Team:Peking/Project/3D/Future

From 2012.igem.org

| Line 24: | Line 24: | ||

<div class="floatC"> | <div class="floatC"> | ||

<img src="/wiki/images/7/7c/Peking2012_Printing_Future.png" alt="Figure 3." style="width:500px;"/> | <img src="/wiki/images/7/7c/Peking2012_Printing_Future.png" alt="Figure 3." style="width:500px;"/> | ||

| - | <p class="description">Figure 1. Three-dimensional printing will have wide applications in the future.</p> | + | <p class="description" style="text-align:center;">Figure 1. Three-dimensional printing will have wide applications in the future.</p> |

</div> | </div> | ||

</div> | </div> | ||

</html>{{Template:Peking2012_Color_Epilogue}} | </html>{{Template:Peking2012_Color_Epilogue}} | ||

Revision as of 18:38, 26 September 2012

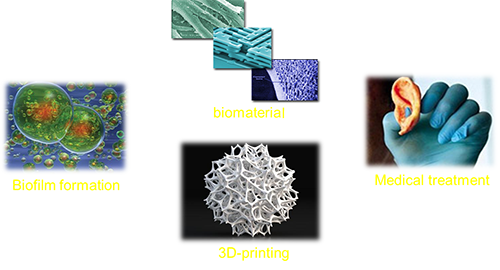

Prospective of Bio-printing

Bio-printing is not only a simple demonstration in our project, but it may also play an important part as an interface between physical environmental factors and organisms, as well as a vital inducer in highly organized biomaterial formation. For the first time, our project demonstrated that bio-printing is feasible even in weak and incoherent light.

Biofilms are an aggregation of cells in which they adhere together on a surface. Previous studies mainly focused on chemical-induced biofilm formation. Their limitations are usually inevitable because induction requires the chemical(s) to physically contact the receiver cells. Problems include the remnants of chemicals on biofilm, the diffusion of inducers, and possible impairments on fragile biofilm when applying inducer chemicals. When combined with bio-printing, light-induced biofilm formation may provide an environmentally friendly way to produce biofilms with greater precision. For example, with beam(s) of highly coherent light, it may be possible to control cells on the unicellular level.

A single bacterium is about 1μm long and its metabolic products are on the nanometer scale. Once the control of a single cell is made possible, we can obtain control of biomaterial formation on the nanometer scale. The memory space of a piece of Blu-Ray disk is about 25 gigabytes, however, once our parts are utilized to control a single cell, a normal sized bio-disk made of metabolites would be able to store information in terabytes or on an even larger scale.

Instead of printing 2D images layer by layer to create a 3D image, more precise control of the threshold of our optic biosensor and optimized receiver circuit may allow for the first holographic image from a cluster of cells to be plausible i.e., a real 3D photo-printing method in synthetic biology discipline. Once cell differentiation is adaptable, artificial tissues or organs could be obtained by 3D photo-printing with a cluster of rewired stem cells.

With our highly-sensitive optically responsive Luminesensor, bio-printing by natural light is finally a reality. The responding wavelengths necessary are in the visible light spectrum, making them harmless, which further proves that our parts are suitable for printing on organisms.

Figure 1. Three-dimensional printing will have wide applications in the future.

"

"