Team:Valencia Biocampus/modeling1

From 2012.igem.org

Alejovigno (Talk | contribs) (→Are you hot?) |

Alejovigno (Talk | contribs) (→Are you hot?) |

||

| Line 17: | Line 17: | ||

During this 40 minutes delay, the microorganism was growing. Therefore, the heat shock in batch no. 2 was applied to a larger population than in the case of batch no.1. Consequently, the measurements of FI and DO gave much higher values. This affects the ratio FI/DO, were the two batches can be clearly distinguished (see figure 1). | During this 40 minutes delay, the microorganism was growing. Therefore, the heat shock in batch no. 2 was applied to a larger population than in the case of batch no.1. Consequently, the measurements of FI and DO gave much higher values. This affects the ratio FI/DO, were the two batches can be clearly distinguished (see figure 1). | ||

| - | [[Image:HSrawData.png | + | |

| + | <center> | ||

| + | <table border="0.01" style="background-color:transparent"> | ||

| + | <tr> | ||

| + | <td width ="400" align="center">[[Image:HSrawData.png|center|400px]]</td> | ||

| + | </tr> | ||

| + | <tr> | ||

| + | <td width ="400" align="justify"><b>Figure 1.</b><br> Raw data from the heat shock experiment.</td></tr> | ||

| + | </table> | ||

| + | |||

| + | |||

| + | [[Image:HSrawData.png|center|660px]] | ||

Our first modeling work was to perform data reconciliation. To this end, we assume that during this 40 minutes delay the only thing that happended was that cells grew. Growth was approximately linear in the range analyzed, as seen in figure 1 (blue data). We fitted a simple model DO=p1+p2*t. The result can be seen in figure 2, were: | Our first modeling work was to perform data reconciliation. To this end, we assume that during this 40 minutes delay the only thing that happended was that cells grew. Growth was approximately linear in the range analyzed, as seen in figure 1 (blue data). We fitted a simple model DO=p1+p2*t. The result can be seen in figure 2, were: | ||

Revision as of 14:50, 26 September 2012

Contents |

Modeling Bacteria

Here we modeled several of the Bacteria constructions.

Are you hot?

