Team:NRP-UEA-Norwich/Safety

From 2012.igem.org

(→Is there a local biosafety group, committee, or review board at your institution?) |

|||

| (77 intermediate revisions not shown) | |||

| Line 1: | Line 1: | ||

{{UEANRP}} | {{UEANRP}} | ||

| - | + | =Potential safety issues our project could raise:= | |

| + | When designing the experiments the NRP-UEA-Norwich team would undertake they had to consider not only the safety of the researchers and others within the lab, but also the public and the environment. They had to consider carefully the organisms and chemicals they would be using within lab, how they would handle these safely and then dispose of them after to minimize their effect on the environment and the public. | ||

| - | == | + | ==Researcher safety== |

| - | + | [[File:Joy_gloves.jpg |200px|left]]The University of East Anglia already has safety standards that have to be met, which included having basic safety training before starting wet lab work, as well as reading, understanding and signing relevant COSH forms for each potential lab procedure. Therefore, when designing experiments the NRP-UEA-Norwich team considered the risks associated and checked whether the COSH forms signed covered the procedures undertaken. The team also received training from advisors over the first few days of their time in the lab. They learnt what to do in emergencies, where to access the safety manual which is always within the lab, as well as being shown where to dispose of the different chemicals and used equipment. It is also vital that researchers within the university wear personal protective equipment (PPE), including lab coat, gloves and covered shoes. The members also wore protective face shields when using artificial UV light in the darkroom. In accordance with university regulation, the team was prohibited from eating, drinking or smoking in or near the lab. The team enjoyed their lunch well away from the lab, as well as being careful to wash their hands before leaving. | |

| - | |||

| - | The | + | The lab facilities were designed to be safe for the team members, providing plenty of space and clean surfaces to work on. The lab was supplied with plastic handheld pipettes, and permanent pens; removing the need for use researchers to ever use their mouths during experimentation e.g. mouth pipettes and labels that require saliva to aid adhesion. |

| - | |||

| - | The team had originally thought it would be interesting to look at NO levels within | + | The team had originally thought it would be interesting to look at NO levels within "Salmonella", but decided later that this would result in a lot more safety concerns and complications. Therefore, the team decided to only use strains of ''E.coli'' (which they had all used within their university studies before and were allowed to handle within the lab) within our projects. NEB 5-alpha ''E.coli'' was used to characterize existing BioBricks, as well as BL21 pLysS ''E. coli'' cells and Alpha select gold ''E.coli''. ''E.coli'' is a well-studied species of bacteria, with fairly predictable behavior, as well as being non-pathogenic (a bio safety level 1 bacteria). Therefore, all the students were able to use the ''E.coli'' within the university’s second year (category one and two) teaching labs. |

| - | |||

| - | + | The hybrid promoter was further characterized by being placed into the mammalian cell MCF7. This was carried out by an experienced member of the team. This caused no concern as the mammalian cells were used and kept under standard laboratory conditions. However, if these cells somehow did make it in to the body they would be recognized as non self cells and consequently destroyed by the immune system. | |

| - | |||

| - | + | Since the team’s project involves Nitric Oxide (NO) they had to consider the safety of the chemicals involved. It is important to note that all chemicals within the lab are supplied with a safety advice sheet that has been generated by the company it was manufactured by. NO has been classed as a dangerous gas which can be directly toxic to blood, lungs, pancreas and nervous system. Therefore, caution was taken when using NO (within the form of potassium nitrate) within the lab. | |

| + | |||

| - | + | [[File:Protection_of_ears.jpg |300px|right]] | |

| - | |||

| - | + | Another safety concern was the use of Ethidium Bromide (EtBr) during the agrose gel staining. Ethidium Bromide is a known carcinogen, therefore the team took care to follow the university's specific guidelines on working with carcinogens ([https://static.igem.org/mediawiki/2012/4/4b/UEA_Rules_for_working_with_carcinogens_in_laboratories.pdf Rules For Working With Carcinogens]), which include the use of protective equipment, gloves and the appropriate disposal of waste in order to minimize researcher exposure. | |

