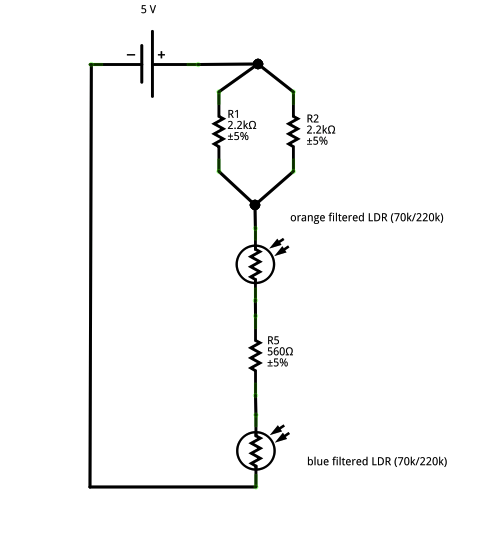

The hardware/software electronic interface was realised using an Arduino microcontroller. The arduino circuitry, as illustrated on the left, is made up of our sensor, the motor, and a PCB or a breadboard (both were during our project). In cases where the motor to be used has too strong a starting torque a second transistor is required. The Bluetooth modem (Bluesmirf Gold) is an extra to be used when communication with mobile devices (e.g. with Android operating system) is required. The LDRs of our sensor sit in a biased potential divider circuit allowing for a direct ratiometric output without further calculations needed to be made in the software (more information, including testing data for our sensor can be found in the design page as well).

The circuitry is incorporated into the mechanical chassis for an attractive, ergonomic overall design. The functionality of the system, including the sensitivity of our manually-made sensor setup orientated correctly using our manually-made cuvette holders was tested with success! The results can be seen in our Results page. The code of the pre-set C++ program for driving the arduino can be found and downloaded in our Arduino Code download page.Note that there are two different programs: one for PCs and one for android devices.

Below the schematic circuit diagram of the sensor can be seen together with the mathematical equation relating LDR resistances and sensor readings.

Software

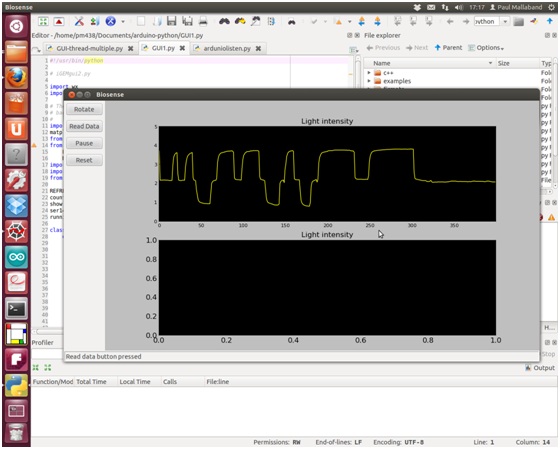

Software applications were developed, as mentioned before, for both PCs and android devices. This was done in order to provide extra flexibility as the potential use of our kit is field work. The computer software is written in the free open-source language python with cross-platform wxWidgets used to implement a GUI. The idea was to develop a fully functional GUI for collecting sensor data from all six inputs and display these as line graphs and in a final bar chart.