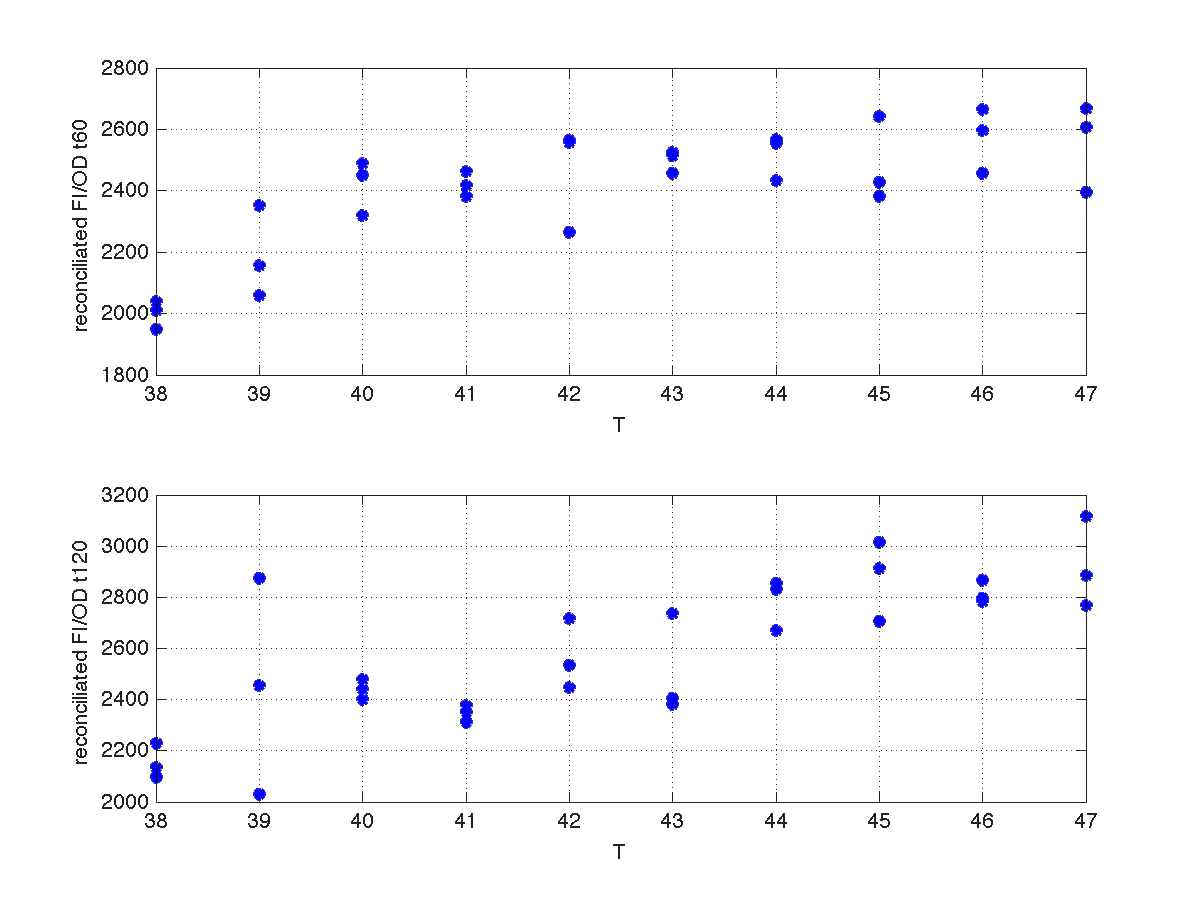

For the case of the Heat Shock promoter, we decided to model the static transfer function of the Fluorescent Intensity as a result of the Temperature with the folow equation:

In order to estimate the parameters of this model we performed a heat shock experiment.

Analysis corresponding to a heat shock applied during 10 minutes at different tempe-ratures ranging from 20ºC up to 51ºC. For each temperature three samples were tested. Fluorescence Intensity (FI) and optical density (OD) were measured at t1=60 minutes and t2=120 minutes after application of the heat pulse had finished.

The first practical problem we encountered was the lack of enough heating coats. Be-cause of these we took the culture, and we splitted the experiments in two batches. FI and OD were measured at t1=60, and t2=120 for batch number 1, while for batch number 2 the heat shock was delayed by 40 minutes with respect to the first batch. Therefore, measu-rements for batch no.2 were taken at t1=100, and t2=160 minutes respectively.

