Team:Calgary/Project/FRED/Prototype

From 2012.igem.org

Hello! iGEM Calgary's wiki functions best with Javascript enabled, especially for mobile devices. We recommend that you enable Javascript on your device for the best wiki-viewing experience. Thanks!

Prototyping a Biosensor Device

In order to put our toxin-detecting bacteria to use, we developed our Functional Robust Electrochemical Detector (FRED). This involved research and development of the necessary circuitry, hardware and software. After assembling many prototypes and designs, we have developed a portable and affordable hardware-software package that uses our bacteria for chemical detection. This field-ready system can be used for quick and quantitative analysis of samples and can measure the concentrations of multiple toxic compounds simultaneously.

Last year, the Calgary iGEM team developed a potentiostat circuit whose function was quite limited. In essence, the device could run only half of the desired voltage sweep, and was inconsistent and lacking in sensitivity. Rather than give a quantitative measurement of a given compound, the primitive prototype could only produce a voltammogram with peaks that had to be interpreted by the user.

This year, we significantly improved the design and function of the potentiostat. We also designed and developed hardware for housing the circuitry and samples, as well as a software package for controlling the hardware and analyzing data for a quantitative result. Below is an overview of the components of this system, as well as details of their development and use.

The Potentiostat

A potentiostat is a piece of hardware used to conduct eletroanalytical experimentation. It controls a three electrode cell and is useful for investigation of redox reactions, especially in the context of cyclic voltammetry (see electroreporting). The electrical potential of a working electrode is maintained at a constant value with respect to the reference electrode by adjusting the current at a counter electrode.

Due to the nature of our bacteria’s response to the toxic compounds we aim to detect, we needed a potentiostat for our biosensor. However, traditional laboratory potentiostats have a few significant drawbacks:

Expense: commercial potentiostats often cost thousands of dollars, with some in the tens of thousands of dollars

Size: although newer models are smaller (and more costly), most commercial potentiostats are very large pieces of hardware

Immobility: In addition to being very bulky and heavy, most commercial potentiostats require a 120 V power outlet and are not designed for portability

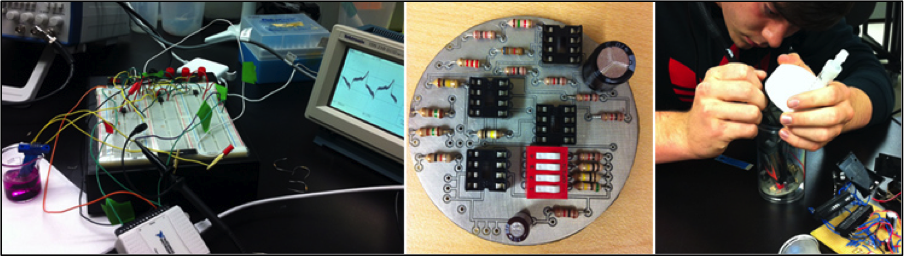

In order for our biosensor to be viable for use in the field (i.e, samples in/around Alberta Oil Sands Tailings Ponds) we needed it to be inexpensive, small, and portable. This led us to investigate the possibility of assembling our own customized potentiostat. We came across a paper (Gopinath & Russel, 2006) that described a simple, inexpensive design for a three-electrode potentiostat. This informed the design of last year’s potentiostat circuit which achieved portability through the use of 9 V batteries, but was limited in its function. This year, we made many upgrades: we tweaked the circuit to run in our desired -2 V -> 2 V sweeping range, added hardware filters to eliminate noise in our readings, implemented a variable dip switch for changing resistors values and measurement sensitivity, and had it milled onto a compact and durable circuit board with a diameter of only 6 cm.

The Hardware

One of the main goals of the biosensor was a compact and portable design. Our preliminary designs were relatively small, battery powered and had exposed electrodes that were inserted into a beaker of solution. One of our more seriously developed prototypes was a black box that housed the circuitry and the DAQ, featured power switches and indicator LEDs.

As we continued to compact the potentiostat circuit, the designs continued to get smaller and more lightweight.

Another consideration we made pertained to containment of the bacteria. We developed a disposable cartridge system that allows for safe and easy sampling, while remaining relatively inexpensive. One of the main features of our final prototype is the material we used. Rather than having our design manufactured for a pretty penny, we used supplies and materials that were readily available to us. The main shell of the biosensor is a cylindrical plastic Nalgene container, and the disposable cartridges have been built into 15 mL falcon tubes. The Nalgene shell houses the potentiostat circuit, two 9 V batteries, and a port for the insertion of cartridges. Each cartridge is a sealed vessel containing our bacteria. It houses one end of an electrode strip on the interior, and the other end protrudes from the exterior for connection to the circuit. There is also a one-way valve for injection of samples, so the exposure to the bacteria is lessened.

Include more about final design, features, etc.

The Software

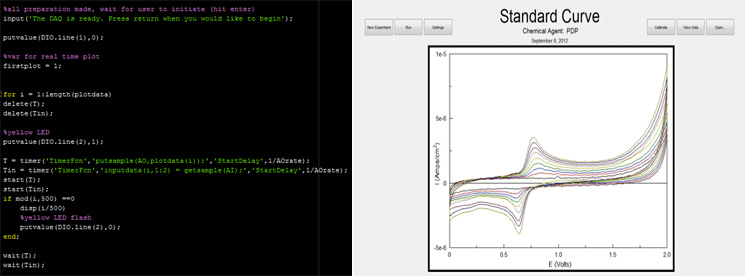

To run our hardware, we developed a personalized software package with the MATLAB platform. Software was required to run the DAQ’s inputs and outputs, as well as to interpolate the data acquired and format it nicely for the user to view.

There were several outputs that needed to be operated through the software, mainly the initial voltage sweep that was the basis of our potentiostat, as well as the three indicator LEDs. All of this was possible through our simple, yet sophisticated software package. Within this package it is easy for the user to enter a wide range of voltage sweeps they would like to test in, as well as the rate of each sweep. This package also outputs a holding voltage, so when the program is finished executing, the electrodes don’t get damaged.

Along with the outputs there were two input channels. One input channel measured the voltage applied to the solution, while the other one measured the current after the solution. Although this was the easiest part of the software to write, the more challenging issue was the interpolation of this acquired data. With our software, it is possible to produce a standard curve as well as determine the concentration of whatever chemical agent we are testing for.

All of this software is completely stand-alone, built with MATLABs own compiler, and includes a functional Graphical User Interface (GUI), for easy modification of parameters.

"

"