| - | |||

| - | + | In the preliminary discussions in which the experiments the team would carry out were discussed, careful consideration was taken to choose appropriate equipment. They considered the equipment’s safety to the researcher, as well as the practicality and quality of results gained. The team members used most of the discussed equipment and procedures already used during their first two years of their undergraduate degree. However, there were a few procedures such as NanoDrop spectrophotometery and fluorometery that had not been used by the team before. Therefore the team members received training from experienced members of staff in order to avoid accidents that could damage the researchers or the machine itself. Finally, there were always more experienced scientists present within the lab to advise the team further on how to use equipment safely. | |

| - | + | ==Public safety== | |

| - | The | + | The team always removed their lab coats and gloves, as well as washed their hands, before leaving the lab. This reduced the chance of bringing harmful bacteria or substances outside the laboratory environment. The team also took care to keep the laboratory windows shut, in order to reduce exposure to the outside world. |

| - | |||

| + | All contaminated waste was autoclaved on site before being collected and disposed of under controlled conditions, or for cleaning for reuse. | ||

| - | |||

| - | |||

| - | |||

| - | |||

| - | The | + | The team felt that it was important that the public were given the opportunity to understand and ask about procedures used in the laboratory, so they could form informed opinions about the safety and ethical implications of the teams work. The team took the opportunity at their public engagement event to explain the procedures they used in full detail. |

| - | |||

| - | + | At this public engagement event the team took transformed ''E.coli'' samples to the venues and public safety was a priority. Therefore, the plates were maintained in a UV box behind a sheet of plastic, limiting public physical interaction with the laboratory specimens. These plates were also sealed extensively using parafilm and were kept well away form any part of the venue holding or serving food products. | |

| - | + | ==Environmental safety== | |

| - | + | [[File:Rabbits_at_UEA.png| 300px||left ]]Data safety sheets that come with chemicals explain how to dispose of the chemicals correctly. These guidelines were adhered to rigidly since the local water providing company, Anglia water, carry out routine random samples on what is poured down the sink drains, and if a certain volume (volume is unknown to university, which encourages them not to put any waste down the sink) of listed chemicals are found, then the university is fined. | |

| - | |||

| - | + | There is a very low risk of damage to the environment as all bacteria will be stored safely within the lab. However, if the bacteria was to unexpectedly be released, there is very little threat on the environment, since the bacteria are standard autotrophic laboratory stains and therefore unlikely to survive. The ''E.coli'' stains used are also unlikely to replicate and therefore spread. Finally, due to using plasmids with a narrow host range horizontal gene transfer between bacteria within the environment is also very unlikely, as plasmids would not replicate if transferred to other organisms. | |

| - | + | =Safety issues our BioBrick parts could raise:= | |

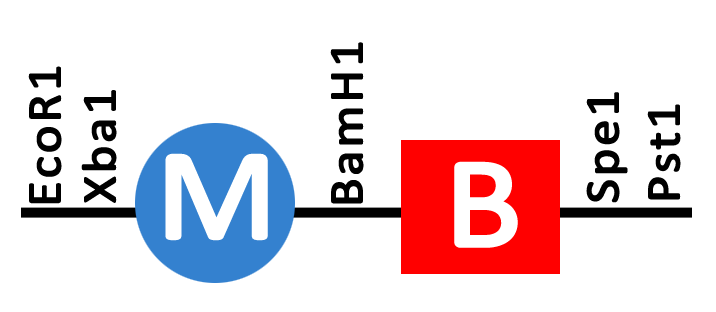

| - | + | The first BioBricks made by the NRP-UEA iGEM team are hybrid promoters consisting of a bacterial promoter (B) fused to a mammalian promoter (M); this has been carried out in two orientations, B upstream from M (B-M), and M upstream from B (M-B). As this is a new concept the BioBricks safety concerns arise, due to the lack of knowledge surrounding how the promoters will interact with one another. The team has not submitted any issues to the registry thus far as no specific issues have arisen, there are no specific concerns regarding the DNA sequence and both promoters are individually well characterised; however the team remains vigilant and understands that with unknown BioBricks such as B-M and M-B there is always the chance for something unexpected to occur. | |