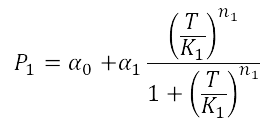

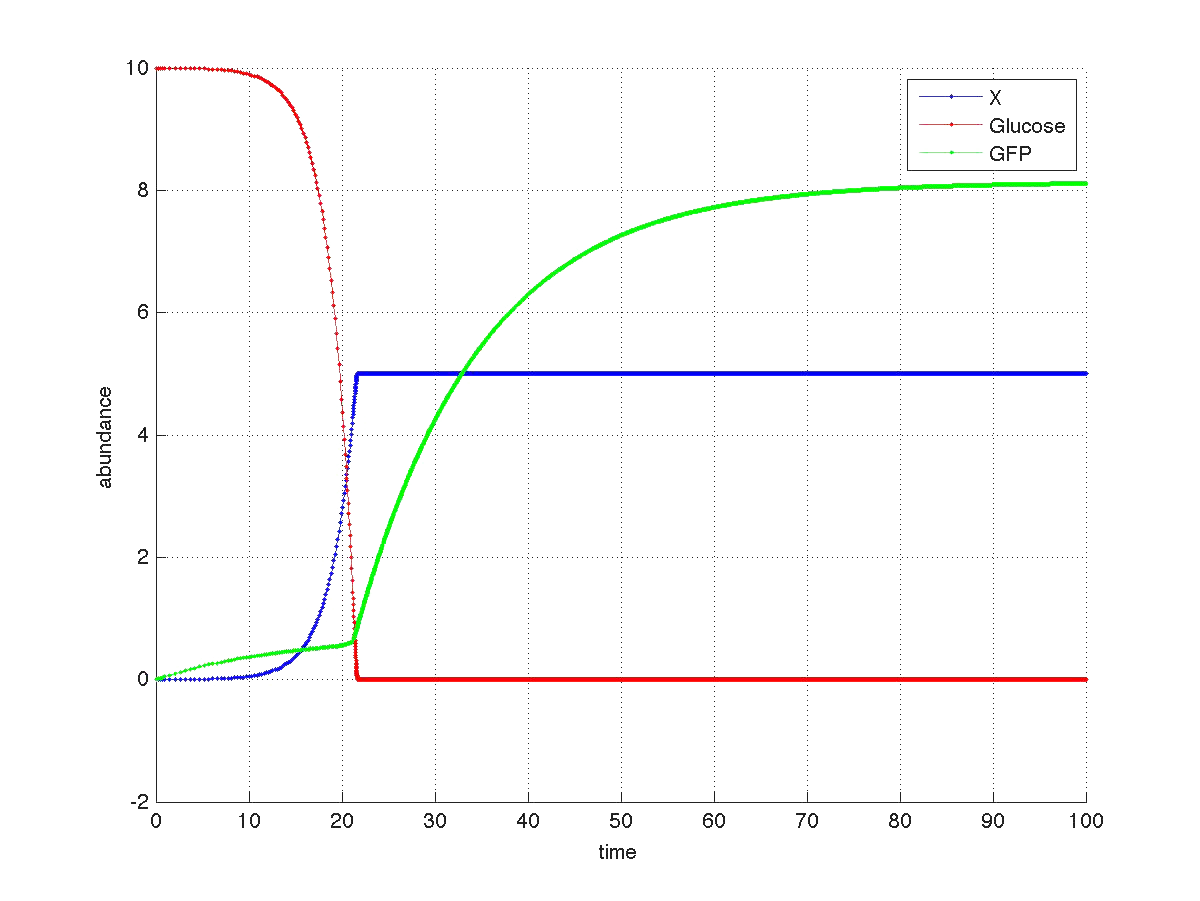

During this 40 minutes delay, the microorganism was growing. Therefore, the heat shock in batch no. 2 was applied to a larger population than in the case of batch no.1. Consequently, the measurements of FI and DO gave much higher values. This affects the ratio FI/DO, were the two batches can be clearly distinguished (see figure 1).

