Team:Calgary/Notebook/Bioreactor

From 2012.igem.org

Week 1 (May 1-4)

Successfully completed both WHIMS and Biosafety level one training which provided us with training to ensure we are conducting laboratory work in a safe manner.

Week 2 (May 7-11)

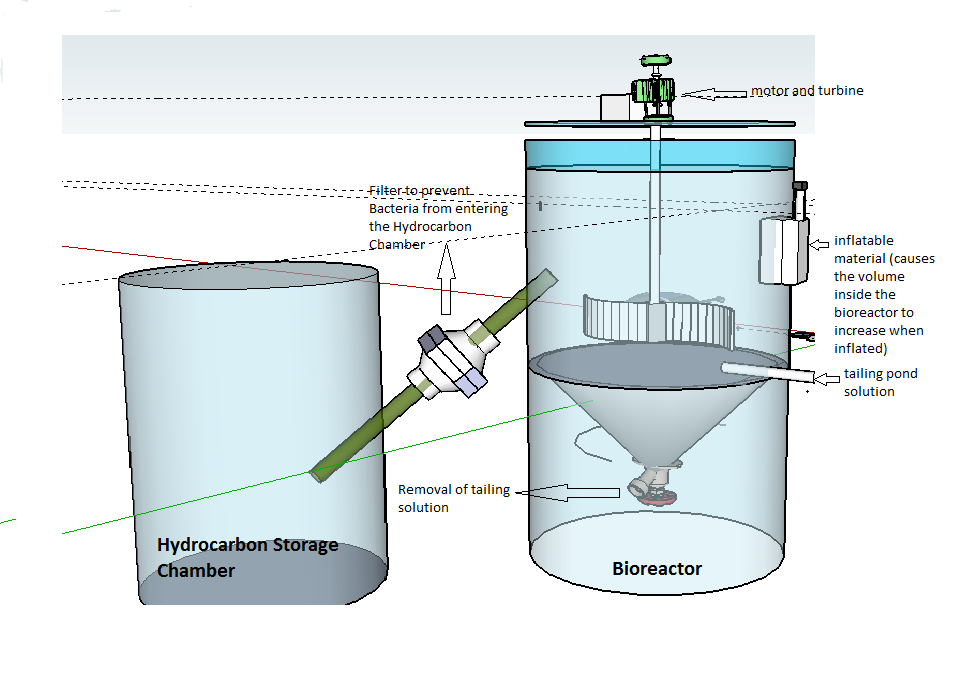

We began reading papers on Bioreactors to get a better understanding of the different types of Bioreactors and filtration methods. We were considering the use of either a dynamic membrane filter or a micro filter. There is still much we need to learn about Bioreactors.

Week 3 (May 14-18)

This week we looked into ways to remove the floating hydrocarbon layer (produced by the bacteria from Naphthenic Acids) in a Bioreactor. Some methods included a vacuum skimmer with a rocker, a vacuum with a mesh, and even exit chambers. To learn more about current Bioreactors and considerations that should be made in their design we borrowed books on Bioreactor designs from the university library. We began reading them and also started to research cream separation techniques, which was suggested to be a good model for out project. This process could work however centrifuging highly toxic tailing pond liquid doesn’t seem feasible due to the energy requirements. In addition the hydrocarbon layer would naturally separate from the tailing pond solution being less dense and hydrophobic.

Week 4 (May 14-18)

Week 5 (May 28-June 1)

We spent the early part of the week researching how oil companies separate hydrocarbons from crude oil. The intent of this research was to see if a process in commercial use could be used to help extract the hydrocarbons efficiently from our bioreactor system. One method found was a process called fractional distillation. This process is used most commonly in oil refineries to separate each type of hydrocarbon from a mixture of crude oil. The mixture is fed into a furnace where it is converted into vapor. As the vapor rises up a long column, hydrocarbons condense at different heights onto special trays depending on their boiling point. The separated liquid hydrocarbons are then transported out of the system via pipes. Another method we came across was the use of oil skimmers used to clean up oil spills. Special hydrophobic material attached to a conveyer belt collects the oil and transports it out of a body of water. This hydrophobic material was ordered online to prototype the oil skimming method with our bioreactor. In addition, we worked on learning how to use Maya, a computer modeling and animation program. We will use this program to create an animation showing the function of our bioreactor, which will be used in the iGEM competition.

Week 6 (June 4-8)

We continued working through online Maya tutorials to help design an animated clip showing the function of our bioreactor. On Tuesday, June 5th, we were given a tour of the Bonnybrook Wastewater Treatment Plant. This gave us the opportunity to observe and learn the cleaning techniques used by this plant. One of the more interesting techniques we observed was the use of UV radiation as a final cleansing method. This inspired us to include the use of UV radiation as a possible method to ensure that our bacteria do not escape the bioreactor system. In addition, during the team meeting on Friday, June 8th, Iain mentioned the possibility of using ozonation to kill the bacteria rather than UV radiation.

"

"