| - | |||

| - | + | [[File:MB.png|200px|right]] | |

| + | [[File:BM.png|200px|right]] | ||

| - | + | The team has also synthesised a second new construct known as the comparator circuit, which again is not well characterised. Through its intended use is as a gene regulation component a risk arises in that the comparator circuit could possibly join to unintended, functional genes and affect their regulation. As no specific issues have arisen yet no issues have been added to the registry, however upon characterisation of the BioBricks any issues that do arise will immediately be included with the part. | |

| + | |||

| + | |||

| + | Throughout the project the team handled all safety issues by following and complying with both government safety standards as well as university safety standards. The team has also inserted the BioBricks into narrow host-range plasmids (as produced by iGEM), thus reducing the chances of horizontal gene transfer. BioBricks of B-M, M-B, and the comparator circuit, were all transformed into standard BSL1 laboratory autotrophic strains of ''E. coli'' and are therefore unlikely to survive outside of the laboratory. | ||

| + | |||

| + | |||

| + | Future iGEM teams could increase their safety by connecting the B-M and M-B BioBricks to a suicide gene. This would mean that in the unlikely event of the transformed cells being released into the environment and unintended bacteria taking up the BioBrick-containing plasmid, the unintended bacteria would be destroyed and further spread of the hybrid promoter BioBricks would be prevented. | ||

| + | |||

| + | =The University of East Anglia's biosafety review board= | ||

| + | |||

| + | UEA takes both staff and student safety very seriously and has its own health and safety policies and biosaftey rules that must be followed: [https://static.igem.org/mediawiki/2012/2/2e/UEA_GMO_rules.pdf UEA Genetically Modified Organisms Guidelines], [https://static.igem.org/mediawiki/2012/6/65/UEA_statment_of_health_and_saftey_policy.pdf UEA Health and Saftey Policy] and [https://static.igem.org/mediawiki/2012/6/68/UEA_Microbiological_saftey_rules.pdf UEA Microbiological Saftey Rules and Guidelines]. These have been created to follow the guidelines and biosafty rules that have to be considered in the United Kingdom as seen here [http://www.hse.gov.uk/biosafety/gmo/law.htm 'GMOs and the Law'] and [http://www.hse.gov.uk/biosafety/gmo/acgm/acgmcomp 'The SACGM Compendium of guidance']. All of our projects are in compliance with both university requirements and national regulations. | ||

| + | |||

| + | |||

| + | The university also has its own biosafety committee in which the responsibilities of different aspects of safety are split between departments and staff. Dr Andrew Hemmings is the BIO safety officer at UEA and spoke to members of the team about the project and discussed whether our COSH forms covered the processes carried out. The team then discussed their project further with other members of staff including Dr Mark Coleman, university GMO safety officer, and Dr Gabriella Kelemen, university microbial safety officer. | ||

| + | |||

| + | |||

| + | When speaking to members of the UEA biosafty team there was no concern with the processes being carried out and the bacteria being used. When the team spoke to GMO safety officer, Dr Mark Coleman, about the safety of the BioBricks they intended to create he said "there is a highly improbable chance this project poses a significant risk to either human health or the environment". | ||

| + | |||

| + | =Making future iGEM competitions safer through biosafety engineering= | ||

| + | |||

| + | Although the team started looking at NO, the dangers of unintentional exposure to NO soon became clear. Therefore, the team would hope that through using systems similar to our comparator sensor, NO sensors will be produced that are in the form of a sheet of paper and can be placed on the wall of labs, and buildings ect, to indicate excess levels of NO visually. | ||

| + | |||

| + | |||

| + | The team feels that future iGEM teams could aim to reduce the chance of horizontal gene transfer further by reducing the adherence between the transformed cells and others, or via the prevention of transformations without inducing competency. This would be a procedure to prevent some cases of antibiotic genes being passed through between bacterial species. However, a variety of other safeguards could also be deployed to prevent this. | ||

Latest revision as of 02:02, 27 September 2012

"

"