| Figure 1. Raw data from the heat shock experiment. |

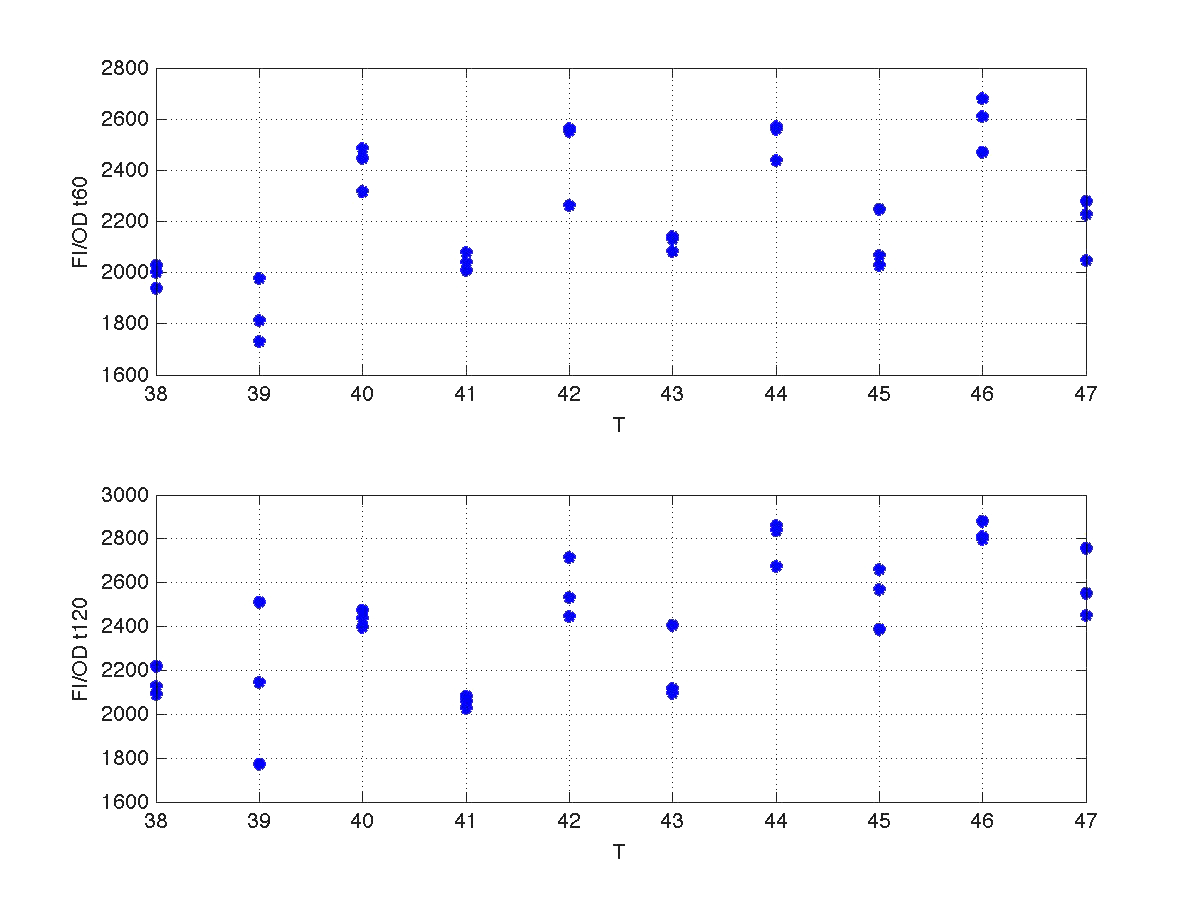

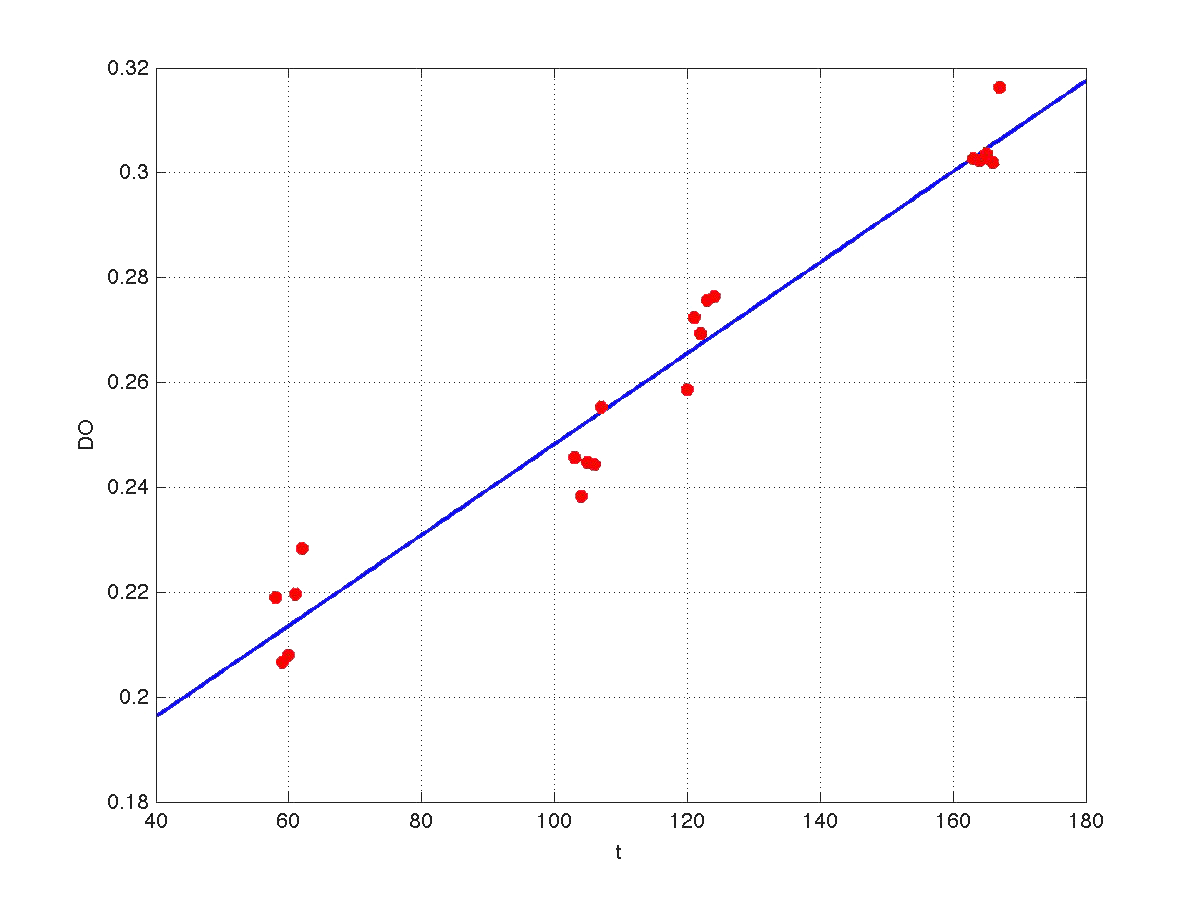

Our first modeling work was to perform data reconciliation. To this end, we assume that during this 40 minutes delay the only thing that happended was that cells grew. Growth was approximately linear in the range analyzed, as seen in figure 1 (blue data). We fitted a simple model DO=p1+p2*t. The result can be seen in figure 2, were: p1 = 0.161573 p2 = 0.000866314 Therefore, the ratio FI/DO above can be compensated by multiplying data by the frac-tions (p1+p2*t100)/(p1+p2*t), and (p1+p2*t160)/(p1+p2*t). Actually, what we did was to compensate all measurements to the same time base. The reconcialited result can be seen in figure 3.

Once we had all data reconciliated we fitted it to a static model relating the ratio be-ween fluorescence intensity (FI), and the culture optical density (OD) with the temperature applied during the heat shock.