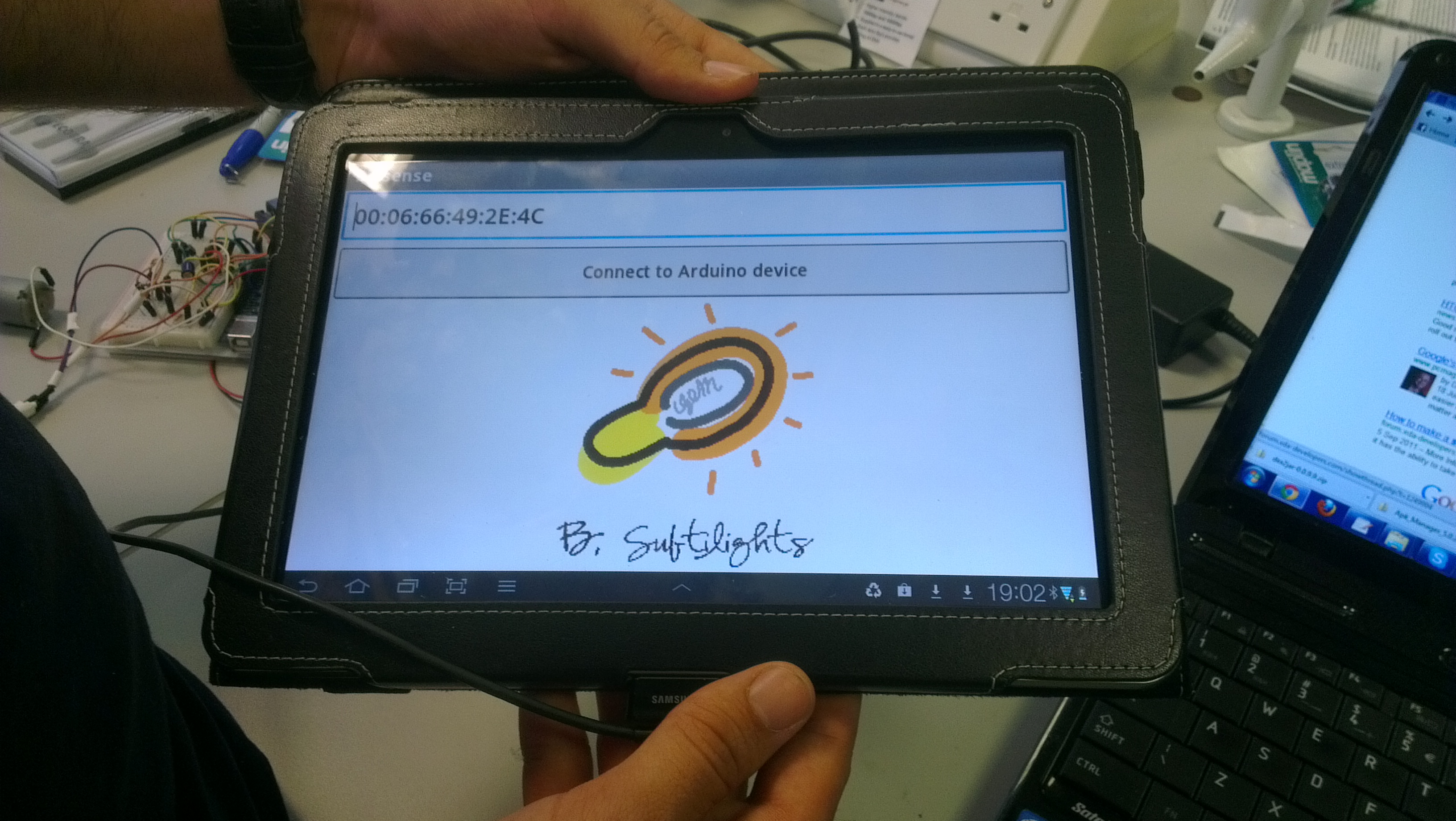

The image below on the right is a screengrab of the GUI under development and testing its ratiometric ability. The higher values are when one LDR is covered, the lower for the other and no change is observed when both are illuminated equally. By controlling the illumination, we managed to make our application write iGEM in morse code (image on the right)! The android GUI was made in Java using Eclipse editing mostly [http://www.amarino-toolkit.net/index.php/home.htmlAmarino] projects' open-source code (General Public License). The first screen (image below on the left) asks for the address of the Bluetooth modem connected to Arduino. B.Subtilights was the first logo of our team, and as we decided not to abandon it completely, it is the logo included in this application. This application is also functional as it can successfully connect, read real-time data and plot them on any Android phone/tablet.

The code (for programmers) as well as a ready application to be downloaded (for non-programmers this is the Bio_Logger.apk file) can be found in our Android application download page. The code for the Pyhton program can also be found and be downloaded in our Python software download page.

It should be noted that amarino_2.apk, found in the link above must also be downloaded on the android device for our application (Bio_Logger) to be perfectly functional, as it requires one of the amarino libraries.

Cost

One of the most important motives for the development of our project was that it offers a low-cost solution. Therefore, below there is an analysis of the biologger cost.

- Arduino Experimentation Kit

$25.00

- Light - dependent resistors 70kΩ/200kΩ

$2.00

- Colored Gel Filters

$2.00

- Materials for mechanical chassis

$6.00

Total $35.00

Optional: Bluesmirf Gold Bluetooth Modem $50.00

Total: $35/$85

"

"