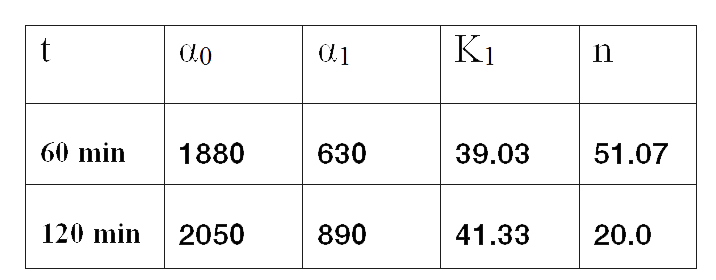

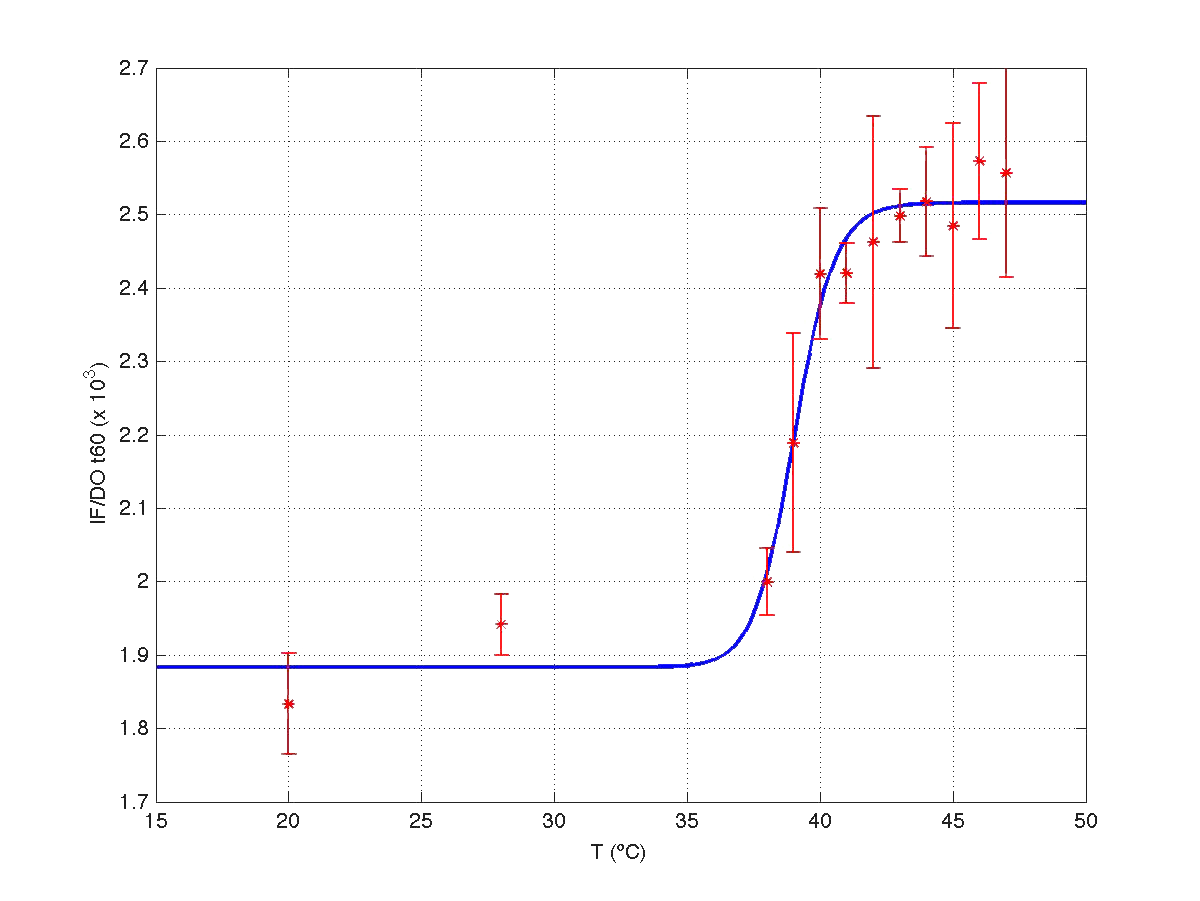

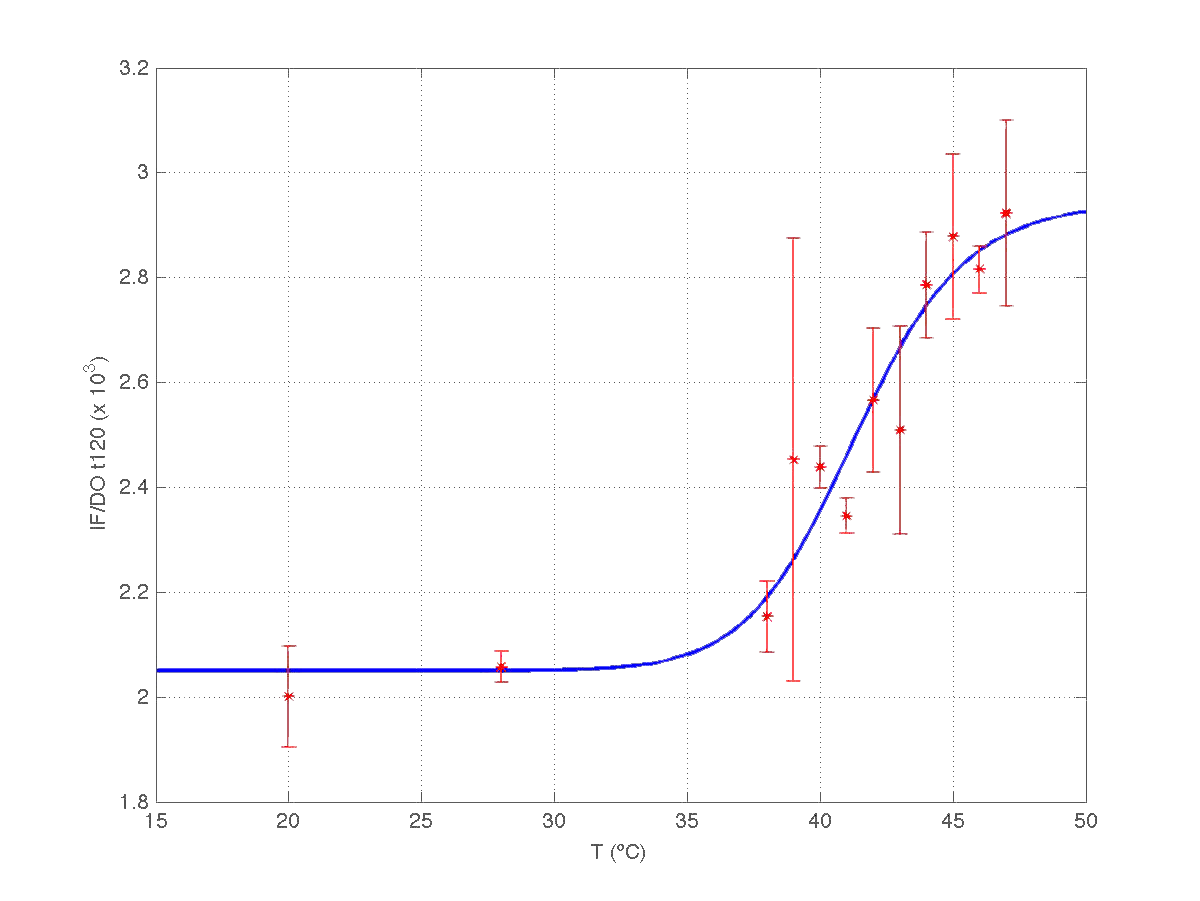

Since the model is nonlinear with respect to parameters K1, and n, we applied a global op-timization algorithm based on stochastic search. Actually we applied it to fit the data at t=60 minutes, and t=120 minutes independently. The estimated parameters were:

The results can be seen in figures 4 (t60), and 5 (t120) respectively.

Modeling Yeast

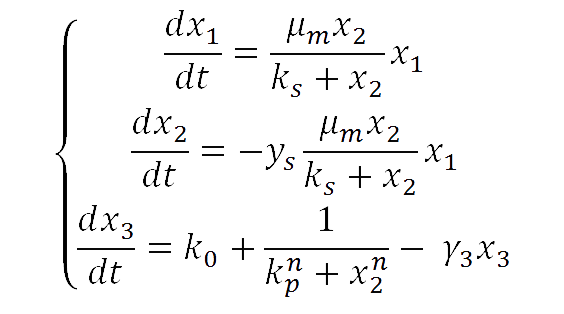

For our yeast construct: How long have you been fermenting? we propose a phenomenological model to explain the relationship between glucose concentration and fluorescent protein production. The following model was assumed:

where

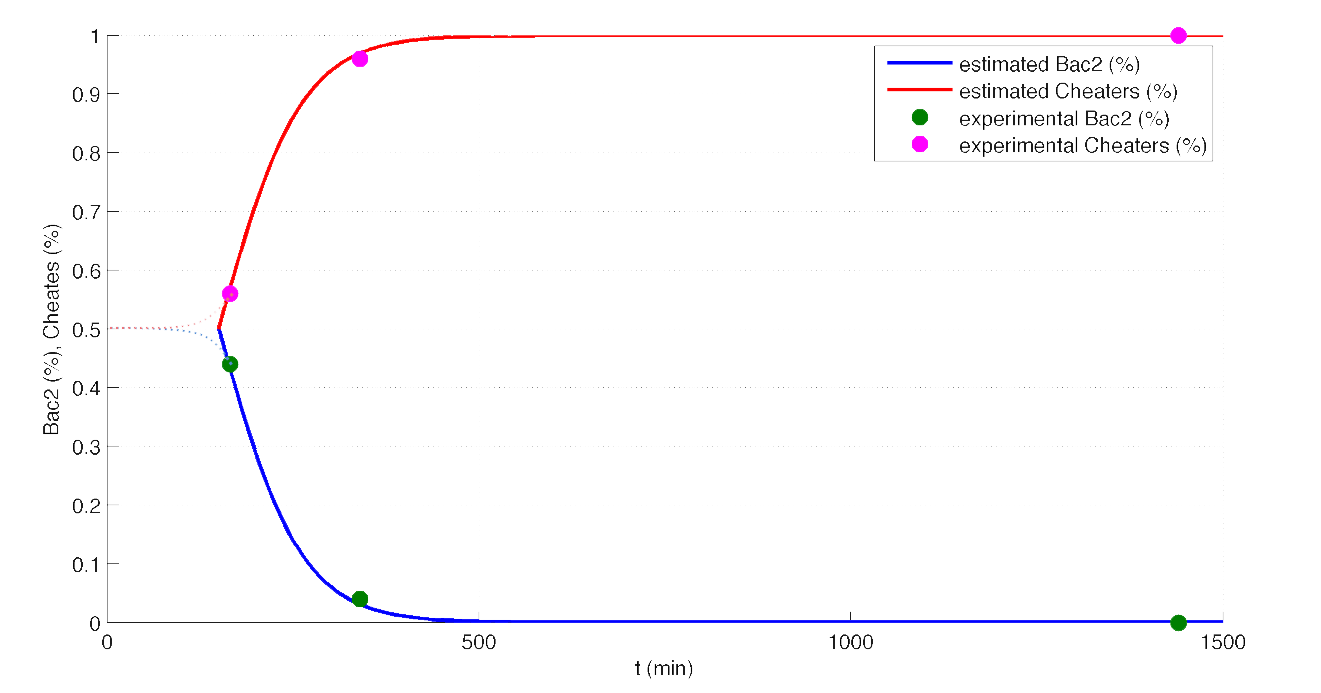

The graph below shows a simulated theoretical time evolution for the three variables.

As observed in the figure, once the glucose is depleted, the concentration of fluorescent protein increases from a basal value. Compare this results with Yeast fluorescence results

"

"